Waste Sewage Water Pump Stainless Steel Sewage Pump

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Waste Sewage Water Pump Stainless Steel Sewage Pump

Company Introduce

My company has more than 40 years history, is the China general machinery pump industry association member units.

My company has organized product research and development team, experienced high, intermediate technical staff.

Complete production and processing, inspection, testing (pump performance test platform), and other equipment, to ensure that product quality is stable and reliable.

Over the department, provincial, municipal and industry product quality supervision and inspection (smoke), only one is qualified to go through.Timely quality perfect after-sales service in place, favored by the majority of new and old customers rely on and praise.

My company has successfully passed the national industrial products production license, ISO9001 quality system review replacement work.

Relevant product standards (enterprise), metrology, standardization management system, etc.,

have been acceptance by the superior department in charge of the inspection.Related to product development, production management, sales and aftersales service, are performed according to the system management standard.

Application

This series pump is widely used for sewage treatment of city construction discharge for architecture projects, hotel, mine, pond, dyeing and printing, paper making and textile industries.

It is the ideal tool for transportation of sludge, slurry, living sewage, feces and stale wastes, solid grains fiber, paper chips, sandy soil etc.

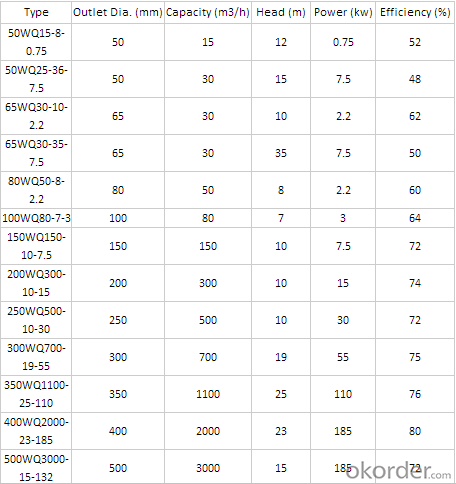

Model Description

100 WQ 50-30-3

100: Drain aperture (mm)

WQ: Submersible sewage pump

50: Capacity (m3/hr)

30: Head (m)

3: Power (kW)

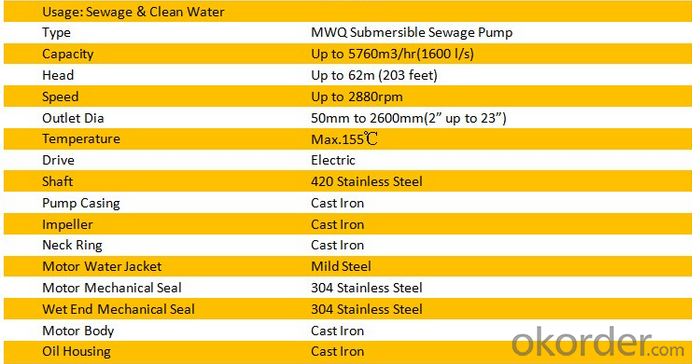

Operations Conditions

1. The medium temperature should not be over 60oC, the density 1200Kg/m3, and the pH value within 5-9.

2. During running, the pump must not be lower than the permitted lowest liquid level.

3. Rated voltage 380 V, rated frequency 50 Hz. The motor can run successfully, only under the condition the deviations of both rated voltage and frequency are not over ± 5%.

4. The maximum diameter of the solid grain going through the pump has not to be larger than 50% of that of the pump outlet.

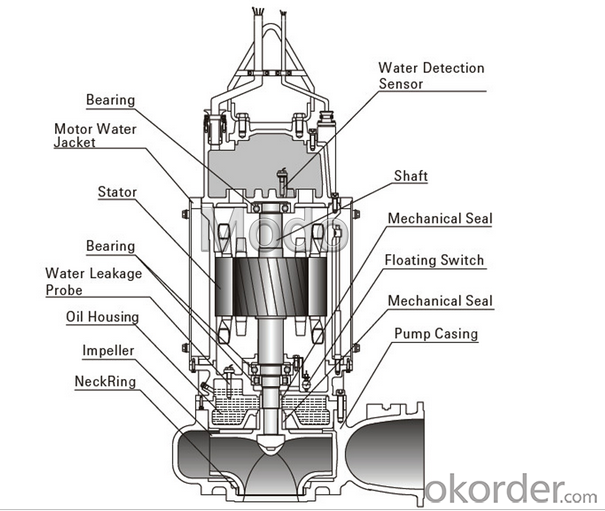

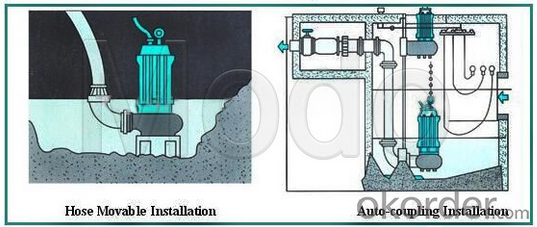

Pictures Show

Trading market

Transportation

- Q:Fire hydrant and fire pump adapter difference

- 1, fire hydrant is generally divided into three types, one is indoor, one is outside, is a municipal, the three has two basic purposes, which is directly connected to the fire hose or fire-fighting water, is the scene of the fire truck with water.2, fire pump adapter from the purpose, for fire hydrant system, automatic spray (spray, Yu Lin) system, divided up from the form, have walls, underground, ground type, its basic purpose is, after the fire, if the fire hydrant system (for example network system) when the water pressure is insufficient or anhydrous (water pump system damage and other reasons), through the pump adapter, the fire water supply to the system or booster.

- Q:Any ideas on where and what type of water pump I should use for my 29 Gallon BioCube tank? It seems that the water pump is very loud and is not working the way it should. There are bubbles shooting the aquarium and I have tried everything to fix it. I am thinking of replacing the water pump all together. Any ideas on brands that would be compatible? Anyone else tried this? Please help...

- ok before replacing have you cleaned the inside, and if there are air bubbles comming out it is because it is running dry. Basically all biocubes do this, the filter pad is slowing down the water too much, so either rince it well or replace it. Also i would wash out the blue sponge right before the pump as that can hold alot of dirt as well. Then if not add more water. But if you want to replace the pump, try via aqua water pumps. they tend to be the best. owner of the BC 29 and BC 14

- Q:I put the new water pump in and the metal tube that goes to the heater hose it is hitting the wheel that holds the 3 belts that goes onto the water pump. why is it doing that. got the right pump. I have a 1986 firebird V6. any ideas?

- It is either configured wrong, (or wrong part number form the factory) or you are putting the pulleys on wrong. You may have left a spacer off, or one or more pulleys is installed backwards or in the wrong order. Make sure the one you have is for the exact engine and options that you have. There are differences for having A/C or not, and other things. Go to a different auto parts store, and compare water pumps from a different supplier. Sometimes they make mistakes when they assemble them, sometimes they assign the wrong part number to them, and sometimes some customer buys one and returns another.

- Q:can this happen that pump is pressurizing system and no flow in suction.

- the answer is YES..but NOT from the PUMP..the type of pump most people have requires that flow through the impeller be available at all times or two things will happen !. it will cavitate (that's a gurgling sound at the pump) or 2. It will only beat the water that is in the pump and no flow will be apparent. Either one of these though could be a symptom of a plugged hot water line in the loop. Here is what happens to increase the pressure apparent.. The water on the loop is pressurized from the storage tank to the pump then out to the loop .If the loop is terminated and air gets into the end of the line next to the restriction the outside water pressure is acting like a piston compressing the air that air reacts the same as it would in any compressor and can reach higher than normal operating conditions. If you will find the plug and install an expansion bladder in the highest part of your line your flow ,pressure and noise problems will stop...Good luck with the search...From the E

- Q:Im replacing the water pump in my 1992 toyota celica, and i cant get the pully off! i have been working hard for like an hour, i took the belts off. all i have is good old fashoned sockets and crescent wrenches. do i need to get the pully off? and is it lefty loosey and righty tighty or righty loosy lefty tighty?? because sometimes i hear they reverse it. thanks- jordan

- I am sure you would have to get the pulley off in order to access the bolts holding the water pump on. Is there not 4 bolts holding the pulley on? I agree with Don below here. My experience with toyota water pumps was with my 1986 toyota pickup where the pulley did come off after removing the fan.

- Q:Pump performance parameters have three sets of data, how to understand the flow, lift, flow speed

- Mainly expressed the ability of the pump, mainly as a basis for selecting the pump users.Lift represents the performance of the pump to boost water pressure. Such as the pump head H=38 meters, that the pump outlet pressure normal to 0.38MPa.The flow rate represents the water supply capacity of the pump. Such as 100 m3/h. The general flow pump design, and the corresponding flow, little significance.

- Q:Why does the pump decay when connected in parallel?

- Because a water pump has reached the rated parameters, the parallel is only "superfluous".

- Q:i have a significant stream of water running out of the coolant return side of the engine under the coolant pipe on a 1997 caravan i will lose a gallon and then it stops until the engine heats up and of course more comes out with expansion

- oh boy i think u have to take the timing belt , matterof factchange the timming belt too , it should be cheaper since it's already open,check pepboys autozone,murray's , they would give u a diagram for it

- Q:i have an underground water tank, my jet pump went out again, got a new one, waiting for the guy to come install it. i got an old fashioned iron hand pump, for when the electric, or the pump goes out again, i can pump out water. got pipes, fittings, foot valve. i just dont know what kind of base to make ,to bolt pump to, over the pipe that will come out of the ground. any ideas?

- you can make a wooden floor cover using a treated good lumber of 1 X 6 for the floor and 2 X 6 lumber for the floor joist. assemble the 2X6 lumber for the floor joist. depending on the top area of your water tank. arrange the floor joist at 0.60 meter spacing and 1.2 meter braces. after that, use 1X6 lumber as flooring with at least 2 cm spacing between lumber. as on the base of your pump, you can reinforce it by adding 2X6 braces. use a lug bolt depending on the size of the slot at the base of your pump then bolt it on top of the 1X6 flooring. its better if we can draw it here to make it easier to understand and explain i dont know if this can help much because we havent seen the actual situation of your tank and your pump.

- Q:My water pump is sitting very close if not rubbing against the case. There were shavings and a groove. Would this cause it to knock? Also would this blow up the lower end? One more, Should it be in the center or offset twards the top?

- it won't spin whilst you evaluate that's quickly geared to the crankshaft. turn the crankshaft - it is going to then spin. you may no longer eliminate the water pump without eliminating the grab conceal. eliminate the water pump shaft's protecting clip, to eliminate the water pump.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Waste Sewage Water Pump Stainless Steel Sewage Pump

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords