Welded Steel Pipe ERW for Oil Tube Good quality Factory

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 12000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1、Structure of Seamless Pipe ASTM A106/53:

carbon seamless steel pipes are widely used in gas, water and oil, transpotation;constructions;Bridge,highway,windows of model steel door; building materials;fences;heating facilities Fluid Pipe;conduit pipe,scaffolding pipe.etc.

Payment Terms: L/C D/A D/P T/T

.

2、Seamless Pipe ASTM A106/53 Specification:

Standard | GB, DIN, ASTM ASTM A106-2006, ASTM A53-2007 |

Grade | 10#-45#, 16Mn 10#, 20#, 45#, 16Mn |

Thickness | 8 - 33 mm |

Section Shape | Round |

Outer Diameter | 133 - 219 mm |

Place of Origin | Shandong, China (Mainland) |

Secondary Or Not | Non-secondary |

Application | Hydraulic Pipe |

Technique | Cold Drawn |

Certification | API |

Surface Treatment | factory state or painted black |

Special Pipe | API Pipe |

Alloy Or Not | Non-alloy |

Length | 5-12M |

Outer Diameter | 21.3-610mm |

Grade | 20#, 45#, Q345, API J55, API K55, API L80, API N80, API P110, A53B |

Standard | ASME, ASTM |

3、Packaging & Delivery

Packaging Details: | seaworthy package,bundles wrapped with strong steel strip |

Delivery Detail: | 15-30days after received 30%TT |

4、FAQ of Seamless Pipe ASTM A106/53:

1.How is the quality of your products?

Our products are manufactured strictly according to national and internaional standard, and we take a test

on every pipe before delivered out. If you want see our quality certifications and all kinds of testing report, please just ask us for it.

Guaranteed: If products’ quality don’t accord to discription as we give or the promise before you place order, we promise 100% refund.

2.Why should you chose us?

Chose happens because of quality, then price, We can give you both.Additionally, we can also offer professional products inquiry, products knowledge train(for agents), smooth goods delivery, exellent customer solution proposals.Our service formula: good quality+good price+good service=customer’s trust

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem.

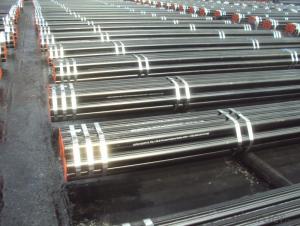

5、Seamless Pipe ASTM A106/53 Images:

- Q:What is the role of steel pipes in the transportation of petroleum products?

- Steel pipes play a crucial role in the transportation of petroleum products. These pipes are specifically designed to withstand the high pressure and extreme temperatures associated with the transportation of oil and gas. One of the main roles of steel pipes in this process is to provide a reliable and secure conduit for the transportation of petroleum products over long distances. They are used to create pipelines that span hundreds or even thousands of miles, connecting oil fields, refineries, and distribution centers. Steel pipes are preferred for this purpose due to their strength, durability, and resistance to corrosion. The high tensile strength of steel allows these pipes to withstand the immense pressure exerted by the petroleum products as they flow through the pipelines. Additionally, steel pipes have the ability to withstand extreme temperatures, ensuring the safe transportation of hot crude oil or refined petroleum products. Furthermore, steel pipes are highly resistant to corrosion, which is a critical factor given the corrosive nature of petroleum products. The pipes are often coated with protective materials, such as epoxy or polyethylene, to further enhance their resistance to corrosion. This helps to prevent leaks or ruptures that could lead to environmental damage or safety hazards. Steel pipes also offer cost-effective and efficient transportation of petroleum products. They have a smooth interior surface, which reduces friction and allows for a more efficient flow of oil or gas. This, in turn, helps to minimize energy consumption and maximize the throughput of the pipeline system. In summary, the role of steel pipes in the transportation of petroleum products is to provide a reliable, secure, and efficient means of transporting oil and gas over long distances. They are designed to withstand high pressure, extreme temperatures, and corrosion, ensuring the safe and efficient delivery of petroleum products from production sites to refineries and distribution centers.

- Q:What is the difference between Schedule 40 and Schedule 80 steel pipes?

- The main difference between Schedule 40 and Schedule 80 steel pipes lies in their wall thickness. Schedule 40 pipes have a thinner wall, making them suitable for low-pressure applications, while Schedule 80 pipes have a thicker wall, making them suitable for high-pressure applications.

- Q:Can steel pipes be used for mining applications?

- Yes, steel pipes can be used for mining applications. Steel pipes are commonly used in the mining industry for various purposes. They are often used for transporting fluids, such as water or slurry, in mining operations. Steel pipes are known for their durability, strength, and resistance to corrosion, making them suitable for underground mining environments where conditions can be harsh and corrosive. They can withstand high pressure and are able to handle the heavy loads associated with mining applications. Additionally, steel pipes can be easily welded and connected, allowing for efficient installation and maintenance. Overall, steel pipes are a reliable and cost-effective choice for mining applications.

- Q:Are steel pipes suitable for potable water systems?

- Yes, steel pipes are suitable for potable water systems. They are known for their durability, strength, and resistance to corrosion, making them an excellent choice for transporting and distributing clean drinking water. However, it is important to ensure proper coating and maintenance to prevent any potential contamination or degradation of water quality.

- Q:What is the fire rating of steel pipes?

- Several factors determine the fire rating of steel pipes. Steel possesses inherent fire resistance due to its high melting point and low thermal conductivity. However, the fire rating of steel pipes can be further improved by employing fire-resistant coatings or insulation materials. These additional measures can offer different levels of fire protection, typically quantified by how long the pipes can retain their structural integrity during a fire situation. The precise fire rating of steel pipes may differ depending on the thickness and type of coating or insulation employed. To ascertain the appropriate fire rating requirements for specific applications, it is crucial to refer to industry standards, such as those established by organizations like the National Fire Protection Association (NFPA), or consult with fire safety professionals.

- Q:What are the environmental impacts of steel pipe manufacturing?

- The environmental impacts of steel pipe manufacturing include the extraction of raw materials such as iron ore and coal, leading to habitat destruction and increased carbon emissions. The manufacturing process itself involves high energy consumption and releases greenhouse gases, contributing to climate change. Additionally, the disposal of waste materials and chemicals used during production can contaminate soil and water sources if not handled properly. Overall, steel pipe manufacturing has significant environmental implications that need to be addressed through sustainable practices and technologies.

- Q:How are steel pipes graded?

- Steel pipes are graded based on several factors to determine their quality and suitability for specific applications. The grading system for steel pipes typically includes parameters such as the chemical composition, mechanical properties, manufacturing method, and testing standards. 1. Chemical composition: Steel pipes are graded based on the elements present in their composition. This includes the amount of carbon, manganese, phosphorus, sulfur, and other alloying elements. The chemical composition greatly influences the pipe's strength, corrosion resistance, and other properties. 2. Mechanical properties: The mechanical properties of steel pipes are crucial for determining their strength, flexibility, and resistance to pressure and temperature. These properties include tensile strength, yield strength, elongation, hardness, and impact toughness. Pipes with higher mechanical properties are generally graded higher. 3. Manufacturing method: Steel pipes can be manufactured using various methods, such as seamless, welded, or ERW (Electric Resistance Welding). The manufacturing method affects the pipe's integrity, dimensional accuracy, and overall quality. Seamless pipes, for example, are considered to have higher quality due to their uniformity and absence of weld seams. 4. Testing standards: Steel pipes are graded based on their adherence to specific testing standards. These standards ensure that the pipes meet the required quality criteria and are suitable for their intended applications. Common testing standards include ASTM (American Society for Testing and Materials), API (American Petroleum Institute), and EN (European Norms). Based on these factors, steel pipes are often graded using alphanumeric codes or specifications. For instance, pipes used in oil and gas industry may be graded as API 5L (American Petroleum Institute) or pipes used for structural purposes may be graded as ASTM A500 (American Society for Testing and Materials). In conclusion, steel pipes are graded based on their chemical composition, mechanical properties, manufacturing method, and adherence to testing standards. These grades help customers and manufacturers in selecting the appropriate pipes for specific applications, ensuring safety, durability, and efficiency in various industries.

- Q:How are steel pipes used in the construction of wind farms?

- Steel pipes are commonly used in the construction of wind farms to support and secure the wind turbines. These pipes serve as the foundation for the turbines, providing stability and structural integrity. They are used to create the tower structure, which supports the nacelle and rotor blades. Additionally, steel pipes are used for transporting and distributing the electrical cables within the wind farm, ensuring efficient transmission of electricity generated by the turbines.

- Q:What does seamless steel tube mean? What are the main uses? What are the classifications?

- Seamless steel pipe having a hollow cross section, used as a conduit for conveying fluids, such as pipelines for transporting petroleum, natural gas, gas, water, and certain solid materials. Compared withsteel and roundsteelinsolid, flexural torsional strength in the same time, the weight is light, is a kind of economic section steel, widely used in the manufacture of structural parts and mechanical parts, such as the oil pipe, automobile transmission shaft, the bicycle frame and steel construction with scaffold with steel pipe manufacturing ring parts can be improved the utilization rate of materials, simplify the manufacturing process, material saving and working hours, has been widely used to manufacture steel tube.

- Q:Can steel pipes be used for underwater applications?

- Yes, steel pipes can be used for underwater applications. Steel is a strong and durable material that can withstand the harsh conditions of underwater environments, making it suitable for various applications such as offshore oil and gas exploration, underwater construction, and marine infrastructure. Additionally, steel pipes can be coated with protective layers to prevent corrosion and ensure long-term performance underwater.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Welded Steel Pipe ERW for Oil Tube Good quality Factory

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 12000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords