Vertical Can-type/Barrel Pump .

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

1. Description

Vertical barrel pumps are multistage, radically split with an outer casing. Fist stage impeller is generally suction impeller, the axially forces are balanced by a thrust ball bearing. Balancing the drum structure can be accomplished when the differential pressure is large. The outer casing only bears the suction pressure, the length of the outer casing and the pump installation depth depends on NPSHr performance requests. If the pump is installed on a tank or pipeline, the outer casing is not necessary.

Light oil lubricated, it has an independent internal recycle automatic lubrication system. Hydraulic dynamic bearing is in the suction end of the pump. Suction and discharge is above the installation flange.

2. Application

Suitable for various liquids include clean or dirty, low temperature or high temperature, neutral or corrosive

Low temperature engineering, power plant

Pipeline pressure increasing

Petrochemical offshore oilfields

LPG engineering

Refinery

3. Technical Data

Size: DN 40~200mm

Capacities to 800m3/h (3522GPM)

Heads to 800m (2625ft)

Pressure to 10MPa

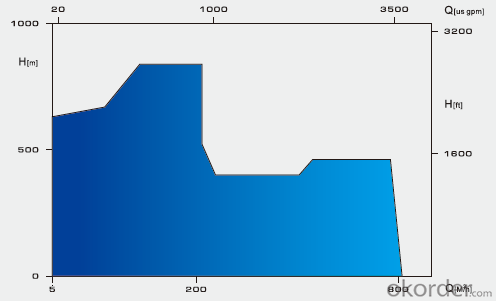

4. Pump Performance

5. FAQ

1 Are CNBM pumps available in DIY stores?

Yes, currently, we’re available for DIY stores all over the world.

2 Where do I have to send pumps for service?

You must send them to the CNBM PUMP Service Point or, after contacting Customer Care, to the CNBM PUMP service center in China.

3 Are your pumps acid-proofed?

To choose the right pumps for chemical applications, we do need further details on hydraulic operations as well as on the type, concentration and temperature of the liquid.

4 Can your pumps mount Eff.1 motors

Currently, only on request though this will shortly be a CNBM standard.

- Q:I am new to saltwater tank, and i what to add a sump to my tank, but I don't know what to add to it. what water pump? do i add the filter to the sump or does the filter stay in the tank.

- you do no longer use siphons to flow water to the sump, you employ an overflow and pipes. the point of having the overflow in a tank with a sump is that the pass between the two tanks would be even. while the water is pumped returned to the tank and reaches a definite point that water will then pass returned to the sump. If the capability will fail then the pump will end working, so no water would be moved returned into the tank, no water will overflow returned. the priority with 2 pumps would be that no 2 pumps are comparable. One pump is 2 hundred gallons consistent with hour, the different is 199, next one is 195 regardless of being from an identical authentic line and type. So in case you have a 2 hundred and 199 GPH you will finally end up with the two the tank or the sump spilling after some hours.

- Q:My pt crusier water pump went out. Are there any tricks to fixing it? My husband wants to take a crack at it because it is 800.00 to have it fixed by a local mechanic here in Spring Hill. If anyone knows any tricks to doing it or where I can get it done cheaper in Spring Hill?! Let me know!!!!

- The water pump is driven by the timing belt on this motor. If it is not done right, you could cause serious damage to the engine. Actually $800 to change the pump and timing belt is reasonable. To lower the price further you could negotiate buying your own parts. Good luck.

- Q:can bad water pump make car overheat?

- The water pump is what moves the coolant through the engine so if it is bad the coolant doesn't get to where it needs to go causing overheating. A bad thermostat will cause the same thing.

- Q:A mechanic replaced my timing and other belts on my 2001 Mitsubishi Galant 4 cylinder today but not water pump. He said the water pump looked good. All the other mechanics I talked to told me they had to replace the water pump. This mechanic said the belts were not connected to the water pump in this car and therefore the water pump was ok. The car has about 100500 miles on it. Is this bad or should I call him back and ask him why he didn't change the water pump. I don't want to pay more later.

- no your water pump should be fine if the belt wasnt spinning the water pump then nothing was moving to break or whatever the way you can tell if your water pump is bad is it will leak green antifreez out of the front of the motor and you will see green puddle on the ground but if its not leaking then its good

- Q:Water pump motor often caused by water can not run, how can solve?

- You are immersed in water or oil pump pump, if flooding do not be afraid, if you put oil thread wrapped with waterproof tape, general water pump inlet is in the end, you want what the price of copper or aluminum pumps, the price is basically the same, do not buy too cheap water pump

- Q:I was was wondering how to calculate the head flow rate from a water pump. The water pump outputs 2 bar, which means that it will push water up to 20m in height. It also has a throughput of 2000 litres per hour.I want to pump water up to my loft, which is approx 15m above the pump.What will the flow rate be at this height? Is it a linear calculation of percentage of drop from maximum head height multiplied by the flow rate, (eg 5/20 * 2000 = 500 litres per hour?), or is it more complicated than that?

- If your pump has more capacity than you need, you can always restrict the discharge and create extra artificial head.

- Q:Hello everyone, is the general household deep well pump capacitor how to pick up ah, 220V voltage, a capacitor, capacitor, there are 2 lines, but the motor is 3 lines, how can I put these 7 lines together?.Please don't copy professional theories from others.

- 220V has two lines (lines 1, lines 2)There are two lines of capacitance (line 3, line 4)There are three lines on the motor (line 5, line 6, line 7)3 11 52 64 7That's plain enough. To change the turn, change any two of the 5, 6, 7, three lines

- Q:I have never had to deal with this and I am probably worrying about nothing but every time I run water, even for a second, the pump starts clicking on and off. Is it supposed to do it with every little thing? Every time the toilet flushes, or the water gets turned on to wash hands it goes off and keeps constantly going off until the water is shut off. Is this what it's supposed to do?

- No, sounds like tank is water logged. Turn off pump, drain tank, replace plug and prime pump. It needs air to pressurize, water don't compress. hope this is a quick fix for you.

- Q:My water stopped working and my tank emptied. I replaced the pressure switch and the gauge. It still didn't work. The well is about 110'. I pulled the pump and replaced it (1/2 HP, 10 gpm, 2-wire). It still doesn't work. The old pump was 15 years old. The one before only lasted 7 years. The water has a lot of sediment. I have never done this before, but it seemed straightforward enough. The wires on the pump were not differentiated in any way (same color). Could I have put the wires together incorrectly? Could I have put the switch in wrong? It doesn't click on when the breaker is turned on. What else could be wrong? Could the breaker be bad? It wasn't kicked out.

- Sounds like the vertical check valve between the end of the pump line and the pressure tank is bad and allowing the water to go back down the pipe when the pump isn't running. Papaw

- Q:Theirs a house on a hill and a pond at the bottom of the hill what kind of pump can pull water 50ft up a hill?

- None. Atmospheric pressure is equivalent to about 10m of water height = 30ft. When a pump pulls water (or any liquid), up a certain height of pipe, it does do by lowering the pressure. In a centrifugal pump (the most common type for handling water) the point of lowest pressure is the centre of the rotor (the eye of the pump). In order to pull water 10m up, equivalent to 30ft, the pressure at the eye of the pump would be 0, which is unattainable. Not only that, but the water will begin to boil at a certain low pressure determined by the temperature of the water. That pressure at which the water begins to boil determines the lowest pressure than can exist at the eye of the pump and is a critical design variable. There are several ways to circumvent the problem of pumping water higher than 30ft. One would be to install more than one pump, with one of the pumps half-way up the hill. The other would be to install one single pump, but to place it near the pond. There is a limit to how high a pump can PULL (suck) water, but there is no limit, other than the amount of pressure the pum can generate and the piping can handle, to how far up a pump can PUSH water. If you need to puch water higher, you can always buy a bigger pump.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Vertical Can-type/Barrel Pump .

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords