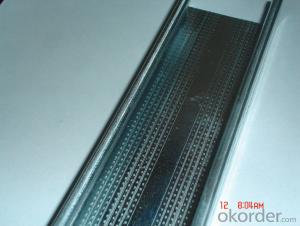

Wall Angles for steel profiles

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications:

1. Material: Galvanized Steel Sheet

2. Items: Crab connector, U-shape, Wall angles and etc.

3. Size: Standard or customized

4. Thickness: Standard or customized

5. Use: For steel profile (ceiling and partition systems)

Feature:

1. Light weight, high strength, safely;

2. High zinc coating, moistureproof, fireproof;

3. Easy and fast for installation, time-saving;

4. Durable, long time life;

5. Recyclable, environment friendly;

6. Can supply products based on specific requirements;

7. Prompt delivery, high quality, competitive price and complete sets of style;

- Q:For example, the original requirement is 0.9 to 1.0 But actually made a 0.7, Is there any harm?

- Should be no difference. I do the aluminum buckle plate, aluminum buckle plate triangular keel and the main keel two Triangle keel is responsible for the fixed buckle, so the spacing is uniform with the buckle plate; The spacing of the main keel is self-regulating, but usually only the spacing is too large to be harmful (unstable). The only difference between the small gap, I think only a waste of material this shortcoming. Mineral wool board and the like should also be the same ceiling, from the security point of view, the appropriate range, the spacing would rather smaller. Do not know what the specific environment you ask, just from the industry point of view to talk with you about

- Q:Will the use of light steel keel and gypsum board ceiling decoration home ceiling, how much money ah?

- Flat top artificial materials 55 yuan a square, the opposite sex 75 to 80 yuan a square

- Q:Master ceiling should choose what specifications of light steel keel

- The main bone C60 is shown on the chart

- Q:Light steel keel ceiling boom and whether the strong electric lines can be common

- Construction regulations are not allowed.

- Q:Light steel keel ceiling hidden information, including what ah

- Keel, hanging bars, other accessories and other quality to meet the design requirements and related norms, to have the relevant certificate and test reports, and a few copies;

- Q:Light steel keel ceiling budget how to calculate

- According to the net area of the room, the light steel keel and the surface layer, if it is flat sets of a ceiling, if there are high and low sets of hanging ceiling, and can calculate the lamp openings and light boxes, of course, there are other art ceiling Construction requirements and quota related provisions apply to the fixed subhead. Light steel keel ceiling, is that we often see the ceiling, especially the shape of the ceiling, are made of light steel keel frame, and then covered with gypsum board made. Light steel keel ceiling according to load is divided into human light steel keel ceiling and not on the light steel keel ceiling. Light steel keel according to keel section can be divided into: U-keel and C-keel. According to specifications can be divided into: D60 series, D50 series, D38 series, D25 series.

- Q:Light steel keel how to do secondary ceiling

- Secondary ceiling local use of wood core board structure, hanging hanging wooden core board structure can do two ceiling. Any light steel keel ceiling of the multi-level ceiling and complex modeling, multi-use wood core board and light steel keel convergence.

- Q:Light steel keel gypsum board ceiling is good, or sauna board, integrated ceiling buckle board good?

- Cost, gypsum board hanging flat top cheap! Performance is the best integrated buckle ceiling! Deformation coefficient is small! But the bedroom is no water! Suggestions or use light steel keel to hang! When loading the lights to hang on the keel! Light steel keel gypsum board ceiling about 70 per square meter it!

- Q:What is the general ceiling of indoor ceiling?

- Now a lot of aluminum buckle board, very cheap, the effect is also good

- Q:What is the light steel keel?

- Light steel (paint) keel, is a new type of building materials, with the development of China's modernization, in recent years has been widely used in hotels, terminals, passenger stations, stations, theaters, shopping malls, factories, office buildings, old Building renovation, interior decoration, roof and other places. Light steel (paint) keel ceiling with light weight, high strength, to adapt to water, shock, dust, noise, sound absorption, constant temperature and other effects, but also has a short duration, easy construction, etc., by the user and the design unit widely used. Light steel keel and paint keel is the difference between the general light steel keel is not painted surface treatment, making coating (galvanized), and paint keel surface made paint, generally divided into black and white, a few according to the design requirements baked into other colors, Mainly because most of the paint keel used in the Ming keel, paint is to ensure that the exposed part of the rust does not affect the appearance.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Wall Angles for steel profiles

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords