Weaving Machinery F

- Loading Port:

- China Main Port

- Payment Terms:

- TT

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 2 Sets Per Month set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

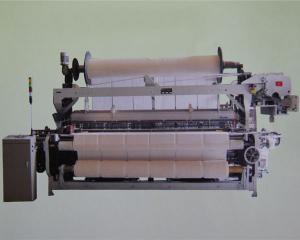

Packaging & Delivery of Weaving Machinery F Packaging Detail: STANDARD EXPORT WOODEN PACKING . Introduction of Weaving Machinery F Specification of Weaving Machinery F 1. special medical gauze & bandage weaving machine,plain fabric 2. Machine working width:150cm 3. Fabric max width:145cm 4. Fabric min width:80cm 5. R.P.M:500-600 6. Mechanical take-up,mechanical let-off 7. Thread count:7-20pick per inch 8. Cotton yarn:25s-40s 9. warp beam diameter:800mm ,cloth roller diameter will be 800mm at most. 10. if install big package,the cloth roller diameter will be 1200mm at most. 11. Production capacity:depends on thread count and R.P.M e.g thread count is 15pick per inch,R.P.M is 600.the production per hour should be 61m/h Mostly,the production capacity is more than 1000 meter per day. 10. loom motor power:1.3kw 11. electricity consumption:1.5kw/h 12. air consumption:0 13.one air pump is installed in the machine

Delivery Detail: 30 DAYS AFTER RECEIVED ALL ADVANCE

weaving machine is used to weave crude fibre(cotton,wool,hemp),chemical fibre and blending yarn etc.

- Q:What is the working principle of centrifugal fans?

- Centrifugal fans can be made of both right and left. From the motor side of the face: the impeller clockwise rotation, known as the right rotating fan; impeller counterclockwise rotation, known as the left rotating fan.

- Q:What is the car blower?

- In the operation of the pressure difference using the blower automatically lubricated to the drip nozzle, drip into the cylinder to reduce friction and noise

- Q:What is the difference between high pressure air blower and medium pressure air blower?

- High-pressure fan, also known as high-pressure blower, is different from the general centrifugal blower fan.

- Q:What are the characteristics of high-pressure axial fans?

- 4. Oil-free pollution-free impeller rotation, not with any part of the parts contact, free lubrication, it can guarantee 100% pollution-free

- Q:How to reduce fan noise?

- (1) intake air interference due to the presence of the front vane or metal mesh.

- Q:High altitude on the blower flow, pressure impact?

- The air volume according to the design requirements of the wind pressure according to the design value and then by the density ratio of the standard value of the pressure value of the selected example of the design value of working conditions 80 degrees C air volume 10000m3 / h wind pressure 2000pa 80 degrees C ...

- Q:What is the difference between a wind knife and an air knife?

- Air knife is the name suggests is to use air to dry, such as air compressor and so on.

- Q:What is the basic principle of an axial fan?

- The guide vanes change the deflected airflow into axial flow and introduce the gas into the diffuser tube, further converting the kinetic energy of the gas into pressure energy, and finally introducing the working line.

- Q:What types of fans are usually divided into?

- (Hereinafter referred to as push-in fan) and explosion-proof motor placed outside the flow channel or in the flow channel, the explosion-proof motor placed in the explosion-proof sealing chamber of the extraction of local fan (hereinafter referred to as the extraction fan ).

- Q:What is the working principle of the suction blower?

- The principle of suction can also fan example, the blade side of the compressed air, the back of the air density is reduced, the need to add air to restore the original balance

1. Manufacturer Overview |

|

|---|---|

| Location | Yantai, China |

| Year Established | 1997 |

| Annual Output Value | 500Setyear |

| Main Markets | Mid East; Eastern Europe; Westen Europen |

| Company Certifications | ISO 9001 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Qingdao |

| Export Percentage | 40% |

| No.of Employees in Trade Department | 1000 People |

| Language Spoken: | English; Chinese |

| b)Factory Information | |

| Factory Size: | 50000square meters |

| No. of Production Lines | Above20 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average |

Send your message to us

Weaving Machinery F

- Loading Port:

- China Main Port

- Payment Terms:

- TT

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 2 Sets Per Month set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords