Vermiculite Grinding Mill of excellent quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

ackaging & Delivery

| Packaging Detail: | standard container |

| Delivery Detail: | 35 working days |

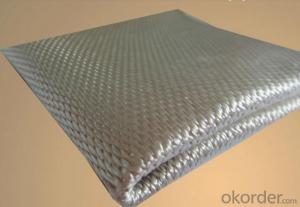

Vermiculite Grinding Mill

Vermiculite Grinding Mill is the equipment specializing in producing fine and superfine powder of non-inflammable, non-explosive and brittle materials with Moh's hardness under six, such as calcite, chalk, limestone, dolomite, kaolin, bentonite, talc, mica, magnesite, illite, pyrophyllite and vermiculite, sepiolite, attapulgite, rectorite, diatomite, barite, gypsum, alunite, graphite, fluorite, rockphosphate, Kalium ore, pumice, etc., totally more than 100 kinds of materials.

Vermiculite Grinding Mill Working Principle:

After crushed by hammer crusher, the large materials become small ones and are sent to storage hopper by elevator, edge of then evenly sent to the upper distribution plate of the turnplate by vibrating feeder and sloping feeding pipe. When the grinding mill is at work, all the grinding rollers are rolling in the ring, and the materials are driven to the edge of the turnplate by the centrifugal force and fall down into the grinding chambers where the materials are repeatedly pressed, crushed and grinded by the rollers. The high-pressure air blower constantly inhales air within the grinding mill and, in turn, the air flow with crushed materials are brought to the classifier whose high-speed impeller will screen the airflow: the unqualified particle size will fall and return to the mill for being reground while the qualified particle size mixed with air will go into the cyclone powder collector. Most of the qualified powders will fall an exit from the discharging valve at the bottom; a small proportion of the fine powders, with airflow, moves to the dust cleaner, and clings to the surface of the filter bags. At the same time, the fine powders clinging to the surface fall down by the sudden vibration of the filter bags, which is caused by the instantly ejected high-pressure gas controlled by the pulse valve. The materials from the above two lots are sent by the conveyor at the bottom to get finished powders packed. In addition, filtered clean air will be emitted from the air outlet of muffler in the end.

Features of Vermiculite Grinding Mill:

1. High Efficiency

Under the same finished final size and the same motor power, the capacity of micro powder grinding mill is twice as much as jet mill, mixing grinder and ball mill, and energy consumption decreased 30%.

2. Long lifecycle of spare parts

The ring and roller are forged by special material with high utilization,the lifetime can reach 2-5 years for grinding calcite carbonate.

3. High safety and reliability

As no rolling bearings or screws in grinding cavity, there are no problems caused by bolts shedding or rapid wear of bearings and seal components.

4. High fineness, flexible adjustment

The final fineness of the grinding materials can be adjusted between 325 meshes and 2500 mesh (47-5 micron), and the product fineness can reach D97≤5μm.

5. Environment-friendly

The application of pulse bag filter and muffler greatly alleviates dust pollution and noise.

6. Advanced intelligent speed control device

Convenient adjust, more uniform particle size.

Main Specifications of Vermiculite Grinding Mill:

Main Specification | ||||

Model | HGM80 | HGM90 | HGM100L | HGM125 |

Ring Diameter(mm) | 800 | 900 | 1000 | 1300 |

Ring Number(layer) | 3 | 3 | 4 | 4 |

Roller Number(piece) | 21 | 27 | 36 | 44 |

Main Shaft Speed(r/p/m) | 230-240 | 200-220 | 180-200 | 135-155 |

Input Size(mm) | no more than 20 | no more than 20 | no more than 25 | no more than 25 |

Finished Size(um, mesh) | 5-47 | 5-47 | 5-47 | 5-47 |

Capacity(t/h) | 0.5-4.5 | 0.6-6.5 | 1-8.5 | 1.5-12 |

Overall Dimension(L*W *H,m) | 13.9*4*6.2 | 14.7*4.8*7.2 | 18*4.6*8.6 | 14*9*10.25 |

Motor Powder (Kw) | 123-143 | 168.35 | 243.95 | 344.4 |

- Q:I have some henchicks that have inspired me to start an indoor dish garden using other cacti or succulents what kind of soil/sand/gravel base combination should I start with?. I will be using a wide, shallow dish, like a flat bottomed ceramic dishhopefully at least 12-16 inches in diameter.and maybe only 2 or 3 inches deep.

- Buy some cactus soil and just top the soil with gravel, it keeps the sandy cactus soil from rising up when you water it and allows the water to sink in better. Be careful with your plant selection and be sure they all grow at a similar speed otherwise the faster growing plants will take over the pot and kill the very slow growing ones.

- Q:where can i get vermiculite in albuquerque NM? (:?

- Yes. Plant your cuttings in vermiculite (not plain water or they won't adapt well to solid medium) and keep them outside in the shade. Water them well until they root. Then slowly acclimate the plants to direct sunlight by first placing the plant in mottled sunlight--part shade, part sun--and eventually plant them in the soil near the original plant. Cut off the lower leaves so it will grow better. These plants are very hardy--some varieties hardier than others. Edit: Don't forget to keep the plants well watered until the root system is built up. Pinch off any blossoms until you plant them in the soil. Once in the soil, use Miracle Gro for tomatoes and put crumbled eggshells around each plant. You ought to get some good plants out of these.

- Q:I need to know what (or what kind of) stores sell perlite and vermiculite so if anyone can help me out it would really mean alot.oh, and price of each would be extremely helpful.

- I okorder

- Q:have available cocount coi, peat moss,

- sawdust would be better if you can get it.

- Q:What do i do if my beaded dragon has babies and plz tell me the thing i need if she dose have them HELP!!!!!!!

- when they burp eat their air, causes monaj

- Q:i saw on the internet dat i should use 5 - 6 inches of a mix of something and something, i 4got wat its is and i also have a question dat people tell me i shouldnt buy soil with chemicals or pesticides, wer can i buy dis? can u gimme a picture of wat it looks

- I've used spaghnum peat moss from Home Depot for years. It looks just like dirt. I have some burrowing tarantulas which I use the spaghnum mixed with sand. I moistened it slightly, and packed it down real well. My tarantulas have dug some pretty nice burrows. I can see them through the glass.

- Q:i heard that the water trays (pans) doesn‘t hold enough water to support the correct humidity at hatch time is this true and if so what do I need to put in their to raise the humidity? and please be specific and thank you!

- I develop chickens--never artificially incubated 'til this 365 days. The cautioned volume of humidity is sixty 5% or greater. The optimal is seventy 5%. (it is for chickens) yet once you have candled see the chicks coming up in the eggs your humidity fee is at a first rate fee, i would not concern approximately it b/c, through fact the previous Answerer pronounced you need to finally end up killing them. in case you prefer to, you need to spritz the eggs with water. submit to in concepts, nature isn't an exacting technological awareness my hens look to do nicely with hatching on their very own w/o the help of a thermometer or barometer. They occassionally get off the eggs to devour get some water have had no probs with hatching costs as long through fact the eggs are fertilized. sturdy success!

- Q:fiberboard,vermiculite,cellulose,or polystyrene

- You can use a magnet to take out the iron by passing it over and stirring it around the mixture. Then submerge the mixture in water to dissolve the salt then strain, and boil off the water to leave only salt. Then you could heat the remaining sand and vermiculite. Since the vermiculite should expand, you could filter/strain the sand out through a strainer.

- Q:When I repot my plants could this old soil mixed with vermiculite and perlite be dumped in the compost pit?

- The ingredients are: iron, water, cellulose, vermiculite, activated carbon and salt. When the iron is exposed to oxygen it oxidizes (rusts) releasing heat. The salt is a catalyst for this oxidation and the carbon help disperse the heat. The vermiculite is an insulator for retaining heat.

- Q:One of the plants say to place in a bag for eight weeks with 1tsp water and germination material. What is the germination material?

- There are a number of different types of germination materials. Germination material could be vermiculite, perlite, sand, a sterile seed starting mix, even water can be a growing medium for some seeds. If it's a carnivorous collection, you could use sphagnum peat, too. Didn't they provide you with a growing medium when you bought the collection?

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Vermiculite Grinding Mill of excellent quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords