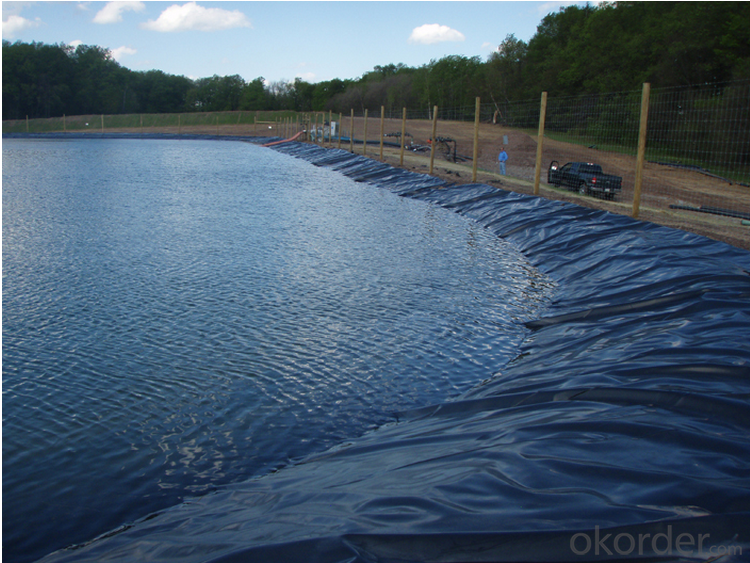

Waterproof HDPE liner/Geomembrane liner/fish pond liner roll

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 900000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

We can produce all models of high density polyethylene waterproof HDPE geomembrane liner for landfills, such as composite geomembrane, HDPE geomembrane, ECB geomembrane, EVA geomembrane, PVC geomembrane, smooth geomembrane, textured geomembrane, fish pond liner roll, geomembrane line, etc.

Characteristic

1.Good mechanical properties, high tear strength, deformation and adaptable, puncture resistance, anti-aging, anti-ultraviolet-resistant, Anti oil and salt, pH, anti-corrosion, high temperature-resistant, non-toxic, long service life.

2.Water, drainage, seepage, the good effect of moisture, width, thickness of the full range of specifications and low cost, simple construction.

Applicable scope

1) Environmental protection, sanitation (such as solid waste landfills, sewage treatment plants, power plants Chi-conditioning, industrial, hospital solid waste, etc.) .

2) Water (such as rivers, lakes and reservoirs of the anti- dam, plugging, reinforcement of the canal seepage, the vertical wall of the heart, slope protection, etc

3) Municipal Engineering (subway, on the ground floor of the building, planted roof, the roof garden of anti-seepage, sewage pipes lining, etc.).

4) Petrochemical (chemical plants, oil refineries, gas storage tanks of the anti-chemical reaction tanks, sedimentation tanks of the lining, etc.).

Project | Index | |||

GL | GH | |||

GL-1 | GL-2 | GH-1 | GH-2 | |

Tensile strength (MPa) | ≥14 | ≥17 | ≥14 | |

Break elongation (%) | ≥400 | ≥450 | ≥400 | |

Right angle tear strength (N/mm) | ≥50 | ≥80 | ≥50 | |

Carbon black content (%) | ≥2 | |||

Water vapor permeability coefficient (g.cm/(cm.s.Pa) | ≤1.0x10-12 | |||

-70 Low temperature brittleness properties | pass | |||

Dimensional stability (%) | ±3 | |||

FAQ

How about the delivery time?Lead time since receipt of 30% T/T deposit payment: 3 weeks.(Samples will be prepared within 3 days.)

2.What's are the MOQ?Generally speaking, the MOQ is one container, but we can provide you samples for quality inspection.

3. Do you charge for the samples?Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

4. Can you produce according to customers' design?Sure, we are professional manufacturer, OEM and ODM are both welcome.

- Q:What kind of mobile phone stick membrane is good?

- At present, the mobile phone beauty in mobile phone stick membrane mainly has four kinds of material: PP material, PVC material, PET material, arm material. PP material stick membrane is soft, and the translucency is also poor and it does not have the function of anti-scratch, anti abrasion, it can only prevent dust, since the result is not good, now it is basically abandoned by consumers. PVC material stick membrane is soft and easy to paste, but it is relatively thick, and the transparent performance is not very good. And if you tear the stick membrane, it may leave a defective gum on the mobile phone screen, affecting the appearance. stick membrane of PET material has high transmittance, leaving no defective gum on the screen after tearing, and it will not appear the small bubble in the middle of stick membrane. But the stick membrane reflection is a little higher, so that the users can't see the words on the screen, and easy to leave fingerprint on the surface, etc. Arm material, the membrane surface of this material is processed by the latest technology, having the ability of wear-resistant and scratch resistant. At the same time, this material has no bubble after pasting, and the light transmission is also very good, after tearing it will not leave any traces. Relatively speaking, the effect of this membrane is the best, and the price is the most expensive.

- Q:How do geomembranes contribute to wetland and pond restoration?

- Geomembranes contribute to wetland and pond restoration by providing a barrier that prevents water from seeping into the ground or escaping from the area. This helps to create and maintain the necessary water levels and conditions for the growth of wetland vegetation and the establishment of a healthy pond ecosystem. Additionally, geomembranes can be used to contain and control the movement of contaminated water, helping to prevent pollution and protect the surrounding environment during restoration efforts.

- Q:Are geomembranes suitable for use in reservoirs?

- Yes, geomembranes are suitable for use in reservoirs. They are highly effective in preventing leaks and seepage, providing excellent containment for water storage. Geomembranes also offer durability and resistance to UV radiation, chemicals, and biological factors, making them a reliable choice for long-term reservoir applications.

- Q:How do geomembranes handle chemical spills?

- Geomembranes are designed to effectively handle chemical spills by acting as a barrier to prevent the hazardous substances from contaminating the surrounding environment. They have excellent chemical resistance properties, which enable them to withstand the corrosive effects of various chemicals. Additionally, geomembranes are impermeable, meaning they do not allow the chemicals to seep through, ensuring containment and preventing further spread. This makes them ideal for containment applications, such as chemical storage facilities, hazardous waste sites, and industrial areas prone to spills.

- Q:Water pond impermeable or membrane geomembrane.

- geomembrane and impermeable membrane film called both with the same kinds of products like water ponds geomembrane HDPE (High Density Polyethylene) Material Material HDPE geomembrane seepage effect in addition to having good outside with higher puncture resistance, tear resistance, resistance to current standard of ability HDPE geomembrane two standard type that is standard (GB / T17643-2011 GH-I), marking the second type (GB / T17643-2011 GH-II) using standard like ordinary water pond HDPE geomembrane according to user type from the water depth with procurement thickness HDPE geomembrane.

- Q:What are the requirements for geomembrane welding?

- The requirements for geomembrane welding include having a suitable welding machine, proper training and certification, a clean and well-prepared surface, appropriate welding temperature and pressure settings, and the use of compatible welding materials. Additionally, the welder should possess good technique, attention to detail, and knowledge of specific welding procedures and standards.

- Q:Does the geomembrane be used as an experiment?

- Geomembrane is to do the experiment, in general, geomembrane manufacturers need to do factory experiments, substandard products can not be manufactured, when the geomembrane transported to the site, the site of the site will do their own experiments, and some sites Will be sent to a dedicated testing organization to do the experiment, the general experiment to take six samples of testing, about each batch of goods to do an experiment 1, test purposes 1. To test the different materials geomembrane solderability and adhesiveness. 2. The welding operators to carry out professional training, so that welding operators to master the geomembrane welding machine technical parameters, working principle, operating procedures and seams of the quality standards, skilled operation of geomembrane welding machine. 3. Determine the welding temperature, crawling speed and operation method of the welding machine under different material conditions. 4. Determine the "T" type lap welding method. 5. Determine the type of adhesive used in geomembrane bonding, manufacturer and construction process. 6. In determining the welder model, welding temperature, crawling speed and other welding construction technology, geomembrane joints of the indicators meet the specification requirements. 7. In determining the binder model, the manufacturer and the construction process, the geomembrane joints of the indicators meet the regulatory requirements. 8. To determine the quality of geomembrane seams detection methods, so that the test staff master master geomembrane seams quality control and testing methods, standards and testing frequency

- Q:Can geomembranes be used in reservoirs and dams?

- Yes, geomembranes can be used in reservoirs and dams. Geomembranes are impermeable liners that are designed to contain liquids or prevent seepage. They can be installed in reservoirs and dams to provide a barrier to prevent water leakage, enhance water storage capacity, and protect against erosion and contamination.

- Q:How to stick the front of the mobile phone film?

- The step 1 of sticking the mobile phone film: First, use the fibre cloth in the package to clean up the dust on the surface of the screen, you should wipe it in order, but do not wipe back and forth; notice: You must first clear off the small cloth or wool cloth of the small fiber cloth, and then to wipe. Step 2: Generally, there is three layers of screen film, you should select the appropriate size, and tear off the "release liner" at the bottom layer, (the middle layer is actually useful), and then align at the LCD screen and carefully paste it down. Step 3: Stick the film and press it to purge the air under the plate, it is better to use the special tools. Step 4: You should carefully remove the air, so as not to leave the bubble and effect the beauty. Step 5: After it is pasted, you can tear off the "protective?film" at the top layer. Step 6: After the protective film is pasted, it can be used. Prompt: The light?transmittance is the most important evaluation index of the mobile phone screen protective film, when selecting the material, we must choose the regular film with good quality.

- Q:Can geomembranes be used in tunnel construction?

- Yes, geomembranes can be used in tunnel construction. They are often used as a protective layer to prevent water infiltration and provide waterproofing for tunnels. Geomembranes act as a barrier between the tunnel structure and surrounding soil or groundwater, ensuring the structural integrity and longevity of the tunnel.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Waterproof HDPE liner/Geomembrane liner/fish pond liner roll

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 900000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords