Vinyl Click Flooring 3.5mm Thickness With Wood Designs MDM 016

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Packing Detail: In carton/pallet as requested.

Delivery Time: 20 days after received 30% prepayment.

Application:

Vinyl flooring is widely used in office,super market,hospital,house,

bathroom,Kitchen and other commercial places.

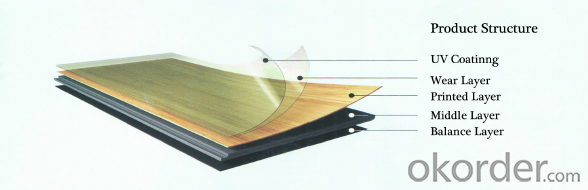

It is made of wear layer,pvc material and printed layer,which is a new type floor decoration material in the world.

Because environmental,cheap,easy to install,colorful and light than ceramic tile,

the vinyl foor is very popular.

Product Structure:

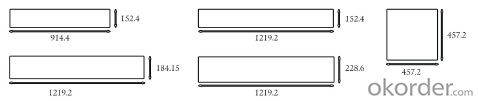

Size:

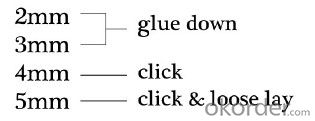

Thickness:

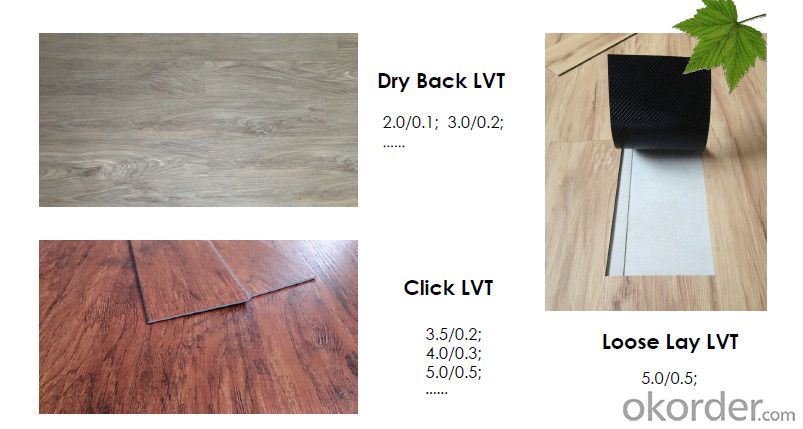

Specification:

Production:

- Q:What is the difference between hard and soft plastic floor construction

- Generally speaking: the difference between hard PVC and soft PVC is that the hard PVC is very hard, and steel, wood almost, and soft PVC is very soft, and rubber hose. Applications are very broad, the key is to look at the environment and occasions you use.

- Q:What is the name of the plastic floor on the supermarket, where is it?

- Plastic flooring selection coil special PVC glue, stairs, wall with adhesive

- Q:With this plastic floor mat bed can not? Will not have any impact on people

- Good insulation, but not breathable, it is best not to use directly on the bed! It's better to use a sponge mattress!

- Q:Home decoration house, because there is no time, all to the decoration company, now just installed, found the decoration company to use in the bedroom floor is only 0.7 cm thick, and skirting the bedroom are plastic, and the rest of the baseboard and tried hard to break. I would like to ask you how long this line can be used? Need to be removed and replaced with good quality? Will be removed when the...

- Just let him change it for you. The truth is the same, but the baseboard, do not have too much to worry about, plastic skirting is allowed gb.

- Q:PVC plastic floor can be used as a kitchen operating room, right?

- Seems to be floor paint How do I know what it is?

- Q:What are the disadvantages of PVC plastic floor

- PVC plastic floor has many advantages, it also has shortcomings, but compared to other plastic floor, PVC plastic floor has been considered a good

- Q:Plastic floor and socket contact for a long time easy to catch fire

- The wood floor is a non-conductive insulator. How can it catch fire? Wires don't conduct electricity on wooden floors.

- Q:Home decoration with plastic floor, please? What are its strengths and weaknesses?

- To prevent accidental injury; skid resistant, not affected by temperature, wet deformation, reducing the noise comfortable and 5 color pattern is rich, personalized to meet the actual demand of fire; 6

- Q:Dog feces in the plastic floor on how to clean, 84, washing powder, detergent are used, or brush off, how to do? What cleaning

- Generally buy plastic floor is the choice of coil, plastic floor how to install, plastic floor price, plastic floor how much money

- Q:EVA plastic floor and PVC plastic floor which is good

- You don't know what is the use of hanging material, I think it is a good floor, PVC

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Vinyl Click Flooring 3.5mm Thickness With Wood Designs MDM 016

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Hot Searches

Related keywords