Waterproofing EPDM Pond Liner In Rolls for Roof/Garden/Poor Use

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Product Introduction:

This waterproof coiled material is of high elasticity with best performance among high polumer

waterproof coiled material in the world.It is also the most typical one in the world.Waterproof coiled material made of ternary ethylene-propylene rubber is produced withthe use of the most advanced contiuous extrusion and vulcanization technology and related equipments which are specially designed for production of such product.It is good in compactness,without bubble and performance difference in length and breadth,perfomances reach or exceedthe demands of GB18173.1-2000 standard.

2. Product Specification:

There are two installation ways.one is full sticking,the other is hot welding.

Thickness | 2mm,3mm,4mm,5mm |

Width | 1.02m/roll or customized |

Length | 10m/roll or customized |

Temprature Centigrade | -5,-10, -15, -20, -25, -30 |

Base felt/Tyre | PY,G,PYG |

Surface Material | PE film, colored sand, mineral grain, aluminum foil |

3. Technical Sheet:

Number | Item | Unit | Value | |

1 | Size Variation | Thichness | % | ±10 |

Width | % | ±1 | ||

Length | % | Allowed negative | ||

2 | Breaking tensile strength at normal temperature | Mpa | ≥7.5 | |

Breaking tensile strength at 70°C | Mpa | ≥2.3 | ||

3 | Breaking elongation at normal temperature | % | ≥450 | |

Breaking elongation at -20°C | % | ≥200 | ||

4 | Tear strength | KN/m | ≥25 | |

5 | Impermeability(30min) | * | 0.3Mpa no leakage | |

6 | Bending at low tempreture | °C | ≤-40 | |

7 | Stretch tensor at heating | Elongate | mm | ≤2 |

Shrink | mm | ≤4 | ||

8 | Air oven aging(80°C×168h) | Tensile strength at break retained | % | ≥80 |

Elongation at break retained | % | ≥70 | ||

9 | Anti-alkali | Tensile strength at break retained | % | ≥80 |

Elongation at break retained | % | ≥80 | ||

10 | Nuture weathing at manual simulation | Tensile strength at break retained | % | ≥80 |

Elongation at break retained | % | ≥70 | ||

4. Features:

1. Waterproofing EPDM pond liner has excellent resistance to environmental stress cracking resistance, aging resistance, corrosion resistance as well as long service life.

2.Waterproofing EPDM pond liner has the lowest permeability

3. Waterproofing EPDM pond liner has high elongation,heat treatment the size change is small

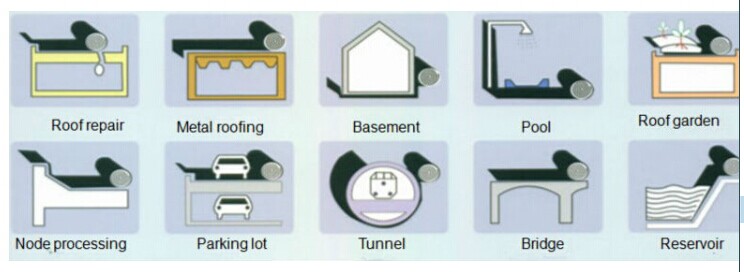

5. Product Application:

EPDM waterproof membranes form an effective barrier to liquid water or water vapor in the roof construction for industrial and civil engineering, underground engineering such as subway & tunnel, water conservancy such as water pools & ditch, shelter, grain depot, land filling, dyke and subway.

5. Some photos:

- Q:Can a waterproofing membrane be used for shower installations?

- Indeed, for shower installations, it is advisable to employ a waterproofing membrane to avert water intrusion into the walls, floors, or any susceptible areas that may result in harm. A waterproofing membrane serves as a shield, prohibiting water infiltration into the nearby regions. This is especially crucial in showers where water is incessantly utilized and splattered. By implementing a waterproofing membrane, you guarantee that your shower area remains impervious to water and safeguarded against any possible water-related destruction.

- Q:Can a waterproofing membrane be used for a school building foundation?

- Yes, a waterproofing membrane can be used for a school building foundation. Waterproofing membranes are designed to prevent water infiltration into structures, and they are commonly used in various construction applications, including building foundations. By installing a waterproofing membrane on the foundation walls, it can help to protect the building from water damage and prevent moisture-related issues such as mold, deterioration, and structural damage. This is particularly important for school buildings, as they often have extensive foundations and are subject to heavy usage and potential water exposure. Therefore, using a waterproofing membrane can be an effective solution to ensure the longevity and structural integrity of the school building foundation.

- Q:Are waterproofing membranes resistant to chlorine exposure?

- Waterproofing membranes can vary in their resistance to chlorine exposure. Some membranes are specifically designed to be resistant to chlorine and are commonly used in applications where chlorine exposure is expected, such as pool decks or water treatment facilities. These membranes are typically made with materials like PVC or TPO that have inherent resistance to chlorine and can withstand prolonged exposure without significant degradation. However, it is important to note that not all waterproofing membranes are chlorine-resistant. Some membranes, particularly those made with materials like EPDM or bitumen, may not be as resistant to chlorine and may experience deterioration or damage when exposed to chlorine for extended periods. To ensure the longevity and effectiveness of a waterproofing membrane in a chlorine-rich environment, it is crucial to select a membrane that is specifically designed and tested for chlorine resistance. Consulting with a waterproofing professional or manufacturer can help determine the most suitable membrane for the specific chlorine exposure conditions.

- Q:Can a waterproofing membrane be used on tunnels with water drainage systems?

- Tunnels with water drainage systems can indeed utilize a waterproofing membrane. The purpose of this membrane is to create a protective barrier against water infiltration and effectively prevent any leakage into the tunnel. However, it is crucial to ensure that the waterproofing membrane is compatible with the specific water drainage system in place. The installation of the membrane must be done in a manner that does not hinder or disrupt the functioning of the drainage system. Moreover, it is important to carefully consider the design and installation of the drainage system to ensure efficient water management and avoid any potential complications that may compromise the effectiveness of the waterproofing membrane. By carefully planning and executing the installation, a waterproofing membrane can effectively uphold the overall integrity and durability of tunnels with water drainage systems.

- Q:Can a waterproofing membrane be used in areas with high water pressure?

- Yes, a waterproofing membrane can be used in areas with high water pressure. Waterproofing membranes are designed to withstand and prevent water penetration, making them suitable for use in areas where there is high water pressure. However, it is important to ensure that the membrane chosen is specifically rated and designed to handle the specific water pressure levels in order to ensure its effectiveness and durability.

- Q:Are waterproofing membranes resistant to jet fuel?

- Waterproofing membranes are typically designed to resist the penetration of water and other liquids. However, jet fuel is a highly volatile and corrosive substance that can pose a significant challenge to the effectiveness of waterproofing membranes. While some waterproofing membranes may provide a certain level of resistance to jet fuel, it is generally recommended to implement additional protective measures when dealing with such hazardous materials. To ensure the maximum resistance against jet fuel, it is advisable to use specialized membranes that are explicitly designed to withstand the corrosive effects of this substance. These specialized membranes are typically made from materials such as polyurethane or epoxy, which have proven to be more resistant to jet fuel compared to standard waterproofing materials. Moreover, it is important to consider the specific application and environmental conditions when determining the resistance of a waterproofing membrane to jet fuel. Factors such as temperature, exposure time, and concentration of the jet fuel can influence the membrane's performance. Regular inspections and maintenance should also be conducted to identify any signs of degradation or potential weaknesses in the membrane. In summary, while some waterproofing membranes may offer a certain level of resistance to jet fuel, it is crucial to use specialized membranes and implement additional protective measures to ensure optimal performance and protection against the corrosive effects of jet fuel.

- Q:Are waterproofing membranes resistant to saltwater?

- Waterproofing membranes, in general, possess resistance to saltwater. Their purpose is to establish a barricade that hinders water infiltration into surfaces such as roofs, walls, or foundations. These membranes are created using materials like rubber, polyethylene, or PVC, which have an inherent ability to withstand the corrosive impact of saltwater. This resistance enables waterproofing membranes to adequately safeguard structures and surfaces against water-induced harm, even in saltwater surroundings. Nonetheless, it is crucial to select a waterproofing membrane specifically tailored for saltwater applications in order to guarantee optimal effectiveness and durability.

- Q:Can a waterproofing membrane be used in areas with chemical exposure, such as industrial settings?

- Yes, a waterproofing membrane can be used in areas with chemical exposure, such as industrial settings. However, it is important to ensure that the specific waterproofing membrane chosen is suitable for the chemicals present in the environment. Different waterproofing membranes have different levels of resistance to various chemicals, so it is crucial to select a membrane that can withstand the specific chemical exposure in the industrial setting. Additionally, proper installation and maintenance of the waterproofing membrane are essential to ensure its effectiveness and longevity in such environments. Regular inspections and prompt repairs or replacements should be conducted to address any damage caused by chemical exposure. Overall, with the right selection and maintenance, a waterproofing membrane can provide an effective barrier against water and chemicals in industrial settings.

- Q:Are waterproofing membranes suitable for underground parking garages?

- Yes, waterproofing membranes are suitable for underground parking garages. They provide an effective barrier against water infiltration, preventing damage to the structure and protecting against potential leaks and moisture-related issues. Waterproofing membranes are designed to withstand the high water pressure typically associated with underground environments, making them an ideal solution for ensuring the longevity and durability of underground parking garages.

- Q:SBS modified asphalt waterproofing membrane and synthetic polymer membrane the same, not the same, what is the difference?

- fiber fabric or fiber felt For the carcass, powdery, granular, flake or film material for the cladding material made of curled sheet waterproof material. The use of the construction process is cold construction paving or hot melt paving.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Waterproofing EPDM Pond Liner In Rolls for Roof/Garden/Poor Use

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords