Warp Knitted Polyester Geogrid with CE certificate for Road construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30000 g/m²

- Supply Capability:

- 600000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Warp Knitted Polyester Geogrid Description:

Polyester geogrd applies chemical fiber with extreme strong elasticity modulus,make it into grid loom stare through oriented warp knitting ,then ater coating the geogrid is formed with the name of "fiber soft steel".

Main Features of Warp Knitted Polyester Geogrid:

Polyester geogrid has high tensile strength and high tear-resisitant

Compared with the traditional road surface, it reduces the cost, prolong the service life, and avoid the reflection road crackle.

Polyester geogrid is also used to strengthen the soft land, such as railway, airport, irrigation work, and dyke, etc, and the roadbed

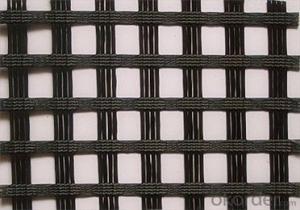

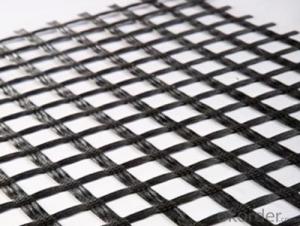

Warp Knitted Polyester Geogrid Images

Warp Knitted Polyester Geogrid Specification:

Item | Art.No. | PLB010101 | PLB010102 | PLB010103 | PLB010104 | PLB010105 |

Specs | TGDG25 | TGDG35 | TGDG50 | TGDG80 | TGDG110 | |

Unit weight,g/m2 | 370±50 | 450±50 | 550±50 | 700±50 | 1100±50 | |

Width,m | 1.0+0.2/-0 or 2.0+0.2/-0 | |||||

Tensile strength, kN/m≥ | 25 | 35 | 50 | 80 | 110 | |

Elongation,%≤ | 10 | |||||

Tensile strength at 2% strain,kN/m≥ | 7 | 10 | 12 | 26 | 32 | |

Tensile strength at 5% strain,kN/m≥ | 14 | 20 | 28 | 48 | 64 | |

Roll length,m | 50+0.25/-0 | |||||

FAQ

We have organized several common questions for our clients,may help you sincerely:

Q1: How about your company?

A1:Our company are one of the largest geosynthetic products supplier in the world.We have the products experience more than 20 years.Already export to USA/Germeny/Australia/Zambia/Brazil etc.more than 20 countries.Almost 10years.Our products including Geocell/Fiberglass Geogrid/Geomembrane/Geotextile/Geonet etc.

Q2.Does your products have good qualitity?

A2:Yes,we have do many big projects such as the 2008 Beijing Olympic BIRD NEST. Divert water from the south to the north project. And our products have CE certificate also.

Q3:How long can we receive the products after purchase?

A3:In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 15-20 working days can be delivery.

- Q:Do geogrids provide reinforcement to geosynthetic clay liners?

- Yes, geogrids can provide reinforcement to geosynthetic clay liners. Geogrids are typically used in combination with geosynthetic clay liners to improve their tensile strength and overall performance. The geogrids help distribute loads and restrain the movement of the clay liners, enhancing their stability and reinforcement capabilities.

- Q:How much is the tensile strength of geogrid???????

- Whole plastic stretch type: two-way products: 15KN--50KN one-way products: 50KN---300KN

- Q:Glass fiber grille material.

- In order to protect the glass fiber, improve the overall performance of the use of special coating treatment process of the composite materials.

- Q:Is the test items within the inspection listAcceptance specification

- Lower bearing layer smoothness

- Q:Can geogrids be used in reinforcement of tunnels and underground excavations?

- Yes, geogrids can be used in the reinforcement of tunnels and underground excavations. Geogrids are often installed to provide additional support and stability to the surrounding soil or rock mass, reducing the risk of collapse or deformation. They can help distribute the applied loads and increase the overall strength of the structure, making them a suitable choice for reinforcing tunnels and underground excavations.

- Q:Glass fiber mesh and geogrid which is good

- There are many types of geogrid, glass fiber geogrid is only one kind of geogrid, geogrid also includes polyester grille, steel plastic grille, plastic grille, etc.!

- Q:How are geogrids installed in construction projects?

- Geogrids are typically installed in construction projects by first clearing and preparing the site, followed by laying a layer of geotextile fabric over the prepared area. The geogrid is then unrolled and placed on top of the fabric, ensuring proper alignment and overlap. The edges of the geogrid are secured using pins or stakes. Finally, the geogrid is covered with additional layers of soil, aggregate, or asphalt, depending on the specific project requirements.

- Q:What does the geotextile 200# mean?

- 200 grams, the unit is g/ square meters per square metre, representing the weight of Geotextiles

- Q:Can geogrids be used in ground improvement techniques?

- Yes, geogrids can be used in ground improvement techniques. Geogrids are commonly employed to reinforce and stabilize weak soils, enhance load-bearing capacity, and control soil erosion. They are effective in various ground improvement applications such as retaining walls, slope stabilization, and road construction. Geogrids provide increased tensile strength and distribute loads, resulting in improved stability and performance of the ground.

- Q:Geogrid manufacturers and the price is how much?

- Product features: uniaxial geogrid is a kind of polymer as the main raw material, adding anti UV, anti aging agent must, after the original tensile distribution chain shaped molecules scattered re aligned linear, pressure into a sheet by extrusion and punching network rules, high strength and geotextile material the longitudinal stretch into the.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Warp Knitted Polyester Geogrid with CE certificate for Road construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30000 g/m²

- Supply Capability:

- 600000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords