Vibrating Screen-For Stone Aggregates and Ores

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 200 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Circular Vibrating Screen

Type: Necessary Auxiliary Equipment

Input Size: 0mm--1000mm

Processed Materials: Limestone, Granite, Gabbro, Basalt, River Stone, Coal Gangue, Quartz, Diabase,Iron Ore, Copper Ore, Zinc Ore, etc.

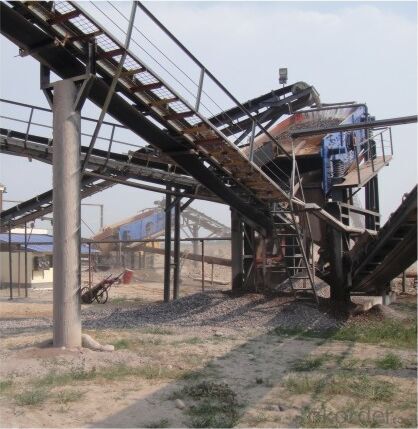

Applications: Aggregates Shaping, Mechanism sand, Bituminous Concrete, Metal Mine, Chemical, Road, Railway,Metallurgy, Construction, Highway, Water Conservancy

Capacity: 10-500TPH

The moving road of this screen is similar as a circle, so it is called Circular Vibrating Screen. Circular Vibrating Screen is of multilayer and high efficiency. The eccentric shaft vibration exciter and eccentric block helps to adjust amplitude. This kind of screen is of long screening stream line and more sieving specifications. So it is widely used for grading in the industries of quarry, building material, transportation, energy, chemical industry, etc.

1,It uses cylinder-type eccentric shaft and eccentric block to make strong vibrating force.

2,Beam is connected to the main body with bolts, has the feature of high strength.

3,The side plate of the screen box use the steel which make the boiler, the steel have high strength and strong impact resistance.

4,It adopts the structure of small amplitude, high frequency, large obliquity to make the screen with high efficiency, large handing capacity, long life span, low consumption and little noise.

5,The vibrating screen uses the motor to drive the eccentric shaft to make the screen body periodically along with the direction of vibration force. The materials make circular movement on the screen to realize sieving. Circular vibrating screen consists of vibration source, screen body, screen mesh, shock absorbing device, base frame etc. It has the features of reasonable structure and long durability.

Detail Specification:

| Model | Screen Size(mm) | Layers | Screen Mesh (mm) | Max Feed Size(mm) | Capacity (t/h) | Power (Kw) | Vibrating Frequency(r/min) | Double Swing (mm) |

| 2YK1237 | 3700*1200 | 2 | 3-80 | 100 | 10-80 | 11 | 750-950 | 5-9 |

| 3YK1237 | 3700*1200 | 3 | 3-80 | 100 | 10-80 | 11 | 750-950 | 5-9 |

| 2YK1548 | 4800*1500 | 2 | 3-80 | 100 | 30-200 | 15 | 750-950 | 5-9 |

| 3YK1548 | 4800*1500 | 3 | 3-80 | 100 | 30-200 | 15 | 750-950 | 5-9 |

| 2YK1848 | 4800*1800 | 2 | 3-80 | 100 | 50-250 | 18.5 | 750-950 | 5-9 |

| 3YK1848 | 4800*1800 | 3 | 3-80 | 100 | 50-250 | 18.5 | 750-950 | 5-9 |

| 2YK1860 | 6000*1800 | 2 | 3-80 | 100 | 60-300 | 22 | 750-950 | 5-9 |

| 3YK1860 | 6000*1800 | 3 | 3-80 | 100 | 60-300 | 22 | 750-950 | 5-9 |

| 4YK1860 | 6000-1800 | 4 | 3-80 | 100 | 60-300 | 30 | 750-950 | 5-9 |

| 2YK2160 | 6000*2100 | 2 | 3-80 | 100 | 80-400 | 22 | 700-900 | 5-9 |

| 3YK2160 | 6000*2100 | 3 | 3-80 | 100 | 80-400 | 30 | 700-900 | 5-9 |

| 4YK2160 | 6000*2100 | 4 | 3-80 | 100 | 80-400 | 30 | 700-900 | 5-9 |

| 2YK2460 | 6000*2400 | 2 | 5-80 | 100 | 100-500 | 30 | 700-900 | 5-9 |

| 3YK2460 | 6000*2400 | 3 | 5-80 | 100 | 100-500 | 37 | 700-900 | 5-9 |

| 4YK2460 | 6000*2400 | 4 | 5-80 | 100 | 100-500 | 37 | 700-900 | 5-9 |

- Q:Is the mud shaker the same as the pulp shaker?

- Working principle of pulp vibrating screenThe same as the common vibrating screen, all the screens pass through the sieve hole by setting the sieve plate of the proper aperture, and the unqualified impurities are blocked because the geometrical size is larger than the sieve hole.

- Q:Is the vibrating motor power used in the shaker the better? Please, everybody

- Choose a good vibration screen, to see the overall configuration, rather than a single look at the power of the motor.

- Q:What problems should I pay attention to when buying a vibrating screen?

- In the purchase of vibrating screen, mainly to see the characteristics of your screening materials: particle size, how much to the screen, moisture content, viscosity, specific gravity, so you can calculate how much, what kind of models to meet your production requirements.

- Q:How do I change the strainer for the vibrating screen?

- There is no noise because of stretching tension, the tension and the network when the first slightly taut point, then the four angle taut, continue tight ring, after a good stretch on the machine, with the upper frame body is pressed down, fasten the ring on the line, stretching up noise is small

- Q:How can eccentric wheels be justified only if a vibrating screen with one eccentric wheel is installed?

- The eccentric wheel frame is often crack, you may consider a symmetrical arrangement of two, the total mass is half of the original quality, also should consider the change often split components of materials, should be soft and not easy to crack the material, the round to crack place.

- Q:Circuit principle and connection method of Derek vibrating screen

- The whole control cabinet does not work all the way or a few ways, the alarm light is on, check whether the fuse of this road is broken, whether the thyristor is damaged or shorted, and whether the electromagnetic vibrating coil is burned out,

- Q:What are the advantages of ZKS vibrating screen?

- ZKS mining vibrating screen adopts new energy saving vibration motor or vibration exciter as vibration source, and the rubber spring support and vibration isolation has the characteristics of large processing capacity, high screening efficiency and convenient screen changing.

- Q:What are the damping springs on the vibrating screen?

- The vibration damping spring is an indispensable component in the vibrating screen. The vibration damping spring on the vibrating screen is an important part of the sieve body and the base, and acts as a buffer in the process of the work of the vibrating screen, so that the material can keep forward movement on the screen without damaging the vibrating screen.

- Q:How is the application of compound spring in vibrating screen?

- The utility model has the advantages of good stability, high load capacity, vibration isolation, noise reduction and the like.The utility model is more suitable for large-scale vibrating equipment in mines, coal, metallurgy and other industries.

- Q:Do you have a linear vibrating screen with a rake angle?

- Hello, the linear vibrating screen has a dip angle, called a dip angle linear vibrating screen

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Vibrating Screen-For Stone Aggregates and Ores

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 200 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products