Waterproof/Waterpfoofing Membrane For Roofing

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product description

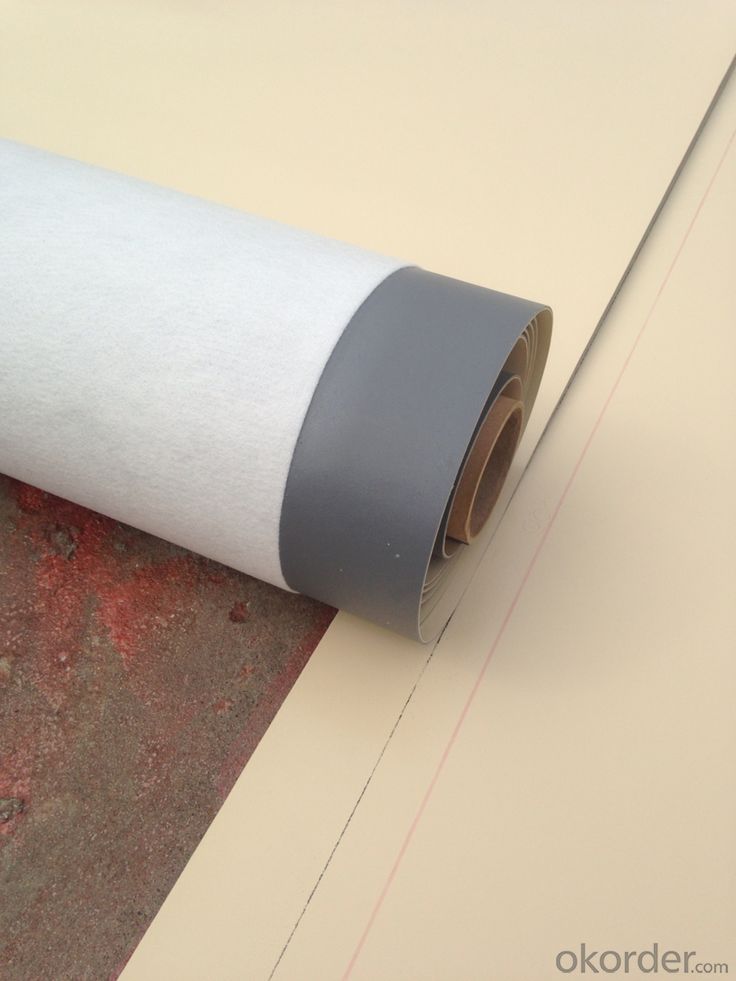

Polyvinyl chloride PVC waterproof membrane is a kind of excellent performance of polymer waterproof material,PVC resin as the main raw material,add all kinds of special additive and anti-aging composition,the use of advanced equipment and advanced technology extrusion rolling is made.The product has the tensile strength and elongation high shrinkage of small,low temperature soft good,long life and other advantages, the products wide 1.2m to 3.0m, the thickness of 0.8-2.0 mm(special specifications can be customized),stable performance,reliable quality,construction is convenient.

Application Scope

The products are widely used in all kinds of civil construction,subway,tunnel,water conservancy,landfill site,chemical industry,metallurgy and other areas of waterproof seepage control,corrosion engineering

Features:

Excellent anti-aging property.

Puncture- resistant.

Welding construction,

High tensile strength, good elongation, good dimensional stability.

Good plasticity.

It has self-extinguishing from fire property.

Materials surface is smooth, fast color, stain resistance.

More wide, Wastage become less when being used.

Type:

N1—Exposed PVC waterproof membrane.

(It is mainly used as details treatment for exposed roof waterproof project)

N2—Non-exposed PVC waterproof membrane.

(It is mainly used as details treatment for non-exposed roof waterproof project)

L1—Exposed PVC waterproof membrane with fabric

(It is mainly used for exposed roof waterproof project)

L2—Non-exposed PVC waterproof membrane with fabric.

(It is mainly used for non-exposed roof waterproof project)

W1—Exposed reinforced PVC waterproof membrane .

(It is mainly used for steel structure roof exposed waterproof project)

W2—Exposed reinforced PVC waterproof membrane .

(It is mainly used for steel structure roof non-exposed waterproof project)

Advantages

Technical Parameters

No. | Item | Index | |||||

| 1 | Thickness of resin layer of the middle fabric ,mm≥ | - | - | 0.40 | 0.40 | 0.40 | |

| 2 | Tensile performance | Max tensile strength,N/cm ≥ | - | 120 | 250 | - | 120 |

| Tensile strength,NPa ≥ | 10 | - | -10 | - | - | ||

| Max elongation% ≥ | - | - | 15 | - | - | ||

| Breaking elongation % ≥ | 200 | 150 | - | 200 | 100 | ||

| 3 | Heat treatment size change rate%≤ | 2.0 | 1.0 | 0.5 | 0.1 | 0.1 | |

| 4 | Cold bonding | -25°c No cracks | |||||

| 5 | Watertightness | 0.3mPa,2h waterproof | |||||

Packaging & Shipping

product show

FAQ

Q: What's the delivery time ?

A: 3-5 days for 1-600 rolls, 10-15 days for container.

Q: What's the payment terms ?

A: TT/LC

Q: How do you make replacement with quality problems ?

A: New replacement will be packed into your next order or send to you directly after receive video or photo about quality problems.

- Q:Can a waterproofing membrane be used on precast zinc surfaces?

- Yes, a waterproofing membrane can be used on precast zinc surfaces. The membrane will provide an additional layer of protection against water infiltration, helping to maintain the integrity of the surface and prevent water damage.

- Q:Can a waterproofing membrane be used in swimming pools?

- Indeed, the utilization of a waterproofing membrane in swimming pools is widespread. To avert water leakage, it is a customary practice to incorporate waterproofing membranes during the construction or refurbishment of swimming pools. These membranes possess an exclusive design that enables them to function as a barrier against water infiltration, guaranteeing the pool's impermeability and leak-free condition. Typically, these membranes are crafted from robust materials like PVC, EPDM, or polyurethane, which exhibit resistance to water, chemicals, and UV rays. Furthermore, their flexibility allows them to effortlessly conform to the pool's shape and contours, providing a seamless and enduring waterproofing solution.

- Q:What is the typical installation process for a waterproofing membrane?

- Installing a waterproofing membrane typically involves several steps. Firstly, the surface requiring waterproofing is thoroughly cleaned and prepared by eliminating any existing coatings, debris, or loose materials. It is essential to guarantee that the surface is smooth, clean, and devoid of any contaminants that may hinder the membrane's adhesion. Secondly, any cracks, holes, or imperfections in the surface are repaired. This entails filling cracks with a suitable filler or patching compound and smoothing out rough areas. It is crucial to have a solid and even surface to ensure proper installation and efficacy of the waterproofing membrane. Once the surface is prepared, it is often necessary to apply a primer to enhance adhesion between the surface and the membrane. The primer is typically applied using a brush or roller, following the manufacturer's instructions. After the primer has dried, the waterproofing membrane is mounted. There are various types of membranes available, such as sheet membranes or liquid-applied membranes. Sheet membranes are usually rolled out onto the surface and adhered using an appropriate adhesive or mortar. Liquid-applied membranes are applied using a brush, roller, or spray equipment to create a continuous and seamless barrier. Throughout the installation process, it is crucial to ensure correct membrane installation with proper overlap or seams. Additionally, any penetrations or transitions must be adequately treated and sealed. This includes areas such as corners, edges, drains, and pipe penetrations, where additional detailing may be necessary to create a watertight seal. Once the membrane is installed, it is important to allow it to cure or dry according to the manufacturer's instructions. This ensures that the membrane reaches its maximum strength and waterproofing capabilities. Finally, after the membrane has cured, it may be beneficial to apply a protective layer or coating to enhance the durability and longevity of the waterproofing system. This may involve applying a topcoat, sealant, or protective barrier to shield the membrane from UV rays, foot traffic, or other potential sources of damage. In summary, the installation process for a waterproofing membrane includes surface preparation, primer application, membrane installation, detailing and sealing, curing, and potentially applying a protective layer. It is crucial to adhere to the manufacturer's instructions and consult with a professional if necessary to ensure proper and effective installation.

- Q:Can a waterproofing membrane be used on stone surfaces?

- Yes, a waterproofing membrane can be used on stone surfaces. Stone surfaces, such as natural or manufactured stone, can benefit from the application of a waterproofing membrane to prevent water penetration and protect against moisture-related issues. Waterproofing membranes are designed to create a barrier against water and other liquids, preventing them from seeping into the stone and causing damage. This can be particularly important for exterior stone surfaces that are exposed to rain, snow, and other weather conditions. Additionally, using a waterproofing membrane on stone surfaces can help prolong the lifespan of the stone by reducing the risk of cracks, spalling, and other forms of deterioration caused by water absorption. It is essential to choose a waterproofing membrane specifically formulated for stone surfaces to ensure proper adhesion and long-lasting protection.

- Q:Can a waterproofing membrane be used on tunnels with vehicular traffic?

- Yes, a waterproofing membrane can be used on tunnels with vehicular traffic. Waterproofing membranes are designed to provide a barrier against water infiltration, protecting the structure from potential damage caused by moisture. In tunnels with vehicular traffic, water can seep through the concrete and cause corrosion, deterioration, and even compromise the structural integrity of the tunnel. By applying a waterproofing membrane, it creates a protective layer that prevents water from penetrating the tunnel walls, roof, and floor. This helps to extend the lifespan of the tunnel and ensures the safety of vehicles passing through. However, it is essential to select a waterproofing membrane specifically designed for heavy traffic conditions to withstand the constant load and wear. Additionally, proper installation and regular maintenance are crucial to ensure the effectiveness and longevity of the waterproofing system in tunnels with vehicular traffic.

- Q:Can waterproofing membranes be used on metal surfaces?

- Indeed, it is possible to utilize waterproofing membranes on metal surfaces. The purpose of waterproofing membranes is to establish a barrier that obstructs the infiltration of water into surfaces, regardless of their composition. Since metal surfaces are susceptible to corrosion and water-related harm, the application of a waterproofing membrane can safeguard them against moisture and prolong their lifespan. The choice of waterproofing membrane may vary depending on the precise needs and specifications of the metal surface; nevertheless, there are several options specifically engineered for metal applications. These membranes typically possess flexibility, durability, and resistance to UV rays and other environmental factors, thereby ensuring enduring protection for the metal surfaces.

- Q:Does a waterproofing membrane require a primer before application?

- In order to apply a waterproofing membrane, it is necessary to use a primer. The purpose of a primer is to improve the adhesion between the membrane and the substrate, guaranteeing a strong bond. Additionally, it acts as a sealant that protects the surface, preventing any moisture or impurities from affecting the efficiency of the waterproofing system. For a reliable and enduring waterproofing solution, it is crucial to apply a primer prior to the membrane.

- Q:Can a waterproofing membrane improve energy efficiency?

- Yes, a waterproofing membrane can improve energy efficiency. A waterproofing membrane acts as a barrier against moisture intrusion, preventing water from seeping into the building envelope. By keeping the structure dry, it helps to prevent the growth of mold and mildew, which can contribute to poor indoor air quality and the deterioration of building materials. In addition to protecting against moisture, a waterproofing membrane can also provide insulation benefits. Many waterproofing membranes are designed to have a high thermal resistance, or R-value. This means that they can provide an extra layer of insulation to the building, reducing heat transfer through the walls or roof. By improving the building's thermal performance, a waterproofing membrane can help to reduce the load on heating and cooling systems, resulting in energy savings and improved energy efficiency. Furthermore, a waterproofing membrane can also help to reduce air leakage in a building. Air leakage can account for a significant amount of energy loss, as conditioned air escapes through gaps and cracks in the building envelope. By sealing off these areas, a waterproofing membrane can help to improve the building's air tightness, reducing energy loss and improving energy efficiency. Overall, a waterproofing membrane can play a crucial role in improving energy efficiency by preventing moisture intrusion, providing additional insulation, and reducing air leakage. Investing in a high-quality waterproofing system can lead to long-term energy savings, improved indoor comfort, and a more sustainable and efficient building.

- Q:Are there different waterproofing membrane options for above-ground and below-ground applications?

- There is a variety of waterproofing membrane options available for above-ground and below-ground applications. When it comes to above-ground applications, structures like roofs, balconies, or walls require waterproofing. In these cases, commonly used membrane options include liquid-applied membranes, sheet membranes, and polyurethane membranes. These membranes are designed to withstand weather elements, such as UV rays, temperature changes, and foot traffic. On the other hand, below-ground applications involve waterproofing structures like basements, foundations, or tunnels. Below-ground waterproofing membranes are specifically designed to withstand hydrostatic pressure from the surrounding soil and groundwater. These membranes are typically thicker and more durable compared to above-ground membranes. Bituminous membranes, bentonite clay membranes, and composite membranes are commonly used options for below-ground waterproofing. Selecting the appropriate waterproofing membrane for each specific application is crucial due to varying requirements and challenges. Seeking advice from a waterproofing professional or engineer can assist in determining the most suitable membrane option for both above-ground and below-ground applications.

- Q:Is a waterproofing membrane resistant to hydrocarbons or oil spills?

- Yes, a waterproofing membrane is generally resistant to hydrocarbons or oil spills.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Waterproof/Waterpfoofing Membrane For Roofing

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords