Waterproof Gypsum Board China Original Factory Price

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Descrption

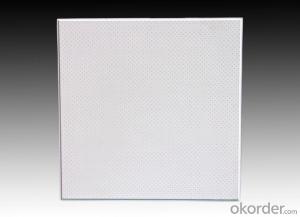

Through a high technological manufacturing process. The Gypsum Board has a character of safe, environmental, healthy, non-dust ,noxious-free, moisture-proof, sunken proof, and easy clean.It is an economical, elegant, fashionable, ceiling decorative material.

Water resistant gypsum board is commonly used as a backer for tiles. The gypsum core of the board is typically treated with a waxlike or silicone chemical substance. According to Gerald E. Sherwood and Robert C. Stroh in the book "Wood Frame House Construction," water-resistant boards can be used in high-moisture areas such as kitchens and bathrooms

Usage

This superior material is mainly used in the indoor decoration of super class buildings such as hotels, restaurants, shopping malls theaters, danceries, cinemas, stations,auditoriums, offices, sitting rooms, business buildings, electronic workshops,precision apparatus rooms and industrial or residential buildings. We have 5 series of products:Painting relievo surface Printing pellicle surfaceSuperior pellicle surface Clean non-dust surfaceAdvanced pellicle backside aluminum foil surface.

Specifications

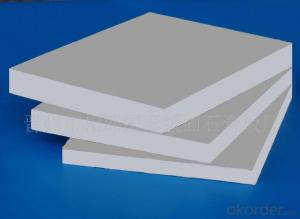

1) Material: gypsum board

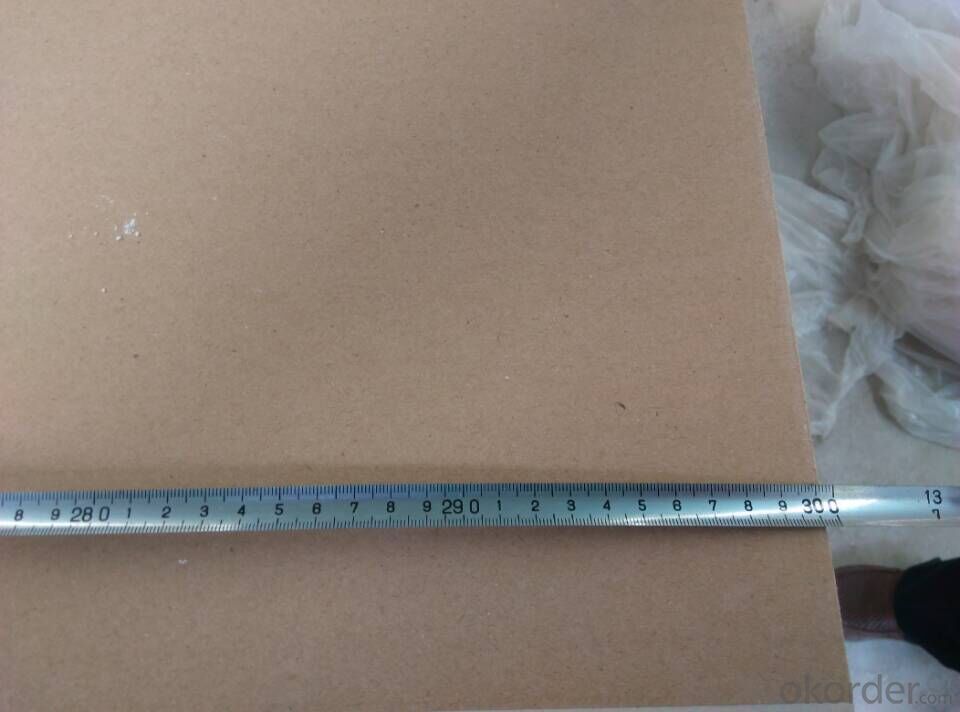

2) Thickness: 7mm-15mm

3) Sizes:

1200x2400x8.0mm

1220x2440x8.0mm

1200x2400x8.5mm

1220x2440x8.5mm

1200x2400x9.0mm

1220x2440x9.5mm

1200x2700x9.5mm

1200x3000x9.5mm

1200x2400x12mm

1220x2440x12mm

1200x2700x12mm

1200x3000x12mm

1200x2400x13mm

1220x2440x13mm

1220x2440x12.7mm

1200x2500x12.5mm

1200x2400x15mm

1220x2440x15mm

1200x2700x15mm

1200x3000x15mm

4) Weight: 7kg/sqm

5) Strength: >160N

6) Characters: non-flammable B1, in accordance with Chinese standard GB8624-1997

7) Installation: match with ceiling T-bar.

Packing

standard marine package, by wood pallet or in bulk.

FAQ

1.Q:What is your delivery time?

A :40H container Usually 7days. will be changed according to your big quantity

2.Q:Whice payment can you accept?

A: TT, LC are accepted

3.Q:What is your MOQ?

A: 100pcs. But our customer usually buy a 20' container as a trial order.

4.Q: I am interested in the products but I do not have experience

A: Tell us your budget and target market and we will give you professional advice of exact kinds and quantity.

5.Q: Can I get some samples for check?

A:Yes. Samples can be provided for free but you should take charge for the freight fee and we will deduct the cost from your first order

Picture

- Q:Gypsum board ceiling what tools

- Electric tools and general tools Accessories Power tools: air compressor, gas nail gun, hammer, electric drill (drill bit to be able to screw the kind of) If it is silicon calcium gypsum board also use cutting machine (cut the kind of tiles ), General tool accessories: ladder, tape measure, wrench, fountain, flat water line, hammer, pliers, pencil, wallpaper and so on.

- Q:Is it possible to use a gypsum board ceiling in the bathroom?

- I was also considering the kitchen and bathroom all with gypsum board ceiling .... but afraid of the above will be leaking, if a little bit of water down, my top will be demolished, so again to call the workers to get, and Is a lot of cost ... aluminum buckle board, then buckle together, better get, called property repair just fine

- Q:Gypsum board shape ceiling how to deal with yellowing

- Gypsum board shape ceiling yellowing, to figure out the reasons for yellowing, so as to be targeted to deal with: 1, floor water seepage led to damp yellowing. This situation must first solve the floor water seepage, and then the yellowing of the surface of latex paint for processing. 2, the screw rust is not handled properly and rust caused by the ceiling yellowing. Replace the rusted tapping screws and then proceed. 3, a long time natural weathering oxidation led to yellowing the ceiling. Find and solve the problem after you can repair, re-scratch the putty powder, and then brush again latex paint.

- Q:Which glue is suitable for sticky gypsum board, for a long time.

- Is the ceiling a gypsum board ceiling? Sand with the sand to polish the exposed gypsum board, clean the dust, and then glue the glass glue

- Q:Taishan brand gypsum board and can be resistant to which good

- Taishan good, can be resistant to Fu also made in China, but a lot of elements in foreign countries is not allowed, you use the Taishan it, Taishan good.

- Q:I would like to ask how much small gypsum board machinery

- If it is a paper gypsum board production line, the equipment investment should be about 200 million (less developed areas, the smallest scale) but the operating costs are huge, are high energy-consuming products (coal, electricity), especially equipment debugging period is simply burning money If it is a lot of the cost of gypsum ceilings, equipment and the like is very cheap, but this product is not suitable for the market.

- Q:Stairs on top of the gypsum board ceiling how to install 20KG heavy crystal lamp?

- Remove the gypsum board, in the concrete floor to play the expansion screw (according to the requirements of the lighting manufacturers design), no other what way. This is before the ceiling should be buried live live, should not be the error, and now can not be missed on the wrong

- Q:Light steel keel gypsum board wall how to fight line?

- This is just to find the vertical line on the line, first from the side of the wall, in the amount of a size, point a point, and then let the line down this point down to the ground, the other person to see the following line , In the ground point of a point, and then on the other side of the amount of a size you want, according to the above method on the ground and then point a point, and then on the top of the two points on the top line, the following two points bomb The ground line, and then the above points and the bottom points on the wall. If it is to the top of the partition, do not consider the level, only consider the vertical on the line,

- Q:Gypsum board which, the kind of home improvement, the kind of suitable for tooling

- Where you are in place, around the material brand is not the same, the general thickness of the wall with 12mm ceiling with 9mm, kitchen and toilet with waterproof gypsum board. Other parts with ordinary gypsum board on it.

- Q:Bathroom with gypsum board ceiling

- The bathroom environment is relatively large humidity, gypsum board moisture resistance is very poor, so the ceiling is easy to deformation, and gypsum board surface treatment are mostly latex paint, and latex paint is not suitable for wet environment, a long time there will be Peeling or moldy phenomenon

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Waterproof Gypsum Board China Original Factory Price

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords