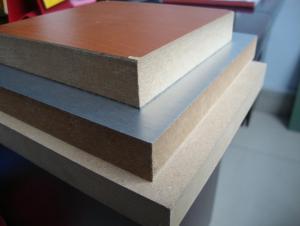

WBP Brown or Black Film Faced Plywood for Construction/Hot Sale Film Faced Plywood

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

DESCRIPTION:

| ype: | Plywoods | Place of Origin: | SHANDONG, China (Mainland) | Brand Name: | CNBM |

| Usage: | Indoor | Main Material: | Poplar | Formaldehyde Emission Standards: | E0 |

| Plywood Type: | 15-Ply Boards | Product name: | Film faced plywood | Diagonal line: | +/-2mm |

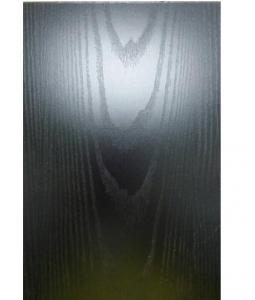

| Film: | Black/Brown Film | Surface: | Smooth/wiremeshed(anti-slip) | Cycle life: | 6-20times |

SPECIFICATION:

Product Name | Film Faced Plywood | |

Size | 1220*2440MM/1250*2500MM | |

Length(width) tolerance | +/-1mm | Thickness 9-30mm |

Diagonal line | +/-2mm | Thickness tolerance +/-0.5mm |

Film | Black/Brown Film | |

Logo | Logo-Comaccord, Customized logo by customers. | |

Surface | Smooth/wiremeshed(anti-slip) | |

Core material | Materials:Poplar/birch/combi/hardwood(eucalyptus) | |

Glue | WBP(Weather/boil proof)/Melamine/MR | |

Density | 550-700kg/cbm | |

Cycle life | 6-20times | |

Moisture | 6-12% | |

Warpage | <=1% | |

Edge | Sealed with water-proof paint, and different colors are available for us | |

Pallets | Pts/40'GP:16 pallets | Pts/40'HQ:18 pallets |

Veneer layers (longitudinal grain with transverse grain crossed, glue-sprayed among each layers) | 9mm:5 or 7 layers | 12mm:7 or 9 layers |

15mm:9 or 11 layers | 18mm:11 or 13 layers | |

21mm:13 or 15 layers | 25mm:15 or 18 layers | |

Hot press | Only two time hot preseed (Different: two times hot pressed plywood-smooth surface, one time hot pressed-low cost and cheap price), Comaccord only produce high quality product. | |

Capacity | 500-1000m3/day | |

FEATURE:

1. We have 20 years of experience in export board.

2. We are professional in the manufacturing wood board.

3. We can offer you competitive price with lowest cost but good quality.

PICTURES:

- Q:What are the types and usage of interior panels?

- Patterns require a clear texture, wood grain symmetry, no obvious color, no digging, no dead, no sand injury, smooth and smooth; Ruled plywood requires texture straight, no obvious color, no point of the child.

- Q:What are the types of wood panel?

- . Walnut: color from light gray to purple brown, rough texture and rich changes. Transparent paint after painting texture more beautiful, more deep and steady color. Walnut wood panels in the coating before the surface to avoid scratching white, the number of times more than the other decorative panels 1-2 Road.

- Q:What is the double-panel, wardrobe with this back to do it?

- Wardrobe backplane is best not to use plywood to harm too much. If you want to use a single side of the plywood. You can use Bin wood integrated board so environmentally friendly.

- Q:The difference between eco-board and blockboard

- The generalized eco-board is equivalent to the melamine plywood, its full name is melamine impregnated film paper facing wood-based panel, is to have different colors or textures of paper into the eco-board resin adhesive soak, and then dry to a certain degree of curing The pavement in the particleboard, moisture board, medium density fiberboard, plywood, blockboard or other hard fiber board surface, made by hot pressing plate.

- Q:What is an ecological board? Can be used to do?

- Originally used to do computer desk office furniture, mostly for the monochrome board, with the popularity of the furniture in the family, it gradually become the furniture factory preferred manufacturing materials, surface color and pattern are more.

- Q:What is the difference between a melamine plywood and a flat sheet?

- 1. moisture-proof, waterproof

- Q:Wooden door surface panels (multi-layer board) is a solid wood door or solid wood composite door?

- This is a typical composite door process. Some doors, especially in the middle of the door made of Chengdu directly wooden side, there is no MDF, and then paste the two sides of the decorative panels. Some boss said it was solid wood door.

- Q:What is the paper for pvc plywood?

- If you want to achieve the effect of decoration, then w to use color paper; if you want to play the effect of wear, then g to use wearable paper; If you want to play the effect of learning balance, then x to use balance paper.

- Q:White European furniture oak veneer good or smooth look good

- Veneer, then there will be lines. The And the general plywood will be clear water paint, a long time will be more and more oxidation of yellow. The The If you want European-style white, then it is recommended to do paint. The Put the putty on the wooden furniture and dry it with sandpaper. And then on the paint so even if the long time the oxidation of the furniture surface is white light. The

- Q:Melamine plywood and fire board panels which is good? That environmental protection?

- Fire board veneer is three layers, relatively thick, and trimer polyamine plate veneer only one layer, relatively thin.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

WBP Brown or Black Film Faced Plywood for Construction/Hot Sale Film Faced Plywood

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords