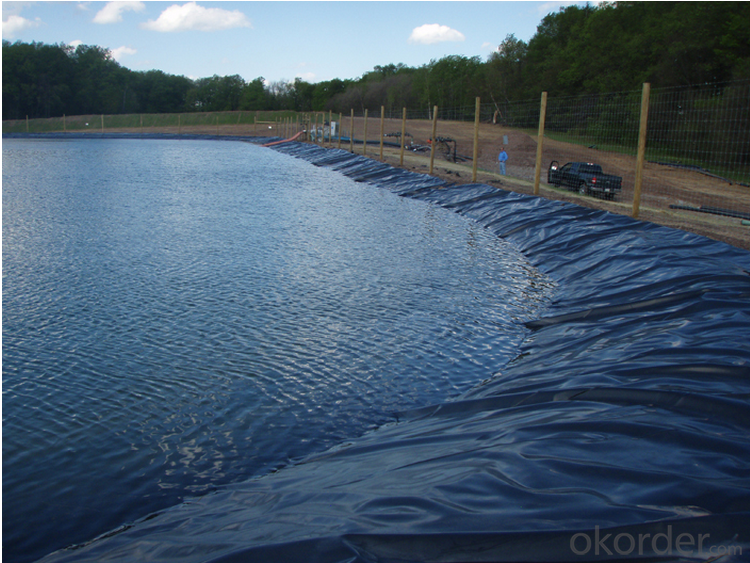

water proof and breathable geomembrane

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 900000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Characteristic

1.Good mechanical properties, high tear strength, deformation and adaptable, puncture resistance, anti-aging, anti-ultraviolet-resistant, Anti oil and salt, pH, anti-corrosion, high temperature-resistant, non-toxic, long service life.

2.Water, drainage, seepage, the good effect of moisture, width, thickness of the full range of specifications and low cost, simple construction.

Applicable scope

1) Environmental protection, sanitation (such as solid waste landfills, sewage treatment plants, power plants Chi-conditioning, industrial, hospital solid waste, etc.) .

2) Water (such as rivers, lakes and reservoirs of the anti- dam, plugging, reinforcement of the canal seepage, the vertical wall of the heart, slope protection, etc

3) Municipal Engineering (subway, on the ground floor of the building, planted roof, the roof garden of anti-seepage, sewage pipes lining, etc.).

4) Petrochemical (chemical plants, oil refineries, gas storage tanks of the anti-chemical reaction tanks, sedimentation tanks of the lining, etc.).

Project | Index | |||

GL | GH | |||

GL-1 | GL-2 | GH-1 | GH-2 | |

Tensile strength (MPa) | ≥14 | ≥17 | ≥14 | |

Break elongation (%) | ≥400 | ≥450 | ≥400 | |

Right angle tear strength (N/mm) | ≥50 | ≥80 | ≥50 | |

Carbon black content (%) | ≥2 | |||

Water vapor permeability coefficient (g.cm/(cm.s.Pa) | ≤1.0x10-12 | |||

-70 Low temperature brittleness properties | pass | |||

Dimensional stability (%) | ±3 | |||

FAQ

How about the delivery time?Lead time since receipt of 30% T/T deposit payment: 3 weeks.(Samples will be prepared within 3 days.)

2.What's are the MOQ?Generally speaking, the MOQ is one container, but we can provide you samples for quality inspection.

3. Do you charge for the samples?Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

4. Can you produce according to customers' design?Sure, we are professional manufacturer, OEM and ODM are both welcome.

- Q:Does computer monitor need to stick screen protecting film?

- No, it is ridiculous to say that the film is radiation?protection. What film can prevent light radiation? Unless the lead metal. What do you still look at? Ordinary film not only can not reduce radiation, instead, the film itself is plastic synthetic product which is radioactive. General film is mainly used for protecting the screen, preventing scratches and dust, but affecting the appearance. And now there are many hard screen which is not necessary to stick film. You can check your screen to see whether it is hard or soft, namely is there water wave when you pressing the screen, if there is water wave, it is soft, which can either stick film or not, but the hard screen is not necessary to stick film.

- Q:What are the functions of computer anti-spy protective film?

- The functions of computer anti-spying protective film: Using special ultramicro shutter optical technology to enable only the users facing the screen to clearly see the contents on the screen, preventing others from spying from two sides of the computer.

- Q:Are geomembranes suitable for use in reservoirs?

- Yes, geomembranes are suitable for use in reservoirs. They are often used as liners or covers in reservoirs to prevent seepage and contamination, ensuring the integrity and durability of the reservoir structure. Geomembranes offer excellent impermeability, chemical resistance, and long-term performance, making them an effective solution for maintaining water quality and minimizing water loss in reservoirs.

- Q:What are the different types of geomembranes?

- There are several different types of geomembranes, including high-density polyethylene (HDPE), low-density polyethylene (LDPE), linear low-density polyethylene (LLDPE), polyvinyl chloride (PVC), ethylene propylene diene monomer (EPDM), and chlorosulfonated polyethylene (CSPE).

- Q:Is good to stick the mobile phone film

- And according to the professional ophthalmologist, although the brightness of the mobile phone screen itself is enough, the display effect is affected after pasting the film on the screen, and the film itself will also have greater wear after a long-term use which further affect the display effect. They will aggravate the visual fatigue of the users for staring at mobile phone screen in a long time, which will damage the user's vision.

- Q:What are the limitations of geomembranes in high-velocity flow conditions?

- One limitation of geomembranes in high-velocity flow conditions is their susceptibility to damage or tearing. The force of the flowing water can exert significant pressure on the geomembrane, leading to punctures or tears if not properly designed or installed. Additionally, geomembranes may experience displacement or uplift due to the high velocity flow, compromising their effectiveness in containing fluids or preventing seepage. Overall, geomembranes may not provide adequate protection or containment in extreme high-velocity flow situations.

- Q:How do geomembranes contribute to the preservation of water resources?

- Geomembranes contribute to the preservation of water resources by providing an effective barrier that helps prevent contamination, leakage, and seepage of liquids, thus safeguarding water quality. They are widely used in various applications such as lining of reservoirs, ponds, and landfills, as well as in wastewater treatment facilities, ensuring the protection and conservation of valuable water supplies.

- Q:How to remove the casings lamination of laptop?

- First shut down the computer. Cut off the electricity as well.

- Q:What kind of membrane should be coated on optical coating glass?

- There are many optical coating for glass. In general, from material, they can be divided into dielectric film and metal film. From performance, they can be divided into antireflection film, reflecting coating, beam splitting film, polarizing film and protective?film.

- Q:How to lap geomembrane?

- filament geotextile, the lap joint of film should be more than 10cm, the destroyed place should be repaired with welding gun. it's materials include HDPE geomembrane, short fiber geotextile is thick or thin, the lap joint of geomembrane is welded with special welder.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

water proof and breathable geomembrane

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 900000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords