Vial Tubing Plane Shoulder Vial, Slanted Should Vial

- Supplier:

Triumph Junheng Co.,Ltd

Triumph Junheng Co.,Ltd

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100000 pc

- Supply Capability:

- 1000000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Vial Tubing Plane Shoulder Vial, Slanted Should Vial

The converting products workshop of the plant has a 100000-level clean room that meets GMP standards, which provides superior production conditions for the production of glass containers and effectively avoids the impact of dust and bacteria on product cleanliness. The inspection system with 7 cameras and 360 continuously rotating and shooting, to detect the glass container body,mouth, shoulder, bottom,inner diameter,edge blind area and mouth bottom edge, as well the dimension, objects inside the container, cosmetic defects (bubbles, impurities and stones).The unqualified products such as crooked container are automatically eliminated, with a detection accuracy of 0.02mm, which ensures that the quality of the glass containers can reach the domestic YBB standard and the international ISO standard. "Excellence Centre"is a project established by Triumph Group and the world leading pharmaceutical packaging material manufacturer-Stevanato Group(Italy). The goal is to introduce world standard tubular glass containers production technology, technical process and quality standards to the Chinese market and make our company's products to keep up with international top standard.

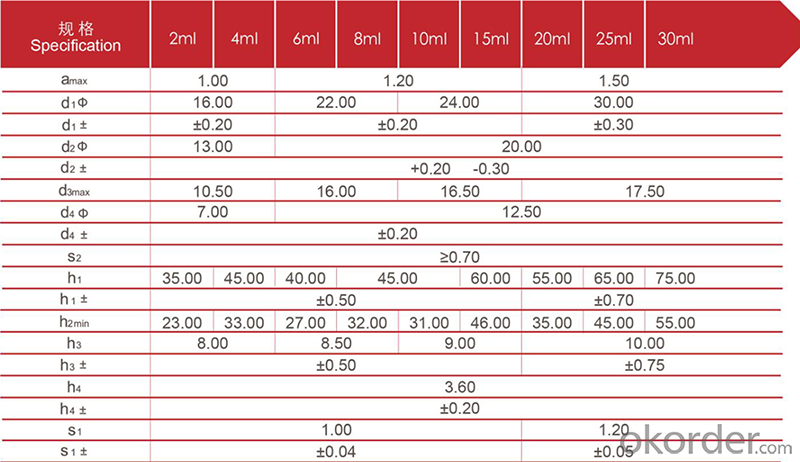

Vial Tubing Plane Shoulder Vial

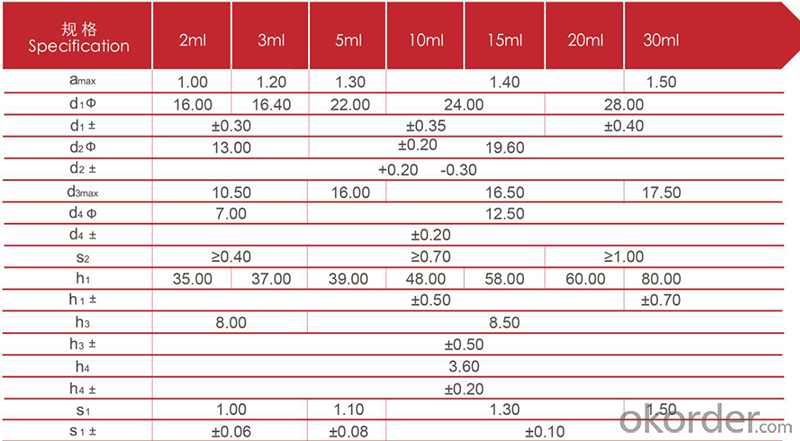

Vial Tubing Slanted Should Vial

Nationwide Seven Production Bases to Meet the Customers' needTriumph Junheng Co.,(hereinafter referred to as "Triumph Junheng") is a state-owned andprivate mixed ownership enterprise, Triumph Group of CNBM is the controlling shareholder.It ismainly engaged in the research and development, producing and sales of neutral Borosilicateglass tubing(hereinafter referred to as "Neutral Borosilicate glass tubing") and convertingtubular glass products. It has seven production bases located in Handan, Qingdao, Chongqing,Puyang, Anyang, Nanchang and Zhenjiang, which are expected to produce totally 170,000 tons of glass tubing and 136,000 tons of tubular glass container when they are reach full capacity. It is the first high-tech company which realizes stable mass production of high-quality Neutral borosilicate glass tubing with its "oxygen combustion + electric boosting"melting and Danner Tubing drawing technical process in China. It has leading R&D capabilities in the domestic pharmaceutical glass packaging industry, and can provide professional and personalized solutions of pharmaceutical glass packaging materials for materials for tubular glass converting and pharmaceutical companies.

Triumph Junheng builds a comprehensive research and development center for pharmaceutical neutral borosilicate glass in accordance with CNAS certification specifications. Continuously improve the level of laboratory quality management, minimize product quality risks, and meet the requirements of customers and regulations for the authenticity and reliability of testing/calibration to the greatest extent. The R&D center has a team with 30 people, covering various key technical fields such as raw materials analyzing, batching, melting, forming,and post-processing. The center has a building area of 800 square meters and consists of a precision instrument room, a physics laboratory, a chemical laboratory, a balance room, and a high temperature laboratory., Reagent room, equipped with 30 sets(sets)of R&D equipment such as atomic absorption spectrometer, expansion coefficient meter, and electron microscope. The R&D

center focuses on new technologies, intelligence, low energy consumption, localization and standardization, and actively undertakes national and local R&D projects to continuously achieve new technological breakthroughs.

Companys proucts have passed the Qulity inspection and Testing conducted by the national authoritative inspection agencies: Beijing Pharmaceutical Packaging Materials Inspection Institute and International Third Party Testing Agency-SGS. The product quality is fully in line with EP (European Pharmacopoeia), USP United States Pharmacopoeia),JP (Japanese Pharmacopoeia),According to the standard requirements of ISO12775 and the standard of "Neutral Borosilicate Glass Tubing" with Code YBB0012005-2-2015 approved by The National Food and Drug Administration. The expansion coefficient, boron content and hydrolitic resistance of products all have reached the international advanced level.

Quality Inspection

The international advanced automatic online inspection system has been adopted in the production line, which can automatically eliminate unqualified products with defects of dimension and cosmetic and unaligned ends treatment.

Automatic Packaging System

The automatic packaging system can complete the work of heat-shrinking into bundles and stacking into trays, effectively avoiding cosmetic defects such as scratches and impacting caused

by manual operation, ensuring the fastening of each bundle of products and the neatness of each tray.

- Q:How is glass made?

- Technological process:1, raw materials broken: the above raw materials broken into powder;2, weighing: according to the list of ingredients, called a certain amount of powder;3, will be called: the mixed powder mixing, stirring into a batch (colored glass and colorant);4, melting: the mixture into the glass furnace, melting at 1700 degrees into glass;5, forming: the glass liquid into a tin bath (float), pull machine (lattice method), rolling machine (rolling method, adding metal wire is wire glass), forming the flat glass;6, annealing: the molding of glass products into the annealing furnace annealing, balance the stress, to prevent self cracking.

- Q:What is the raw material of glass products?

- Ordinary glass is the raw material of soda (sodium carbonate), limestone (calcium carbonate) and silica by high temperature reaction, with sodium silicate, calcium silicate and silica products, according to the needs of different substances will add color.For example, adding chromium oxide (Cr2O3) glass, is green; adding manganese dioxide (MnO2), purple glass; adding cobalt oxide (Co2O3) glass, blue glass, copper, copper oxide is high if the glass appeared blue and green; in order to lower the price of cuprous oxide (Cu2O) when there is red glass.Now, people use the oxide of rare earth elements as coloring agents to make all kinds of high-grade color glass. Colored glass doped with rare earth elements has a bright, bright color and even changes colors in different light. For example, in the glass of neodymium oxide has this characteristic, it shows purple red in the sunlight, in the fluorescence of purple blue, very beautiful. There is a kind of glass that changes with the intensity of light. People use it as the lens of glasses and the window glass of the house. With this kind of glass as a window, the room can maintain a certain brightness, and no longer need to use curtains to shade, so some people call it "automatic curtain"". It can prevent the UV rays of the sun through the library and Museum Library, installed on the glass, can protect the books and cultural relics from UV damage, in addition to the rare earths, directly adding tungsten and platinum in the glass, can also be made of glass.

- Q:The preparation process of glass and the basic material and the function of raw materials

- Silica sand, quartz sand or sandstone with SiO2 framework structure for glass, glass forming;The role of soda to help melting sand;

- Q:Glass fiber reinforced plastic (FRP) is a new type of composite material. What is the raw material?

- The first type of glass fiber reinforced plastics is a composite of glass fiber and phenolic resin. It is a glass fiber impregnated with phenolic resin liquid raw material, after molding, pre molding, and then the phenolic resin curing, made of glass fiber reinforced plastic. Corrosion resistance and long service life. Glass fiber reinforced plastic is a kind of high-quality composite material. It has a special anti-corrosion function for acid, alkali, salt, oil and other corrosive media, and will not rust. The average PVC life is 15 years, while the glass steel life is 50 years.

- Q:What kind of material is the toughened glass film made of mobile phone?

- Tempered glass membrane should be made of tempered glass = =, but this film is not so magical propaganda

- Q:Does anyone know iPhone's toughened glass production process? Thank you

- Chemical strengthening of good products, or the need for ultrasonic cleaning machine cleaning (quality inspection);(if you need a AR antireflection coating processing, processing, without careful confirmation, currently do not know the first AR coated glass is strong, whether it is feasible, if not feasible, AR coating will in strong, should be on the back of the glass doesn't need AR coating; positive surface is there, I'm not sure. There is supposed to be, the film will affect the resistant to scratching, maybe not, I'm not sure)

- Q:Can ordinary white glass (Bai Jiuping) replace quartz glass?

- Quartz glass is a kind of special industrial technology glass made of silicon dioxide. It is a very good basic material.

- Q:What are the main materials for making glass?

- Silica is the main raw material made of silica on the earth reserves is great. Silica is the main raw material for the main raw material is made of glass stones. The silicon content of different rocks are different. In our life of these materials is the most common.

- Q:What kind of glass material is used in the aquarium?

- Toughened glassToughened glass is a kind of high strength safety glass which is heated by glass to softening point and then cooled rapidly. Under the same thickness, the flexural strength of tempered glass is 4-5 times higher than that of ordinary glass, and the impact strength is 5 times higher than that of ordinary glass. Toughened glass has a strong thermal stability and can withstand severe temperature changes without damaging it. The most important feature of tempered glass is safety. This kind of glass is broken into similar honeycomb particles, so it can avoid the harm to human body. Note: after tempering, the glass can not be cut, drilled, slotted and so on. Because glass is broken into honeycomb like particles that are completely irreparable, it is not recommended for use on aquariums!

- Q:May I ask what specific aspects of German foam glass and foam glass made in China are?

- Germany first foam glass from the production process is automatic production line, proportion of raw materials, mixing, grinding, into the furnace foaming, stripping, pipeline operations, and 24 hours of uninterrupted production, full computer monitoring, the whole process of online cutting, according to the requirements of automatic generation of the required thickness and size. 100% waste glass as raw material.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Vial Tubing Plane Shoulder Vial, Slanted Should Vial

- Supplier:

Triumph Junheng Co.,Ltd

Triumph Junheng Co.,Ltd

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100000 pc

- Supply Capability:

- 1000000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords