Waterproof and Fireproof PVC Ceiling Panel PVC Wall Panel,PVC Panel

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1,Structure of (PVC Ceiling ) Description

Size: 600 X 600mm

Material: PVC

Stylish architectural decorative products

Available color: solid color, two-tone color, metallic color.

2,Main Features of the (PVC Ceiling )

Main introduction of PVC Ceiling Panels

1.Thickness:5-12MM

2.Width:100-300MM

3.Length:It depends,like 5.8M,5.95M matching with the size of containers.

4.Type: Flat or with a groove in the middle of panels.

5.Contents of PVC panels: normal & popular PVC percentage is 40%, 45%, 50%, 55% or 60%, balance is calcium carbide or other carbonate.

6.Surface treatment:

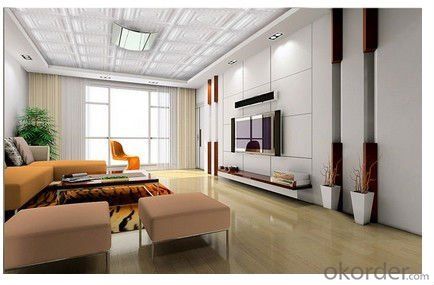

3,(PVC Ceiling ) Images

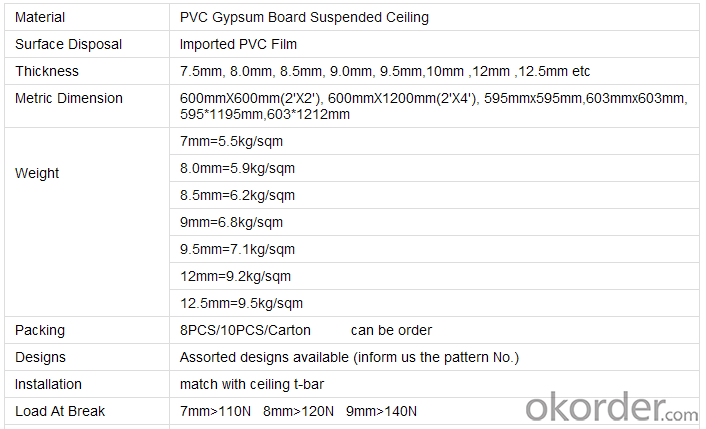

4,(PVC Ceiling ) Specification

5,FAQ of (PVC Ceiling )

Directly mounted on ceiling by glue-up.

Easy to install, easy to clean, stain and water resistant, resource friendly.

Perfectly conceal all ceiling defects.

Available in a variety of colors - white, black, gold, silver, antique gold, antique brass, .... etc.

Custom colors available on special order.

- Q:Will pvc floor is how to make out, it is best to specific? Thank you!

- More is the wood-plastic foam board is nothing more than resin powder, wood powder, hard calcium, stabilizer and other small material mixed extrusion

- Q:How much is it?

- There is a good difference between the price is different, to see what you want

- Q:Chevrolet board and wood-plastic plate difference

- Chevrolet board, also known as PVC foam board, the main material for the PVC, PVC is made through the extrusion after extrusion molding equipment. In order to increase its performance often add antioxidants, flame retardants and so on. PVC wood-plastic plate, the main material for the PVC and wood flour, and PVC foam board production process is basically the same, but in the production process to control the degree of foam, and fully mixed with wood flour. In order to increase its performance, also need to add antioxidants, flame retardants and so on. The difference between the two, mainly reflected in the production of different raw materials. Chevron board is also known as PVC foam board (PVCexpansionsheet) and Andy board. To polyvinyl chloride as the main raw material, adding foaming agent, flame retardant, anti-aging agent, the use of special equipment extrusion molding. Common colors are white and black. Chevrolet board can be comparable with the wood, and can be sawing, planing, can be nailed, sticky, but also has no deformation without cracking without painting (a variety of colors) and other special features; and low foam sheet can be welded, Ink printing and can also be used saw, drill, milling and other methods for machining.

- Q:PVC board surface a lot of white spots, what is the reason?

- I do not know what you use the material, if the use of PVC resin (not renewable material), then select a reasonable resin model, the formula should be reasonable, screw temperature, die temperature, calendering roller temperature (three rollers), raw materials must Control, drying is also critical.

- Q:PVC plastic hard board maximum temperature how much

- More than 70 degrees will be deformed, more than 130 degrees will begin to melt ~!

- Q:What is the PVC board and KT board, what are the specific role?

- PVC board is PVC as raw material made of cross-section for the honeycomb mesh structure of the plate. Is a vacuum plastic film, used for all kinds of panel surface packaging, it is also known as decorative film, with film, used in building materials, packaging, medicine and many other industries. Which accounted for the largest proportion of building materials industry, 60%, followed by the packaging industry, there are several other small-scale application of the industry. According to the degree of soft and hard can be divided into soft PVC and hard PVC. According to the production process can be divided into PVC crust foam board and PVC free foam board.

- Q:Hollow engraved high density board and PVC which is good

- Hollow carved high-density board and PVC that good this problem, in fact, see how much you do, if the wet, then try to do PVC, MDF is generally no problem. The material of this plate is made with the size of the partition you made, like the partition of the PVC board is not suitable for large carved, PVC board has a certain wayward, but the quality easily damaged. MDF is the plant fiber by breaking, the application of adhesive through the high temperature and pressure environment made of sheet metal.

- Q:How can PVC board be bonded together

- There is a dedicated PVC adhesive.

- Q:Pvc board ceiling each piece of zero sale!

- This difference is very large, the worst eight dollars three meters, the best of the dozens. The price of the region will be different.

- Q:We had a plumber come to unclog our drain on our tub. He never looked at the pipes that we had or anything. He just walked in started up his electric snake and immediately busted our pipe causing at least $10,000 worth of damage to our living room ceiling and floor.He is now trying to say that it wasn't his fault because we had the wrong kind of pipe and it was brittle.After talking to some general contractors, my thinking is that he used the wrong tool for the job and did not use reasonable skill and care. Of course the pipe looks brittle after your machine busted it!I fear we have a battle ahead. Looking for some good information.

- Generally speaking yes it is ok to do this but some sort of survey should have taken place prior to its use. This should establish the condition of the pipework as older pvc pipes will degrade in sunlight particularly and go brittle.Obviously I am unable to comment on the wrong type of pipe as I dont know what pipe this is but I think its age is more likely to be the main problem not its type.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Waterproof and Fireproof PVC Ceiling Panel PVC Wall Panel,PVC Panel

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords