Waterproof Coating For Roof Single Component Polyurethane

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 1000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Single Component Polyurethane Waterproof Coating Introduction

Single-component moisture-curing pure polyurethane waterproof coating is a kind of liquid polymer waterproof material,

suitable for dry and wet base surface construction, solidified into tough and elastic, non-toxic and tasteless waterproof

film after coating. It is a new type of environmental friendly waterproof material without solvent.

Single Component Polyurethane Waterproof Coating Application

•Building roof

•Concrete

•Wall

•Water Tank Structure

•Floor(kitchen floor, bathroom floor ect)

•Underground Tunnel

•Sewerage Structure

•Movement Joint

•Wet Area, Pipes, Sewer & etc.

Single Component Polyurethane Waterproof Coating Advantage

1.water based and solvent based

2.Solid content above 80%

3.Durable performance, UV resistant, ageing-resistant,resistant high and low temperature,antifatigue, withstand constant immersion in water

4.Good splicing performance

5.Operate conveniently, low viscosity

6.Can splicing with concrete and many kinds board stuff

7.Will not change color after used

8.Apply for Roof,Swimming Pool,Tank and more

Single Component Polyurethane Waterproof Coating Specifications

NO. | Items | Ⅰ | Ⅱ |

1 | Tensile Strength MPa≥ | 1.9 | 2.45 |

2 | Elongation at Break %≥ | 550 | 450 |

3 | Tearing Strength N/mm≥ | 12 | 14 |

4 | Bend at Low Temperature°C≤ | -40 | |

5 | Unpermeability0.3MPa 30min | Impermeable | |

6 | Solids Content%≥ | 80 | |

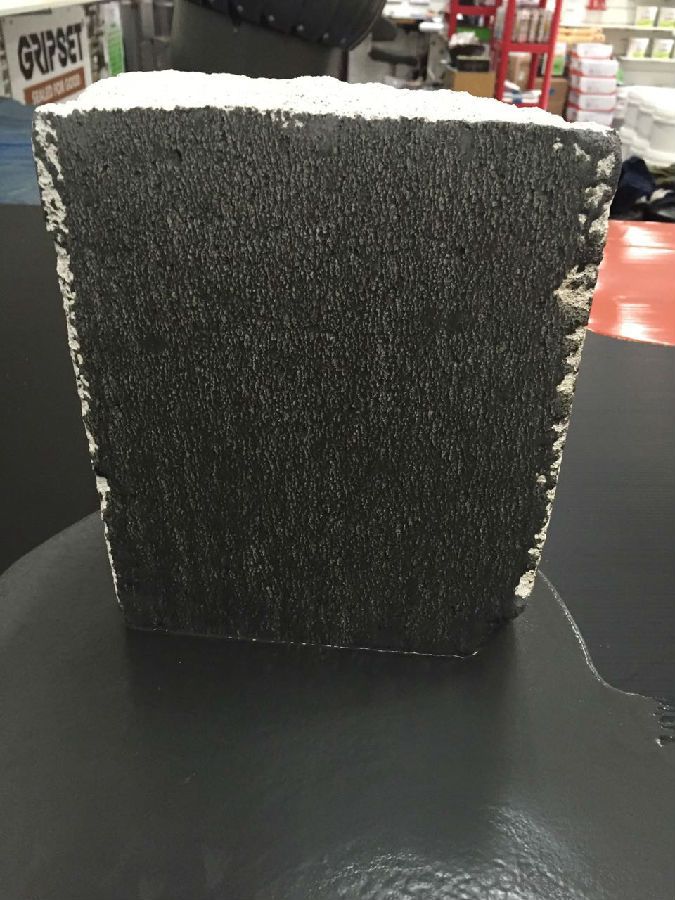

Single Component Polyurethane Waterproof Coating photos

FAQ

1. Which payment do you accept?

For you convenience, our payment can be L/C, TT

2. Is free sample available?

We can supply free samples. You'll just need to pay for express cost.

3. How about your quality?

We have strict quality control system, we make testing on incoming raw material and finished products. Your third party testing is also welcomed. With high quality, our products are used on government projects at home and abroad. Our product quality is accepted by clients from all over the world. Warmly welcome your samples requirement or trail order.

- Q:Self-built concrete house finished three years after the use of large-scale housing wall leakage how to do?

- Second, the chisel in addition to the wall structure to the wall structure for waterproof construction, you can use the material coating, membrane and infiltration of crystallization, the quality is different.

- Q:Roof membrane waterproof construction process, what should be noted that?

- Coil ply attention Paving direction, slope less than 3%, parallel and roof paving, slope greater than 15% or roof vibration, perpendicular to the roof paving. Slope between 3% to 15%, can be parallel to the vertical; membrane waterproof roof slope should not be greater than 25%. The upper and lower layers may not be piled on each other.

- Q:Rigid (concrete) waterproof roofing shop SBS coil can brush a layer of waterproof paint before?

- Second, the completion of the construction of the membrane and the acceptance of qualified, should do the protection of finished products, it is recommended to use cement mortar to do protective layer, construction should pay attention to the surface should be smooth pressure, and set the surface sub-grid, 1 m2. If the use of block material to do the protective layer, the sub-grid area should not be greater than 100 square meters, sub-grid width should not be less than 20mm; if the use of fine stone concrete protective layer, the sub-grid area should not be greater than 36 square meters. Note: Regardless of which protective layer is used, a separation layer should be provided between the waterproofing layer and the protective layer.

- Q:Why should the use of high pressure perfusion waterproof plugging method

- High pressure grouting construction principle: is a special high-pressure grouting waterproof material through the high-pressure infusion equipment into the concrete crack structure extended until all the cracks (including the naked eye is difficult to meet) filled with water (water) with the cross-linking reaction, Release a large number of carbon dioxide gas, resulting in secondary pressure, high pressure and secondary pressure will be pressed into the elastomer and filled with all the gaps, to stop the purpose of leakage, it can be said that the best performance of plugging material,

- Q:Roof for the insulation, Master roof, using two waterproof construction program

- Third, security measures 1, firmly establish the "safety first, prevention first" safety production policy. Before the operation, the site management personnel must be to the operation team to carry out security technology to the end, and actively carry out pre-class security activities, security personnel check, supervise. 2, the roof around the poles outside the scaffolding (protective railings), roof construction is strictly prohibited removal. 3, roof construction, debris and other materials is strictly prohibited from the roof directly down throwing. 4, storage of coils and adhesives warehouse or site to prohibit the fireworks, for the use of fire, there must be fire prevention measures, and should set a certain number of fire extinguishers and sand bags. 5, oil drums should be flat, not two carrying, in the transport process, pay attention to balance, the spirit to focus, to prevent accidental fall caused harm. 6, transported to the roof of the material, should be scattered on average, with the use of transport, not concentrated stacking. 7, the use of torch, you should clear the surrounding flammable items, must be away from the base of oil, is strictly prohibited in the brush base oil area using the torch. Torch petrol should not be over full, cheer should not be too much, in the fire site must be equipped with fire equipment.

- Q:Waterproof material water leakage construction should pay attention to what

- 2, wall treatment · Wall treatment to do about 300mm high waterproof coating, to prevent water infiltration wall back tide. · Bathroom between the wall and the ground (plane and elevation) brushing height should be greater than 100mm. · The height of the shower room in the bathroom is not less than 1800mm. · If there is a bathtub, the height of the wall adjacent to the bathtub should be 300mm higher than that of the bathtub. · Waterproof height of tub is not less than 800mm. · The height of the squat should be more than 900mm. For the transformation of the toilet wall and self-built light wall, the proposed height of the waterproof to do the top.

- Q:There is no formaldehyde in the finished putty

- Visible putty powder and formaldehyde or a great relationship, but now many manufacturers have introduced environmentally friendly putty powder, not only environmentally friendly pollution-free important is also can control the air, there is a negative ion putty powder is the composition which contains tourmaline tourmaline, through And the water molecules in the air combined with the decomposition of negative ions to deal with the air, anion can be neutralized with formaldehyde into dust falling into the air, you can also remove the dust in the air, as well as enhance the metabolism of the function.

- Q:What are the materials used in the ceiling?

- Kitchen bathroom ceiling material 3: waterproof gypsum board ????Waterproof gypsum board is in the gypsum core by adding a certain amount of waterproof plastic made of products, so waterproof gypsum board has a certain waterproof function, while gypsum board paper is also a waterproof measures, is a more widely used materials. Waterproof gypsum board with the effect of thermal insulation, but also has the advantages of fire, noise, but also an easy decoration materials. There is also a feature of the characteristics of environmental protection, due to the use of natural gypsum as a raw material, in the home environmental protection is guaranteed.

- Q:What is the difference between finished mortar and cement mortar?

- Finished mortar for dry areas, because the addition of lime, lime water retention is good; cement mortar for wet areas, because the high strength.

- Q:How to do waterproof bathroom, construction process is what

- 4, closed water test. Closed water test, the highest point of the ground water can not be less than 2 cm, save at least 24 hours, observe the phenomenon of no leakage after the operator. If there is leakage, need to redo, and can not neglect.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Waterproof Coating For Roof Single Component Polyurethane

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 1000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords