Wanfeng Tower Crane

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 35 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Weihai Wanfeng Group is located in Manshan Town, Weihai City-Model Town of National Small Town Construction, where

traffic is convenient and industry is developed.

Weihai Wanfeng Group, originally founded in 1995, is one of the first enterprises that restructured in Wendeng City

in 1997. The present group company was founded in 2003 and composed of four companies-Wanfeng Steel Structure, Wanfeng

Door & Window, Wanfeng Leasing and Yifeng Properties. It has 400 staff, fixed assets of about RMB70 million and land

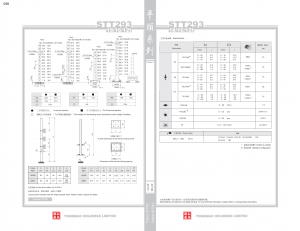

area of 90,000m2. Main products include FO/23B, 7030, QTZ125, QTZ80, QTZ63, QTZ40 and QTZ315 series tower crane,

construction lifts and material elevator, as well as construction steel structure and high-grade aluminum-plastic doors

and windows. Its products are sold in more than 10 provinces and cities in China and over 20 foreign countries.

Weihai Wanfeng Group is Top 10 Tower Crane Enterprises of Shandong Province, Top 100 Private Enterprises of Weihai

City, Top 20 Enterprises of Wendeng City, "AAA" Level Banking Credit Enterprise, Provincial-level Advanced Equipment

Management Unit, Provincial-level "Contract Honored and Promise Kept" Unit and Top 100 Provincial-level Honest

Enterprises. "Wanfeng" trademark was rated as Shandong Famous Brand, and Wanfeng tower crane is honored Shandong Brand-

name Product.

Weihai Wanfeng Group has always been adhering to the business tenet of "quality first, credit first", regarding

customers as God and workers as source of development, paying attention to technology development, service and product

quality, introducing and innovating brand products, and injecting endless vigor and vitality to the company development.

Weihai Wanfeng Group has strong technical force and excellent testing equipment. In 2001 it passed IS09001: 2000

Quality Management System Certification, and enhanced both management and service quality. With China's entry into WTO,

Wanfeng Group keeps an eye on the world development and continuously expands foreign markets. In 2004, its products

entered the international market, in 2006 took the lead to achieve license to enter the Russian market, and in 2007

passed CE certification and opened the door to the EU market, winning favorable opportunity for construction in foreign

market. With good reputation and services, our products attracted are more and more foreign customers.

After nearly 10 years of development, Wanfeng Group has developed into an enterprise engaged in multi industries-

construction machinery, construction steel structure, building doors and windows, and real estate. The opening Wanfeng

Group always marches ahead.

Mr. Ma Shangquan, chairman of Wanfeng Group, said, "We serve your need, and promise to meet your satisfaction", and

welcomes cooperation with old and new customers to expand business opportunities and seek common development.

The developing Wanfeng Group will continue to innovate and take part in market competition both at home and abroad

with confidence and determination, produce newer and better products based on self-encouragement and strict management,

and strive in the new century future development to accept the challenge.

- Q:i probably sound like an idiot asking this question :Pis it electricity? fossil fuel burning involved? pulleys? how does the pulley work? any human power involved? specifically, how is it stupid to lift a chair that can be lifted by a person, with a crane?

- Most cranes are diesel engine powered hydraulics and hydraulic motor. So that would be fossil fuel. Some cranes use pulleys to magnify the total lifting capacity. A pulley magnifies work by exchanging distance for lifting power. For example, to lift a 10 ton weight 20 feet in the air, if you put four pulleys in there so that 80 feet of cable would have to be pulled up , then it would only take 1/4 the amount of power to lift that 10 tons (2.5 ton lifting force would lift it) Look at any links or wikipedia for how compound pulleys work.

- Q:Who thinks William Shatner is adorable as Denny in Boston Legal? I do!! I just want to pinch his cheeks. He looks so lovable (in a chubby old guy kind of way. Lol.)AhahaAnd Shirley. She's so funny.Lincoln, suck. my. lobe. lol!Anywho...answer my denny question!!

- He is so adorable, I love when he was sleeping with the munchkin lady! Also Betty White is hilarious on that show.

- Q:I've only seen one book that has it.I can't buy it until I get more money.That's the only one from that book I really wanted though...Is there any site that has it?With a diagram.Thanks!

- Now, If the guy was 75 yrs old, with beautifull gray hair and can ballroom dance, and asked If he could kiss me , I would say yes, The one thing I hate is when a guy opens his mouth over yours and thinks thats a kiss, I would have to tell him I don't need a bath. Or that I don't need to be swallowed up. If he's that hundgry he should go get something to eat at A fast food place. HA HA HA.

- Q:In the U.S. please and tell me where and how you got the number.Thanks!!!

- There are so many overhead cranes in operation today in the US and around the world. They could be numbering in tens of thousands in industries and other operations. An overhead crane, commonly called a bridge crane, is a type of crane found in industrial environments. An overhead crane consists of parallel runways with a traveling bridge spanning the gap. A hoist, the lifting component of a crane, travels along the bridge. If the bridge is rigidly supported on two or more legs running on a fixed rail at ground level, the crane is called a gantry crane (USA, ASME B30 series) or a goliath crane (UK, BS 466). Unlike mobile or construction cranes, overhead cranes are typically used for either manufacturing or maintenance applications, where efficiency or downtime are critical factors. Have a pleasant day.

- Q:What kind of flower is the Sunset Crane?

- Okay, i'm going to get every backyard gardener east of denver jumping down my throat on this one, but it's time you all wake up and know the real name of one of your favorate potted plants. only then will you beleave me when i tell you the sunset crane is a type of geranium. the true geranium. not the plant most people know as the geranium is botanically Pelargonium. that silly looking, red flowered, fuzzy leafed thing everyone loves to stick in a pot by their front door every summer back east and mistakenly call a geranium is not really a geranium. even the fancy Martha Washington geranium is not a geranium. it is the Martha Washington Pelargonium. but whats the use? unless you are a botanist everybody back east is going to say i'm just another fruit cake from california. (born and raised in wisconsin i'd like to add) okay, your sunset crane is botanically a geranium, often called by it's common name cranesbill. okay, you have the real best answer, so go ahead and pick the wrong best answer from some smuck from back east who knows best. sure i have two post graduate degrees in science, been a univ certified master gardener for over 15 years and just might know a tad bit more then the eastern fair weather, summer time gardener. but don't let that prevent you from thinking i'm nuts and choosing a better, best answer. i'm used to it. grandma is always right... until her plant dies. then they call me for the real low down.

- Q:im 35 and in august i get my license back and i am going after my childhood dream of being a crane operator and was wondering how i need to go about achieving this?

- I agree. There are schools (USA) that teach this kind of thing. You attend, receive a diploma attesting to your success then you can approach prospective employers that hire people with these skills. I wish you the best. :)

- Q:Hi there!I was planning on making an electromagnetic crane, and I already understand how the electromagnet works. Its for the science fair in two weeks, but they asked us to make our projects soon.But I not sure hot to build the crane itself, any ideas?

- Here are literally thousands of organized woodworking projects in a members area and all you have to do is get them off your computer any time you want.

- Q:Operation points of tower crane (tower crane)?

- Safe use requires the use of tower crane, issued by the state competent authorities shall abide by the rules and regulations, but also comply with the relevant provisions in the manual: the crane working environment temperature is -20~40 degrees Celsius, the maximum working pressure is 205N/m2, when should stop using the winds of more than 6 level; the same construction site to install more than two sets of tower crane when should pay attention to the location of each tower, take the elevation of different operations, in order to avoid the tower crane jib, balance arm collision accidents; safety device of tower crane, luffing and slewing height, mass and moment limiter, the last two more important, if the two is not detected qualified, will be regarded as the unqualified, because it plays a role to ensure the safety and prevent the tilting of the tower crane. As a construction site, the tower crane torque limiter failure or to replace the operating personnel mistakenly believe that daily only hanging 800-1000kg materials, not what the risk, the results in a process of lifting materials, because of the construction site is narrow, hanging by the operator sight blocked, hanging objects hanging on building the steel frame, caused by tower crane shaking, was the occurrence of major accidents, thanks to the ground work riggers promptly notify the operator immediately stop to avoid rollover accident of tower crane appeared. It is obvious that all safety devices on the tower crane are essential and must be checked regularly to ensure that all the safety devices are in good condition, sensitive and reliable.

- Q:Im hearing this like every day theres more going down..why is it happening? A terrorist plot perhaps? I say we send some troops to stand guard and prevent another tragedy!

- These are dangerous peices of equipment, they endure high stress and are at times pushed to the physical limits. I have on occassion worked with and under them and always had a lot of respect and always felt safer when away from them. Construction cranes in particular are more dangerous because they are forever changing in height,position, amount and type of load. Cranes in permanent installations are ususlly carrying same or similar loads. Construction sites are hazardous due to many factors but just about everything on site gets handled by the crane at one time or another. Inspection,inspection, and re-inspection with concurrent correction/adjustment are the only preventative measure availble beside the assurance of competency of the operator. There are plenty of laws about them already but this is not to say new ones might be justified as new hazards become apparent. Most terrorists are too dumb or lazy to get involved with cranes--why bother when so many easy targets are out there !!!!!!!!

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Wanfeng Tower Crane

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 35 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords