WDS Low Conductivity Microporous Insulation Board Temperature Reduction from 950 to 240℃

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4480 pc

- Supply Capability:

- 30000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of Microporous Insulation Board:

CMDS Microporous Insulation Board is specially designed for steel industry & metallurgy with very good thermal and mechanical properties. The formulation is an opacified blend of filament reinforced pyrogenic silica. The coverings is water repellent to assure the stability of the microporous board when moisture may occur due to castables, mortar etc.

2.Main features of Microporous Insulation Board:

◆ Extremely low thermal conductivity ◆High compressive strength

◆ High thermal stability ◆Environment protection

◆ Easy to handle ◆No harmful inhalable fibers

◆ Resist most chemical attacks ◆Free of organic binders

◆ Non combustible

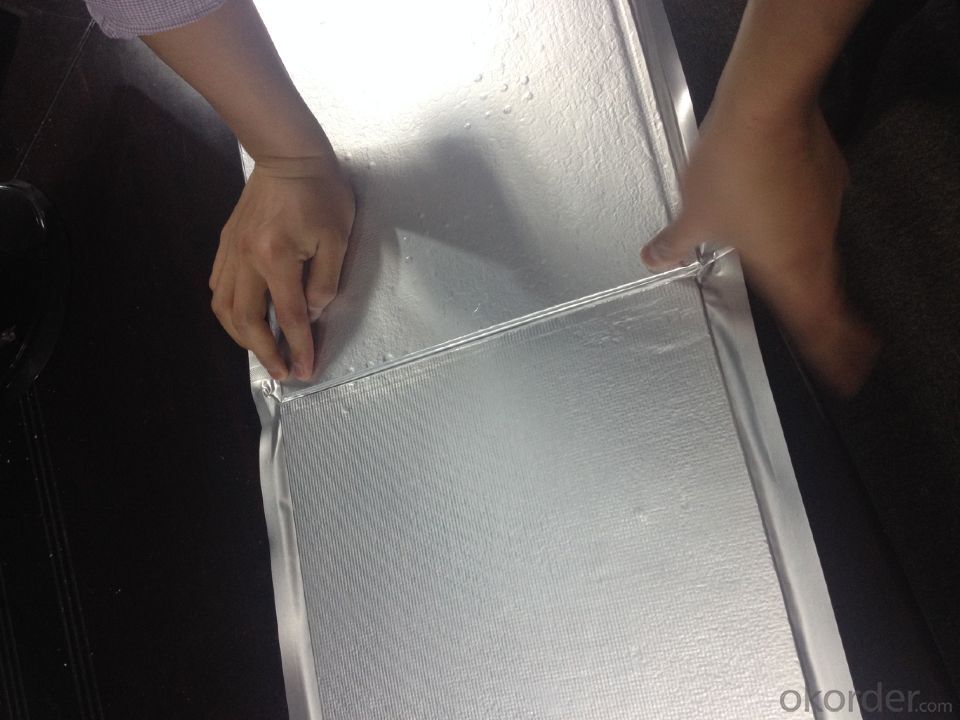

3. Microporous Insulation Board Images:

4. Microporous Insulation Board Technical Parameters

CMDS Microporous Insulation Board can be shaped easily with a simple cutter and taped off with aluminum tape. The board can be fixed in place with the same adhensives that are used for refractory lining.

Application: Ladle, Torpedo Ladle, EAF, Degassers, Cement Rotary Kiln, Ceramic Firing Klin, Aluminum Melting and Holding Furnace and so on. If you need other application picture, please contact with us

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

① How about our board?

A world class manufacturer & supplier of Microporous Insulation Board is one of the large scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system every link from raw material to final product we have strict quality test; We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q:A complete set of basement waterproof construction program

- 2.2 site preparation 2.2.1 external wall of the pull bolts should be cut off in advance, wooden blocks removed after the use of cement mortar smooth. 2.2.2 grass-roots should be clean, concrete joints processing flat, made at the corner of the yin and yang ...

- Q:How do you make waterproofing in the kitchen and bathroom?

- Kitchen and toilet to do waterproof, it is recommended to use kitchen and toilet waterproof paste, it is specifically for the kitchen and toilet water and easy to seepage yin and yang angle, pipe, sanitary ware, floor drain and other parts of the development, special materials, so waterproof Ordinary waterproof material is better, and waterproof coating construction is more convenient, only need to brush 2-3 times, the thickness of 1.2-1.5MM on it. Specific construction methods are as follows: 1, will penetrate the root, floor drain and other cracks, need to repair the site cut into "V" shape, and clean, sprinkler moist; 2, the [infiltration of crystalline repair mortar] add water (water and ash weight ratio of 1: 2 ~ 3) mixed evenly, in the early condensate before (5 minutes) to repair the construction, the root of the pipe, the floor drain, yin and yang, Should be made r angle; 3, repair mortar after the final setting, the [durable waterproof paste] powder and liquid material mixing evenly, put it aside for 3 minutes, and then stir evenly after brushing on the base surface, should be cross brush twice, and so on The first time after the dry, can be carried out the second time construction; 4, after the completion of anti-stamped, 48 hours after the closed water test.

- Q:Roof leakage, what materials do the best waterproof

- Treatment is: large cracks available plugging the king, a small crack can be used to fill the glass glue, repair with a wall waterproofing agent, after spraying a few words on it. As the external walls of cracks and cracks need high-altitude operations, the public must ask the professional construction team to deal with, to prevent accidents. Roof leakage what materials: available SBS modified asphalt - polyester film coil, polyester film SBS-3mm, laying the coil. Roof waterproofing membrane, in addition to SBS modified asphalt, there are three EPDM coil, neoprene. Can also use architectural ointment, cement, polyurethane coating. You can also use asbestos net also do waterproof. If the cement roof cracks, I suggest you use cf-2000 efficient composite waterproofing agent. In the concrete like scraping putty scraping 5mm thick again, you can play a waterproof repair function. Can also slot repair.

- Q:How can the toilet waterproof works fail?

- Use 755 new waterproof material can be painted three times. There is also a new type of waterproof material is water-like brush is also three times, you can go to the building materials market to see, you know.

- Q:Nanning building waterproof material market where

- This depends on what you need packaging materials, and if it is some packaging rope or paper or process raw materials and other different materials to find a different place, generally sold outside the packaging is more like Nanning near the train station Or the trading market,

- Q:There is no formaldehyde in the finished putty

- Often people are talking aldehyde color change, because the formaldehyde is very polluted environment contains a lot of carcinogenic substances, so into the wall inside unknowingly become an environmental killer.

- Q:Home improvement waterproofing problem

- 2, the ground waterproof layer generally turned 20 cm. Use the shower parts generally do more than 2.2 meters.

- Q:Developers have done waterproof, decoration house also have to do it

- Carbine water to remind you: the general finished house really done by the construction unit waterproofing, but we must know: First of all, developers for the rough housing waterproofing is more casual, may use the poor waterproof performance of the material, in the construction

- Q:What material waterproofing can be mixed with cement sand

- Construction can also be used to produce waterproof pulp, waterproofing agent for the amount of cement 3 ‰ -4 ‰, the use of cement label not less than 32.5MPa.

- Q:Finished house bathroom waterproof household acceptance should be how to accept?

- 3: waterproof cement mortar leveling layer and foundation with dense, no hollowing, smooth surface, no cracks, from the sand, yin and yang angle made of circular arc.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

WDS Low Conductivity Microporous Insulation Board Temperature Reduction from 950 to 240℃

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4480 pc

- Supply Capability:

- 30000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords