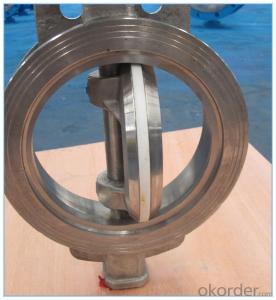

Wafer Type PTFE seated Butterfly Valve with Handle wheel/Lever operation

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 unit

- Supply Capability:

- 2000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Wafer Type PTFE seat Butterfly Valve with Handle wheel/Lever operation

The Butterfly Valve Standard

Designed: API609, ASME B 16.34,AWWA C 504, BS EN593

Face to Face: API 609,AWWAC504, BS2080, and ISO5752

Flange End: ASME B 16.5, ASMEB 16.47, BS EN1092, ISO7005

Inspection Test: API 598, BSEN 12266, ISO 528

Materials Choose

Body Materials:WCB/WCC/LCB/QT450-10/QT500-7/CF8M/CF3M

Disc Materials:WCB/WCC/LCB/QT450-10/QT500-7/CF8M/CF3M

SeatMaterials:304/316/Graphite/Asbetos/PTFE

Specifications

Pressure:PN10/PN16/PN25/CL150/CL300

Size: DN40---DN3200

Drive Mode: Manual/Wormgear/Electric/Pneumatic

Field of Application: Electric/Hydraulic/Municipal Engineering etc; Water/Sea water/Gas etc.

Delivery:

within 15-30days after receipt of at sight L/C or 30% as advance payment by T/T

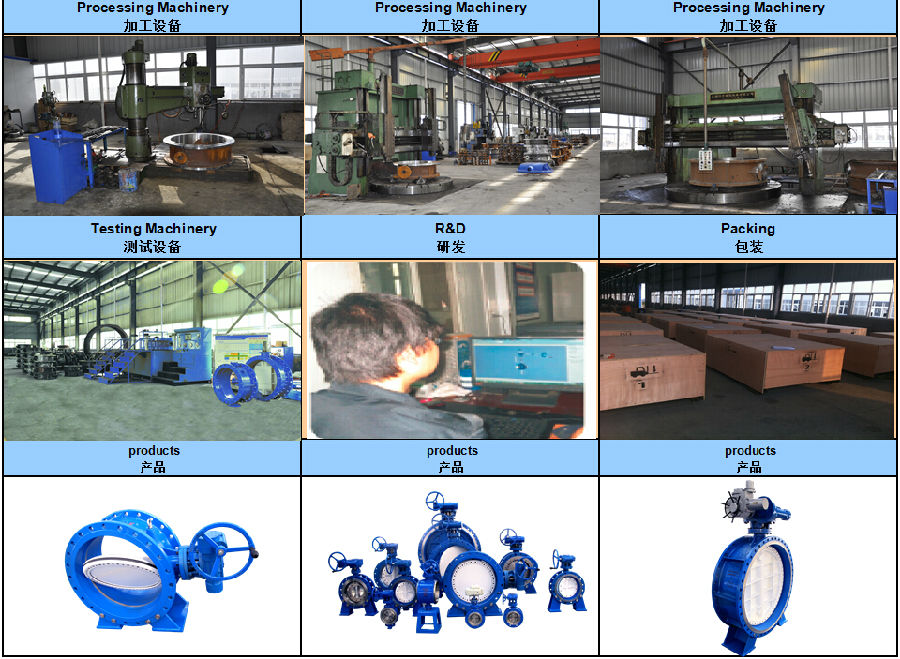

Butterfly Valve Packing: Seaworthy packing:

1. Single Butterfly Valve is packed with foam plastic bag.

2. Put sponge in each floor

3. Electric or pneumatic actors will Individual packaging it with wood box.

4. Export Wooden Packing

5. We can pack according to specific customer requests.

6. Customers’ logos are available on package.

7. Design and manufacturing the wood box to save the sea cost if needed .

What can we do for you?

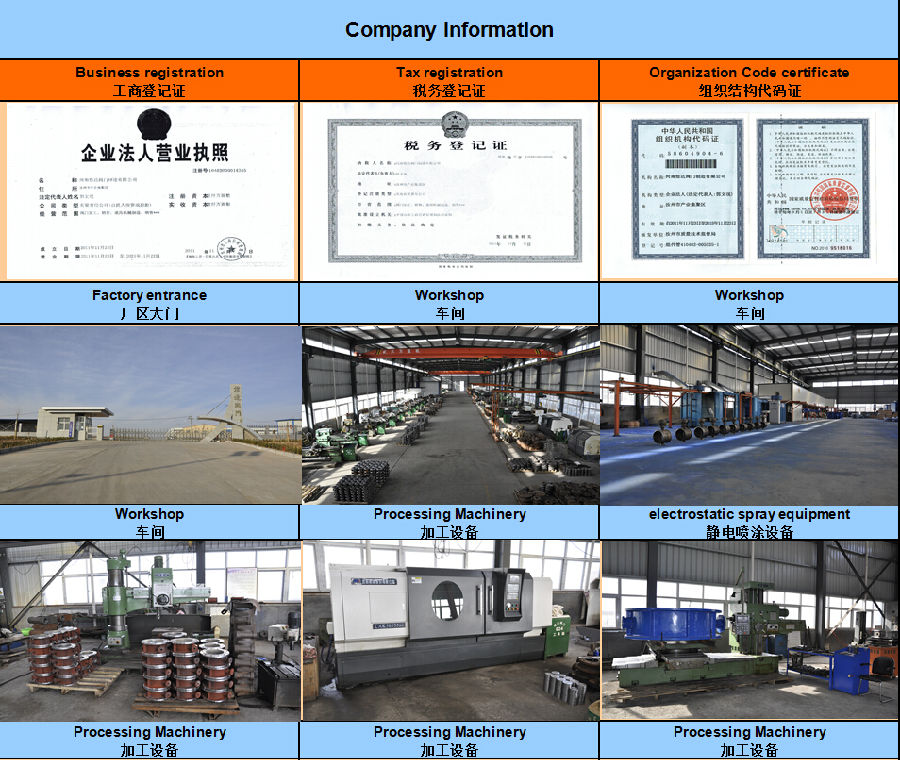

1. Save lots of your cost. As you know, more than 85% butterfly valves are made from Tianjin in China, our factory is located in this most advantage place too.

2. Your OEM orders are welcomed. We have own foundry, serve OEM customers from more than 23 countries.

3. Each valve is taken for two times pressure test before leave factory! Each butterfly valve has 24 months guarantee period.

4. You’ll never be low on supply---with our monthly capacity of 32000 sets.

5. More than 40 salesmen are always working with you and listening to you.

- Q:Butterfly valve sealing material has several?

- Nine: X1 (natural food gum), X2 (Heipalen), X3 (ethylene propylene rubber), X4 (neoprene), X5 (Ding Qing X6 (rubber), wear-resistant rubber (FPM), X7), X8 (silicon rubber), X9 (heat resistant ethylene propylene rubber)

- Q:Gate valve, butterfly valve and so on can do the valve so that?

- Valve can not be used to adjust the use, if the switch can not be in place, the medium flushing gate valve is easy to cause poor sealing!

- Q:Electric butterfly valve (not take the lead) what do you mean?

- Electric butterfly valve, as its name implies, consists of an electric actuator and butterfly valve, and the customer does not take the lead, that is, without the electric actuator, only the butterfly valve can be provided.

- Q:What is the meaning of the D341*5-10 / 16ZB1 turbine butterfly valve flange said?

- D: for clamp, 3: turbine head 4: flange connection 1: vertical plate X5: Ding fine rubber 10/16: nominal pressure Z: gray cast iron valve body, B1: valve plate material is ductile iron

- Q:Butterfly valve is the control valve?

- The flow characteristics of butterfly valves can be approximately equal percentage characteristics, with the positioner can do adjust, is mainly used in large caliber, straight stroke control valve more than 200 volume weight will be great, it suggests using the butterfly valve.

- Q:How to use the fire butterfly valve properly?

- Clamp and groove type and signal butterfly valve, the first two have what requirements of installation, the operating handle can rotate to open and close the valve installation, signal wiring, mouth down, to prevent water and caused a short circuit three line grounding and alarm line for leakage protection and monitoring of the valve open or closed, general are in line with the alarm valve or flow indicator matched with water, indicating the spacing of not less than 300mm, no other special requirements

- Q:Are fire fighting signal valves and signal butterfly valves the same thing?

- The same nature: both can open and close, there is also information back fed.Signal valves are collectively referred to as signal butterfly valves.

- Q:e.g. a patient with a prosthetic aortic valve and a patient with a prosthetic mitral valve. Also, can you get stenosis of mechanical valves or just tissue grafts?Thanks!

- mechanical okorder /

- Q:How many kinds of butterfly valves are there?

- Also known as butterfly valve, control valve has a simple structure, can be used for low pressure pipeline valve switching control is closed parts (disc or disc) is a disk, around the valve axis to achieve the opening and closing a valve, the valve can be used to control the flow of air, water, steam steam, all kinds of corrosive medium, mud, oil, metals and radioactive liquid media and other types of fluid. On the pipeline, mainly from cutting and throttling. Butterfly valve headstock is a disc shaped disc, in the valve body around its own axis of rotation, so as to achieve the purpose of opening or closing or regulation.[structure]The utility model is mainly composed of a valve body, a valve stem, a butterfly plate and a sealing ring. The valve body is cylindrical and has short axial length and is internally provided with a butterfly plate.

- Q:What do you mean, handle, butterfly valve, hard back and soft back?

- The butterfly valve of the handle butterfly valve is installed in the direction of the diameter of the pipe. In the butterfly valve body cylindrical channel, the disc shaped butterfly plate revolves around the axis, the rotation angle is between 0 degrees -90 degrees, when rotates to 90 degrees, the valve is fully open. This valve is mounted horizontally.Butterfly valve has an elastic seal and metal seal two types of seals. Resilient sealing valve. The sealing ring can be mounted on the valve body or attached to the periphery of the disc.The hard back is the metal seal, and the soft back is the elastic seal.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Wafer Type PTFE seated Butterfly Valve with Handle wheel/Lever operation

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 unit

- Supply Capability:

- 2000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products