Vokes®HVIP, VIP-Vacuum Insulation Panel, Fumed Silica

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

CHARACTERISTICS:

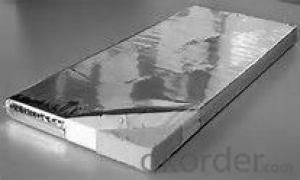

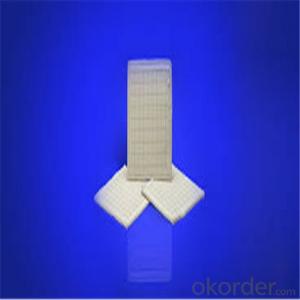

Vokes®HVIP is a micro porous thermal insulating panel with excellent insulating properties. The core material of Vokes® HVIP is fumed Silica. It’s sealed with a high gas barrier film under vacuum. The thermal conductivity < 0.004 W/mK .

A. Vokes®HVIP, adopts M- sealed at the back. It’s easy for workers to install, reduces the thermal bridges at utmost.

B. Vokes®HVIP, adopts advanced forming technology. It keeps the thermal performance as stable as possible. Even when the air enters, the conductivity will not be 0.018~0.02w/(m.k).

C. Vokes®HVIP, adopts full automatic line with strict quality policy, it ensures products in high level.

ADVANTAGES

Compared to traditional insulation materials, Vokes®HVIP with the extremely low thermal conductivity is outstanding at energy conservation. To achieve the same insulated result, Vokes®HVIP is far much thinner, lighter, and smaller.

-For freezer: Vokes®HVIP is able to save power 10%-30%, increase volume 20%-30%.

-For storage: Vokes®HVIP keeps 4-5 days thermal period, instead of 1-2 days using traditional insulation materials.

-For construction: Vokes®HVIP is easy to install because of its small conductivity and density. It’s safe, nonflammable, and recyclable. The working life is up to 50 years.

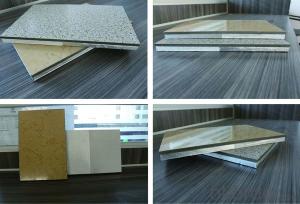

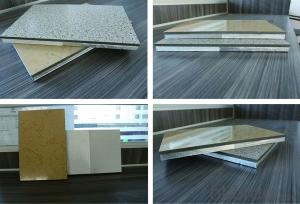

APPLICATIONS

Vokes®HVIP is a successful insulation solution in the following areas:

Buildings (Roofs, floors, walls, ceilings, etc)

Refrigeration and freezing (Freezers, medical thermotanks, blood banks, medical kits, refrigerated containers, etc.)

Automotive (Cars, trains, ships, air planes, etc.)

PRODUCT DATA:

Surface color: Silver

Geometry Rectangular shape (without protruding flanges*)

Density: 180 to 210 kg/m³

Thermal conductivity < 0.004 W/mK

Temperature stability: -70 °C to +70 °C (due to the film)

Thermal shock resistance: Not sensitive to heat & cold shock in the given temperature range

Humidity stability: 0 % to 60 %

Internal gas pressure: 1 mbar (at delivery)

Increase of gas pressure: approx. 1 mbar/year (at 20 mm thickness &

normal room conditions)

Standard dimension (L x W)(mm) 100x400/200 x600/400 x600/600 x1000/600 x1200

Thickness 10mm/15 mm/20 mm/25mm/30mm

Size tolerance • 0 to 500 mm: ±2 mm

Thickness tolerance: ± 1 mm

Specific heat capacity: 0.8 kJ/(kg·K) (at normal room temperature)

U-value: U 0.2 W/(m²K) (at 20 mm thickness)

Mass per area: 4 kg/m² (at 20 mm thickness)

Compressive strengh GB8813/EN8268- ≥0.15MPa

Flammability: GBB624- A

Service life: extrapolated, depending on application up to 50 years

- Q:What brand of refrigerator is using a vacuum insulation board? What kind of insulation board is better? More

- What do you mean if you want to get your own steel pipe fastener? Which city is in the city?

- Q:Is the thermal conductivity of the vacuum insulated plate used to protect the hot plate method?

- Supplementary feifei answer: 1.10kV to the ground safety distance (vertical) is 6 meters, if the 10kV live line below the minimum safe distance (vertical) is 3 meters, "power facilities protection regulations" provides strict construction, housing construction , If it is temporary construction, in the construction should contact the line unit, you can let them send on-site monitoring construction, but must ensure that the safety distance of 3 meters, than the steel pipe, scaffolding and other metal parts in the construction process should prevent the distance from the live line Excessive discharge causes electric shock. 2. If the use of crane construction, according to the "national shield shield uncle 墉 矫 堕 scared scared off the power grid company safety work procedures" provisions in the 5 meters away, to prevent the arm swing accidentally hit the live conductor. If the 10kV line around (both sides) construction, the safety distance and the vertical distance of the same provisions, if the lifting height beyond the live wire should be taken when the wind caused by the swing caused by electric shock 3. "Construction site temporary safety technical specifications" and " Power facilities protection regulations implementation details "provides only the moving objects, such as wires issued trees, houses and other buildings.

- Q:What is the best insulation material? To be waterproof.

- Under normal circumstances, the steel structure of the plant panel can be a single laminated steel plate, double laminated steel plate, composite color plate. Single-layer steel plate used for simple plant or temporary plant roof, this material is affordable, but the insulation effect is poor, easy to leak. Double laminated steel plate effect will be better. Composite color steel plate for the use of insulation materials sandwich practice, insulation and noise effects are very good, but as a roof, the national standard requires sandwich material must be flame retardant or non-combustible materials.

- Q:I ask, our home is the top floor, the summer is too hot, the walls and roof in addition to the use of insulation board, posted their own kind of tin foil, will not be useful?

- The traditional ceiling color steel tile composite composite 10 cm thick white polystyrene foam insulation board, the insulation effect is not very good, this is because the thermal conductivity of polystyrene foam board is relatively high (thermal conductivity 0.035W / (m · K) above), plus There is a gap between the foam board and the board, the temperature is very serious, the comprehensive thermal conductivity is generally higher than 0.05. The new polyurethane spray insulation material can be directly sprayed on the color steel tile, the thermal conductivity is low, only 0.022-0.024W / (m · K), insulation effect is 2-3 times the polystyrene board, is the insulation of all insulation materials Especially excellent material. Because in the construction of the use of direct spray molding technology, so that the polyurethane foam layer is not the overall burden of sewing the body to form a complete impermeability, fundamentally put an end to the possible deep Sex. Which play a preservative effect.

- Q:External wall insulation material which is good, external wall insulation materials

- Indoor insulation material that the best, fire, environmental protection, good insulation effect? ??Glass fiber. Good insulation. Glass fiber cotton with numerous fine gas holes, fibers arranged irregularly arranged, heat conduction breakdown of 0.03w / cm.k, is an excellent insulation material; . with non-flammable. Glass fiber cotton will not burn, no deformation, no embrittlement, can withstand 700 degrees of high temperature, the combustion performance to A1; . environmental non-toxic. As the glass fiber cotton in the manufacturing process does not add any adhesive, so there is no smell, high temperature will not be distributed when the toxic, pungent smell, smell, etc .; . high insulation. As the glass fiber cotton used in the raw material is glass, non-conductive, so it has a very high insulation; . corrosion resistance. Glass fiber is not afraid of strong acid, with a strong corrosion resistance, even if the use of long time will not reduce its functional characteristics; . good recovery Glass fiber contains numerous fixed cavitation, with excellent recovery, not afraid of any shock, tensile strength are more than 1.0kg; . do not want to light field scrambled decanoate containing mutual water. The moisture absorption of glass fibers is usually close to zero, do not worry about there will be water swelling caused by wet cracking of the situation. I hope my answer can help you.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Vokes®HVIP, VIP-Vacuum Insulation Panel, Fumed Silica

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords