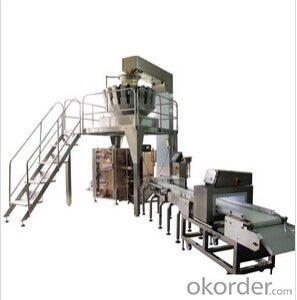

VG42 High Speed Packaging Machine ( MD18 heads combination weigher)

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 20 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

We are a professional manufacturer of food packaging machines. We are major in the packing machine for more than 11 years.

In China, we are the leading company in this area. Our machine exported over 40 countries and welcomed by the customers since good quality but inexpensive. The best quality of the machine will make user increase productivity and reduce maintenance costs, achieve higer economic efficiency. We got CE & ISO9001:2000 certification. Also, we have perfect after-sale service, when the packing machine has problems just send us an E-mail, our engineer will reply you how to solve the problem or go to your factory. We have the comprehensive abilities in many fields such as design and development of whole projects, production and manufacture, installation and testing, technical training and surpport. Adhering to the spirit of "quality, efficiency, credibility and practicality", we guarantee the high quality of our products.

With the market spreading over Europe, America and Southeast Asia, we sincerely hope to cooperate with customers from all over the world. Please contact us for more details. We ensure to provide qualified products with the best service.

VG42 high speed packaging machine

* Three Specifications

The machine is controlled by three servor motors, with continuou pulling film system and of maximum speed can catch 120 bags/min

Item | Content |

Capacity | 100-120 bags/min |

Bag size | (L)50-300mm (W)50-200mm |

Max film width | 420mm |

Film thickness | 0.04-0.09mm |

Pulling belt type | Intermittent pulling film |

Air consumption | 0.8Mpa 0.3m3/min |

Main power/voltage | 4KW/220V 50/60Hz |

Dimension | L1850*W1100*H1450mm |

Weight | 700kg |

Features

servo motors for film drawing down system. Automatic film rectifying deviation function.

* Horizontal sealing controlled by servo motor;

* Famous brand PLC. Pneumatic system for vertical seal and horizontal seal;

MD18 heads combination weigher

Features

*Adopt high precision digital weighing load cell and A/D module to get preciser weighing than before.

*LCD operating display with multiple languages such as English, Russian, German, Spanish,Italian, etc.

Specification

Item | Parameter |

Drive method | Stepper motor |

The max weighing | 3000g |

Type of weight setting | 99types |

Accuracy | ±0.1~1.5g |

Max capacity | *80bags/min |

Hopper Capacity | 150-2000ml |

Type of hopper | Double layer without memory |

Dimension | L1150xW950xH1129mm |

Voltage | 2KW 50/60/HZ 220V |

TK9 Z type Bucket Elevator (including the vibration feeder)

Features

The conveyor is applicable for vertical lifting of grain material in departments such as corn, food, fodder and chemical industry, etc. It’s used for vertical feeding of grain or small block material.

Supporting Platform

Features

The supporting platform is solid will not affect the measurement accuracy of the combination weigher. In addition, the table board is to use the dimple plate, it is more secure, and it can avoid slipping.

Specification

The size of the supporting platform is according to the type of the machines.

TP200 Finished Products Conveyor

Features

Automatically transport the finished products to the turn table which can rotation 360° convenient packaging.

- Q:What are the main functions of packaging machinery?

- In order to meet the requirements of many customers, our company has learned from all aspects of the role of packaging machinery and equipment, so that we need customers for reference

- Q:What are the main plastic forming processes?

- 3. cold pressing molding. Cold pressing molding is also called cold pressing sintering molding. The difference between the cold press molding and the ordinary compression molding is that the material is pressurized and molded at room temperature. The mold after release can be heated or cured by chemical action. This method is used in the forming of polytetrafluoroethylene and some high temperature resistant plastics (such as polyimide, etc.). The general process is three steps of billet sintering cooling.4. transfer molding. Transfer molding is a molding process for thermosetting plastics. When molding, the mold is heated and softened in the heating chamber and then pressed into the mold cavity where it has been heated. According to the different types of transfer molding equipment form: trap type; the tank; the piston.The requirement of plastic molding for transfer molding is that the plastic should have a greater fluidity before reaching the curing temperature, and the curing rate must be faster at the curing temperature. Phenol, melamine, formaldehyde and epoxy resins can meet this requirement.Transfer molding has the following advantages: less waste edge products, can reduce the processing quantity; second molding with fine or brittle insert and perforation of the products, and can keep the insert and the hole position is correct; the product performance is uniform, accurate size, high quality; the mould wear small. The disadvantage is that the manufacturing cost is high compression mold die; the plastic loss; the fiber reinforced plastics for fiber orientation and anisotropy; and around the insert around the plastic, sometimes due to melting is not strong and make the products according to the strength reduction.

- Q:What's the best place to use the pillow type packing machine?

- In the early communication can be reflected, and sometimes non-standard customized to see the level of Technology

- Q:What are the packing machines?

- They make packing equipment. There are many kinds of food packaging, sealing packaging, pillow type packaging machine. I hope I can help you.

- Q:What are the structures of the packaging machinery?

- Is a professional engaged in "packaging machinery" research and development, production, sales as one of the multinational enterprise groups. It is the largest manufacturer of packaging machinery in china. Located in the Chinese science and Education City - Hefei, the geographical position is superior, the traffic condition is convenient, and the sale network extends the whole country. Is far from, with a group of the world's top machinery manufacturing R & D team, specializing in all walks of life packaging enterprises, for the efficient production of enterprises to provide power. It is a large enterprise that put forward the concept of packaging automation earlier in china. Brand with strong economic strength, first-class R & D level, advanced business philosophy and good brand service, more and more people all over the world are respected and trusted. The entire manufacturing process in full accordance with the highest standards of global manufacturing; at the same time according to the quality standard of global market development process, operating procedures and quality control system of production, all is "far Machinery" have reached world-class standards. "Far distance machinery" combines the characteristics of all kinds of products in China, such as packaging machinery, food packaging machines, two times packaging machines, powder packaging machines, particle packaging machines, liquid packaging machines, weighing machines, and so on.

- Q:What's the fastest packing machine?

- Because the packaging machine type is more complicated, according to the state, liquid, bulk, powder, granular packing machine; according to the function of packaging, packaging, packaging machine in outsourcing; according to the packaging industry, food, daily chemical industry, metal parts, textiles and other packaging machine; according to the packing station. A single station and multi station packing machine; divided by automation, automatic packing machine, also has semi-automatic and so on. According to the form of sealing, it can be divided into back sealing type, three sides sealing, four sides sealing, triangle and so on. According to the product form, it can be divided into pillow type packaging machine, vertical packaging machine, vacuum packaging machine, sealing machine and so on

- Q:What kind of reducer is commonly used in packaging machinery?

- There are many kinds of packing equipment, such as food packing, filling, quantitative packing, back channel packing and so on

- Q:What is a packaging machine?

- Well, before and after the associated processes, such as cleaning, stacking and disassembly. In addition, the package also includes the measurement or in the processes of stamp packages. Mechanical packaging products can improve productivity, reduce labor intensity

- Q:What is the price of a small jujube packing machine?

- Mainly see what some requirements, automatic metering packaging or vacuum packaging machine, after understanding can determine the price.

- Q:What machine does the packing carton machine have?

- Since its establishment, the company has continued to provide specialized packaging equipment and transportation equipment for domestic first-class enterprises, as well as perfect solutions for automated transportation systems.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

VG42 High Speed Packaging Machine ( MD18 heads combination weigher)

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 20 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords