Waterproofing and High Breathable Membrane

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Waterproofing and High Breathable Membrane

Introduction:

Breathable Membrane is a water resistant membrane but with high vapor permeability, use as diffusion open roofing felts under pitched roof tile or vapor permeable barrier house wraps on timber frame walls.

Breather membrane functions as a weather-resistant barrier, preventing rain from getting into the roof or wall assembly while allowing water vapor to pass to the exterior.

Breather membrane may also serve as an air barrier if it is sealed carefully at seams.

Breathable Membrane have good "water resistance", good "water vapor permeability", and good "air barrier properties". Weather Proof House Wrap.

Specification:

Surface mass density | 80 g/m² | ||

Roll size | 1.5m*50m or customized | ||

Vapor permeability | ≥2250 g/m²/24h | ||

Sd value | 0.02 m (-0.005/+0.015) | ||

Water tightness | class W1 | ||

Tensile strength MD/CD | 105/70N/50 mm (+/-20%) | ||

Tearing strength MD/CD | 50/60 N (+/-20%) | ||

Resistance to UV rays | 3 months | ||

Reaction to fire | Class F | ||

Loading quantity | 20’GP | 40’GP | 40’HC |

By bulk (1.5*50) | 1140rolls | 2450rolls | 2700rolls |

With pallets (1.5*50m) | 900rolls | 1954rolls | 2122rolls |

Jumbo rolls (1.5*3500m) | 14rolls | 30rolls | |

Advantages:

1)Excellent performance at water resistance

2)Particular function of water vapor permeability

3)Good performance at UV resistant for 3 months

4)They are much lighter than bitumen felts, suitable for construction in different condition

5)They have excellent tensile and tearing strength

6)100% recyclable

7)Simple installation in new building, re-roofing and refurbishment situations

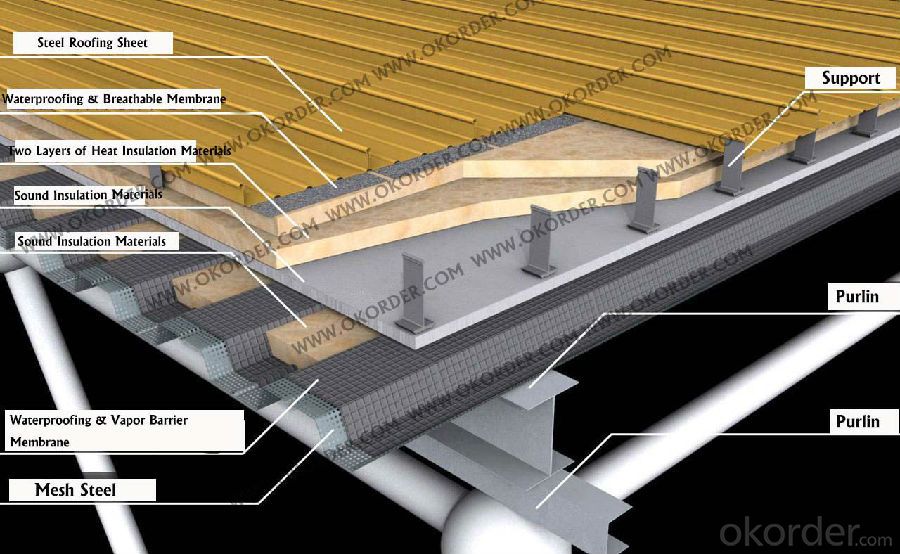

Typical Installation:

Typical Application:

FAQ:

1. Where is your factory located in?

Our factory is located in Jiangsu province, close to Shanghai.

2. Have you ever been export?

Yes, our product has been exported to many countries.

3. Can we get samples?

Yes, we are free for samples, what you need to assume is freight charge.

- Q:Bathroom first leveling or do waterproof, what is the difference

- Is the first water and then leveling. Home improvement toilet ground specific process practice: 1. The base layer, and which layer with the structural board, with cement mortar wipe. It is recommended to set the floor drain, the grassroots level should be flat and the direction of the leak to the slope. Against the wall and the root of the root should be wiped rounded.

- Q:How do you make waterproofing in the kitchen and bathroom?

- Kitchen and toilet is a relatively stable part of the home improvement structure, it is recommended to do waterproof mortar waterproofing agent on it, mortar waterproofing agent not only with the base surface bonding firm, and puncture resistance, high strength, waterproof life and construction Material with the life, the construction of relatively waterproof coating is also relatively simple.

- Q:Roof membrane waterproof construction process, what should be noted that?

- Four do not: 1 surface can not afford sand 2 surface can not afford skin 3 surface is not crisp 4 does not crack

- Q:Can Henkel have water against him?

- In order to ensure the quality of the proposed do not add water, the general finished materials are proportional, emulsion and powder, in strict proportion.

- Q:What is PE waterproof cloth and PVC tarpaulin

- PVC (tarpaulin) Features: coated high-strength polyester waterproof cloth is a high-strength polyester canvas-based cloth, coated with polyvinyl chloride (PVC) paste resin with accelerator, anti-mildew agent, anti-aging agent, anti Electrostatic agents and other chemical additives, made by high temperature plastic. Waterproof, anti-aging, anti-static and other properties; and the product breaking strength, tear elongation, tear strength is much better than the traditional tarpaulin; product appearance colorful, it is pleasing to the eye. The surface of the special treatment from the anti-skid effect, is the international popular waterproof cloth, and the width of large, reaching 2 meters wide, processing products can reduce the patchwork to improve the quality, can be used to heat sealing stitching, The And according to user needs to produce different functions, different colors, different thickness of the product.

- Q:Cabinet is to buy finished products, or directly to the decoration company to do?

- My home decoration cabinets are Haotian decorative package to do, although expensive, but still very worthwhile, all of their wood will be waterproof and moisture, in contact with the wall will do the underground waterproof and moisture, and are on-site cash Now do, timber materials can be seen directly, the amount of glue is not much, less formaldehyde, the latter part of the living is also more comfortable!

- Q:Home improvement waterproofing problem

- 1, you said the above three products are old products. It is recommended to use the latest dosage form of cf-2000 efficient composite waterproofing agent, is the latest cement-based crystalline products. Not only then to solve the leakage problem, and the composite waterproof agent in the active material in the water or moisture under the action, but also continue to penetrate into the concrete layer. The formation of 10 cm from the self-waterproof layer. If the self-waterproof layer due to external factors caused by small cracking, as long as there is water through, you can start the active substance of the secondary repair function, to automatically repair the crack water seepage.

- Q:What material waterproofing can be mixed with cement sand

- Construction can also be used to produce waterproof pulp, waterproofing agent for the amount of cement 3 ‰ -4 ‰, the use of cement label not less than 32.5MPa.

- Q:FRP finished brush on what can be waterproof do not fade

- With glass fiber reinforced plastic + color paste even after the use of. Can be waterproof.

- Q:Finished house bathroom waterproof household acceptance should be how to accept?

- Bathroom waterproof acceptance: material acceptance: 1: materials need to meet the national standards, the need for a product certificate of competency. Construction acceptance: 1: grass-roots surface should be flat, no hollowing, from the sand, cracking and other defects. Base water content should meet the construction requirements of waterproof materials.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Waterproofing and High Breathable Membrane

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords