Waterproof Painting for Roof Vertical Wall

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 1000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Single Component Polyurethane Waterproof Coating Introduction

Single-component moisture-curing pure polyurethane waterproof coating is a kind of liquid polymer waterproof material,

suitable for dry and wet base surface construction, solidified into tough and elastic, non-toxic and tasteless waterproof

film after coating. It is a new type of environmental friendly waterproof material without solvent.

Single Component Polyurethane Waterproof Coating Application

•Building roof

•Concrete

•Wall

•Water Tank Structure

•Floor(kitchen floor, bathroom floor ect)

•Underground Tunnel

•Sewerage Structure

•Movement Joint

•Wet Area, Pipes, Sewer & etc.

Single Component Polyurethane Waterproof Coating Advantage

1.water based and solvent based

2.Solid content above 80%

3.Durable performance, UV resistant, ageing-resistant,resistant high and low temperature,antifatigue, withstand constant immersion in water

4.Good splicing performance

5.Operate conveniently, low viscosity

6.Can splicing with concrete and many kinds board stuff

7.Will not change color after used

8.Apply for Roof,Swimming Pool,Tank and more

Single Component Polyurethane Waterproof Coating Specifications

NO. | Items | Ⅰ | Ⅱ |

1 | Tensile Strength MPa≥ | 1.9 | 2.45 |

2 | Elongation at Break %≥ | 550 | 450 |

3 | Tearing Strength N/mm≥ | 12 | 14 |

4 | Bend at Low Temperature°C≤ | -40 | |

5 | Unpermeability0.3MPa 30min | Impermeable | |

6 | Solids Content%≥ | 80 | |

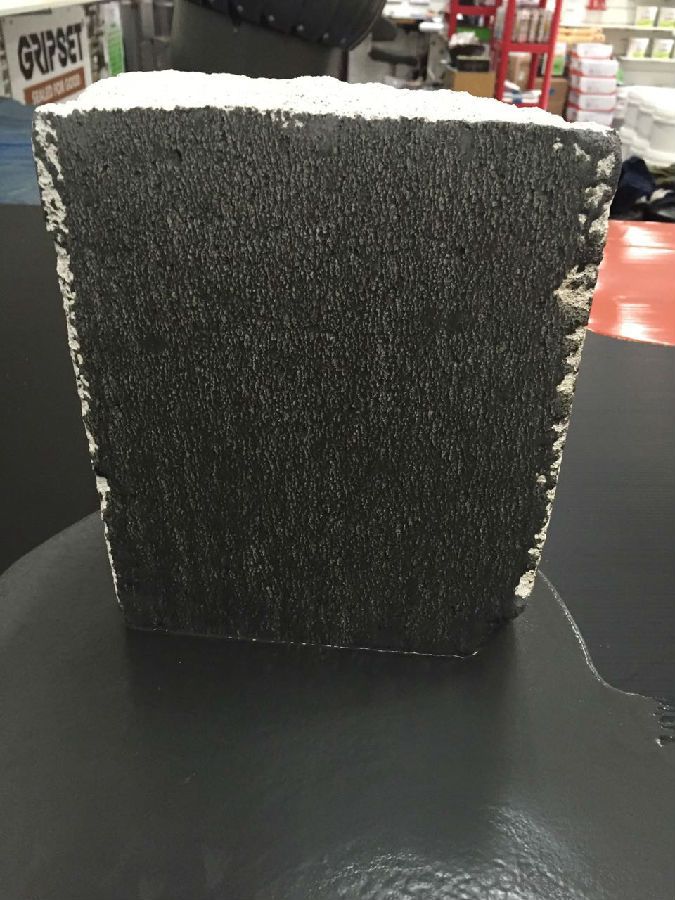

Single Component Polyurethane Waterproof Coating photos

FAQ

1. Which payment do you accept?

For you convenience, our payment can be L/C, TT

2. Is free sample available?

We can supply free samples. You'll just need to pay for express cost.

3. How about your quality?

We have strict quality control system, we make testing on incoming raw material and finished products. Your third party testing is also welcomed. With high quality, our products are used on government projects at home and abroad. Our product quality is accepted by clients from all over the world. Warmly welcome your samples requirement or trail order.

- Q:Slope roof drains do not need to be waterproof

- The overall rigid waterproof layer is often due to these small structural nodes handled properly, resulting in the failure of the entire roof waterproof.

- Q:How can the toilet waterproof works fail?

- After the failure of the bathroom waterproofing project to solve the specific needs of the specific analysis of targeted treatment. ??????? Bathroom waterproof is the problem more decoration works. The main reasons are: 1, construction (local, details, etc.); 2, waterproof material problems; 3, the structure (such as uneven settlement, cracking, etc.); 4, to save a little waterproof waterproof measures. ???????? After the three must be redo waterproof, the first type of reasons can be used to the appropriate remedial measures, pay the table "bathroom waterproof failure part of the phenomenon and the remedy list." ??????? Please responsible professionals in the field to carefully check the judge to find specific reasons for dealing with the need to destroy the red or must be destroyed, do not affect others after causing greater losses. The following are the same as the "

- Q:What is PE waterproof cloth and PVC tarpaulin

- PE tarpaulin, anti-aging, anti-aging, anti-corrosion, light, easy to fold, relative to the PVC tarpaulin, PE tarpaulin cheaper price for the freight yard, the service life will be shorter.

- Q:There is no formaldehyde in the finished putty

- Visible putty powder and formaldehyde or a great relationship, but now many manufacturers have introduced environmentally friendly putty powder, not only environmentally friendly pollution-free important is also can control the air, there is a negative ion putty powder is the composition which contains tourmaline tourmaline, through And the water molecules in the air combined with the decomposition of negative ions to deal with the air, anion can be neutralized with formaldehyde into dust falling into the air, you can also remove the dust in the air, as well as enhance the metabolism of the function.

- Q:Home improvement waterproofing problem

- 5, the kitchen is designed to be waterproof. In principle, there should be water and water treatment should be done to avoid the water pipe out of the problem, affecting the destruction of downstairs decorating

- Q:What is the price of a waterproof window cover?

- The benefits of window sets (1) the most important role of the window cover is to protect the role of the window. Because long-term use is easy to make the window side of the phenomenon of damage, and window cover made of wood, can play a good anti-collision protection. (2) the design of the window cover to a certain extent also played with the door sets, baseboard echoes the effect, because they are with the whole space, the common bear the role of income side. (3) window cover is the form of the windowsill match, we shop a piece of marble and the like things on the windowsill, often feel more monotonous and abrupt. Plus hood, the feeling will be more complete. Window cover style features: window cover and the door is echoes, in general, if the door is no door sets, then the window does not need window sets; the other hand, if there is no door sets and no window cover, there is a no completed The feeling that, in most cases, the requirements of the style of the window cover and the same door uniform.

- Q:Waterproof mortar expensive or dry mortar expensive

- Cationic neoprene latex is a polymer modified polymer anti-corrosion system. By the introduction of imported epoxy resin modified latex by adding the domestic neoprene emulsion and polyacrylate, synthetic rubber, various emulsifiers, modified latex and other components of the polymer latex.

- Q:What material waterproofing can be mixed with cement sand

- Waterproof layer used in the cement label of not less than 32.5MPa, the thickness of cement mortar should be 2-3cm, the surface clean and solid without cracks; mortar leveling layer of cement should not be less than 32.5MPa, leveling layer to smooth compaction, finished product maintenance is not low In 5 days.

- Q:Can acrylic materials be perforated? How to do waterproof after punching?

- Anti-corrosion nine PCT board size is greater than the size of the hole, that is, just in the hole on the nine-plate, This can play a certain role in strengthening.

- Q:Js waterproof coating without powder can brushing

- 2. Mixing and mixing: JS waterproof coating: cement = 1: 0.8 weight ratio of mixing, fully stirred to no particles, uniform mortar can be used; in the course of the application to adhere to intermittent mixing, to prevent layered deposition ;

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Waterproof Painting for Roof Vertical Wall

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 1000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords