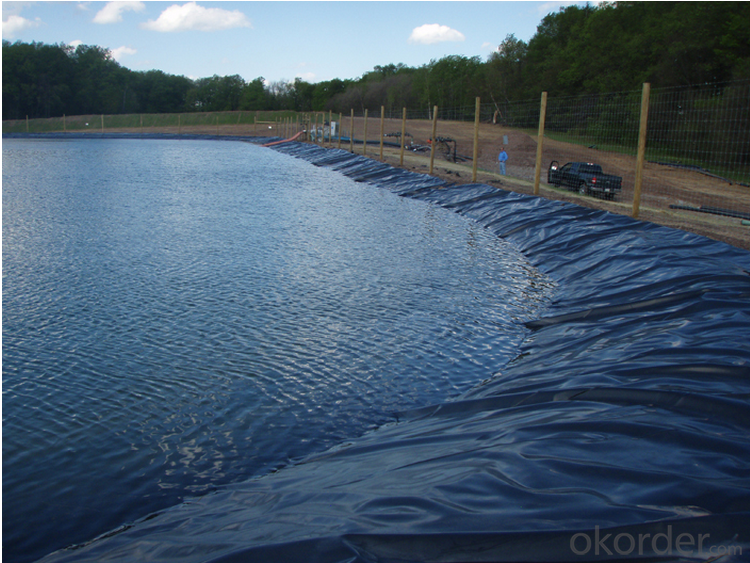

waterproof polyethylene film,waterproof geomembrane, black hdpe geomembrane

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 900000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Features

Good mechanical properties, high tear strength, deformation and adaptable, puncture resistance, anti-aging, anti-ultraviolet-resistant, Anti oil and salt, pH, anti-corrosion, high temperature-resistant, non-toxic, long service life. water, drainage, seepage, the good effect of moisture, width, thickness of the full range of specifications and low cost, simple construction.

Applications

1) Environmental protection, sanitation (such as solid waste landfills, sewage treatment plants, power plants Chi-conditioning, industrial, hospital solid waste, etc.) .

2) Water (such as rivers, lakes and reservoirs of the anti-dam, plugging, reinforcement of the canal seepage, the vertical wall of the heart, slope protection, etc.).

3) Municipal Engineering (subway, on the ground floor of the building, planted roof, the roof garden of anti-seepage, sewage pipes lining, etc.).

4) Landscape (man-made lake, river, reservoir, golf courses reservoirs of the substrate, slope protection, green lawn of the waterproof moisture, etc.).

5) Petrochemical (chemical plants, oil refineries, gas storage tanks of the anti-chemical reaction tanks, sedimentation tanks of the lining, etc.).

6) Mining (washing and pool heap leaching, the ash-field, dissolved, precipitation, the yard, the tailings seepage substrates, etc.) .

4. ASTM HDPE geomembrane technical index

No. | Item | Test Value | ||||||

0.75mm | 1.0 mm | 1.25 mm | 1.5 mm | 2.0 mm | 2.5 mm | 3.0mm | ||

1 | Minimum Density(g/cm³) | 0.939 | ||||||

2

| Tensile Property | |||||||

Strength at yield,N/mm | 11 | 15 | 18 | 22 | 29 | 37 | 44 | |

Strength at break ,N/mm | 20 | 27 | 33 | 40 | 53 | 67 | 80 | |

Elongation at yield,% | 12 | |||||||

Elongation at break,% | 700 | |||||||

3 | Tear Resistance N | 93 | 125 | 156 | 187 | 249 | 311 | 374 |

4 | Puncture Resistance N | 240 | 320 | 400 | 480 | 640 | 800 | 960 |

5 | Stress Crack Resistance, hrs | 300 | ||||||

6 | Carbon Black Content, % | 2.0-3.0 | ||||||

Carbon Black Dispersion | 1 or 2 | |||||||

7 | Standard OTI Min | 100 | ||||||

High Pressure OTI Min | 400 | |||||||

8 | Impact Cold Crack at -70°C | Pass | ||||||

9 | Water vapor permeability (g.cm/cm2 .s.Pa) | ≤1.0×10-13 | ||||||

10 | Dimensional Stability (%) | ±2 | ||||||

FAQ

How about the delivery time?Lead time since receipt of 30% T/T deposit payment: 3 weeks.(Samples will be prepared within 3 days.)

2.What's are the MOQ?Generally speaking, the MOQ is one container, but we can provide you samples for quality inspection.

3. Do you charge for the samples?Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

4. Can you produce according to customers' design?Sure, we are professional manufacturer, OEM and ODM are both welcome.

- Q:Is the coated glass useful?

- Quality is ok, it is very cost-effective after all.

- Q:What is the tensile strength of a geomembrane?

- The tensile strength of a geomembrane refers to its ability to withstand pulling or stretching forces without breaking or tearing. This strength is typically measured in units of force per unit width, such as pounds per inch (lb/in) or newtons per meter (N/m). The specific tensile strength of a geomembrane can vary depending on its composition, thickness, and manufacturing process.

- Q:How do geomembranes withstand temperature variations?

- Geomembranes are designed to withstand temperature variations through their unique composition and structure. They are made from materials that have a high resistance to temperature changes, such as polyethylene or polyvinyl chloride (PVC). These materials have excellent thermal stability, allowing them to remain durable and flexible across a wide range of temperatures. Additionally, geomembranes are often reinforced with additives and reinforcements that further enhance their ability to withstand temperature fluctuations. This combination of materials and reinforcements enables geomembranes to maintain their integrity and functionality even in extreme hot or cold conditions.

- Q:How do geomembranes contribute to the preservation of endangered species?

- Geomembranes can contribute to the preservation of endangered species by creating protective barriers that prevent contamination of their habitats. These impermeable liners are often used in landfills or waste containment facilities to prevent leakage of harmful substances into the environment, helping to maintain the quality of water sources, soil, and air. By ensuring the integrity of ecosystems, geomembranes indirectly support the survival and well-being of endangered species by safeguarding their habitats from pollution and degradation.

- Q:How many kinds does the films of glass door?

- High transparent ceramic materials: glass film processed into nano particles deposited into; that adhere to the highest transmittance and the maximum can absorb solar energy. This type of film reflectivity is very low, the insulation is attributed to the high rate, high power in the world of commodity. Called IR type heat reflective film. Usage: glass film metal function layer after interlayer or magnetron sputtering plating skills made, with the intention to reach many reflected solar radiation heat and light. Heat reflective glass film has outstanding shading function and heat insulation function, make indoor light soft and comfortable. The one-way perspective: the glass film metal function layer through the interlayer or magnetron sputtering techniques the plating is made, with the highest reflection of solar radiation and visible light function. Facing the light side with mirror characteristics, the opposite perspective. This can appearance reflective layer mirror effect and color of the building Decoration effect of good, namely, one-way perspective type with reflection translucency and pleochroism. Perspective: that adhere to the high transparency, but also cut off from the inevitable heat from the sun, is modern buildings throughout the use of glass membrane type. Widely used in commercial and residential buildings.

- Q:Can 1.5mm geomembrane be produced by blow molding?

- Yes. The film reaching the standard is all produced by blow molding.

- Q:European electrothermal?film is good

- electrothermal?film is made of polyester film. When working with electrothermal?film as a heating element, the heat is sent into space in the form of radiation, the human body and the object first get warm, and the combined effect is better than traditional convection heating. The European electrothermal?film is one of the good quality product among all types. it is good for the use.

- Q:How to deal with the dust in the mobile phone film?

- If the dust particles are attached on the protective film, you also can use the scotch tape to stick it away, but you cannot blow away the dust with gas. It is possible to cause more dust particles to attach on the protective film by the use of air blowing, and the dust particles can not be blown away. Correct way of treatment is that a hand hold the film by the scotch tape, the other hand use the scotch tape to quickly stick the dust, and then you can continue to stick the film. In the process of removing the dust, you do not directly contact the inner surface of the film by your hands, otherwise it will leave oil that can not be cleaned.

- Q:What are the advantages of the glass reflective film?

- It is anti-ultraviolet, can block more than 95% of ultraviolet rays, and while insulating heat, it can reduce the damages to household articles and people's skin caused by ultraviolet rays. These are the main reasons why consumers like it, It is healthier: The adhesive inside the glass reflective film contains UV (ultraviolet) absorbent which can block 98%-99% of UV rays. It is safer. For the ordinary heat-insulating film, it has certain security enhancement, and meanwhile can stick to debris like the reflective clip (adhesive) glass. It is better than toughened glass in security.

- Q:What are the advantages and disadvantages of membrane pressure cupboard drawer?

- mould pressing board has the advantages of rich colors, realistic wood grain, monochrome chroma brilliant, not cracking and no deformation. the plastic uptake board is sealed into one part, and it doesn't need to seal the edge, solving the chip problem after sealing edge for a long time. the disadvantage of mould pressing board it can not be a long time to contact or close to the high temperature objects, while the design of the main body can not be too long, otherwise it is easy to deform. In the kitchen, it had better not to smoke, the cigarette temperature will burn hurt the film plate surface.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

waterproof polyethylene film,waterproof geomembrane, black hdpe geomembrane

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 900000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords