VD/VOD Vacuum Ladle Refining Furnace

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

VD/VOD Vacuum Ladle Refining Furnace

40TVOD furnace

100T VD furnace

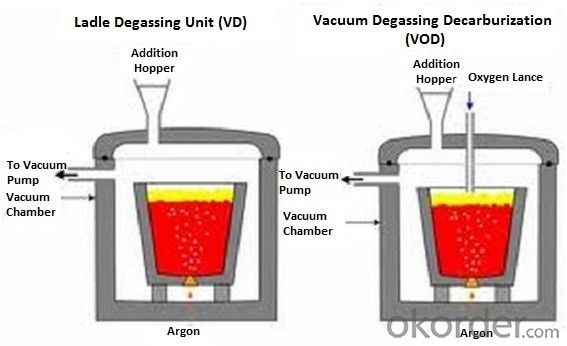

In recent years, secondary vacuum refining technique gets popular and further developed. The heart of global metallurgical industry has transferred from quantitative to be variety diversification and high quality. The super purity index ( total [H]、[N]、[O]、[S]、[P] get 50ppm,or even lower) reflects the quality of product, The effective way to achieve super purity index is secondary vacuum refining technique. There are many ways of secondary vacuum refining, the most popular ways are:1, VD- ladle vacuum refining process.2, VOD- vacuum oxygen decarburization ladle vacuum refining process.

VD/VOD ladle vacuum refining process strengthens blowing argon reasonably on the bottom of furnace; it can stir molten steel adequately and get ideal dynamics effect. If combining VD and LF, the furnace can get ideal molten steel refining temperature with easy structure and low cost. Both of the above process can dehydrogenize, denitrify, desulfurize, deoxidize under vacuum conditions and get the function of Vacuum Oxygen Decarburization (VOD) to achieve the purpose of refining super pure steel.

Vacuum pump system is the main equipment of vacuum refining device. Base on our ten years experience of test research and generalized application, two series products – “Full steam jet vacuum pump system” and “Steam jet + water ring vacuum pump system” had formed. “Full steam jet vacuum pump series” uses a certain pressure water steam and cooling water as working medium of the pump, “Steam jet +water ring vacuum pump system” uses a certain steam pressure, less water steam and cooling water as working medium, and consume few electricity. The steam consumption of “Full steam jet vacuum pump” is relative high, and need to equip with bigger boiler, but the cost of vacuum pump itself is lower. The steam consumption of “Steam jet +water ring vacuum pump system” is relative low, and can equip with a smaller boiler, but the vacuum equipment itself costs higher. So the total investment cost of above system is basically consistent, both are satisfied the requirement of producing molten steel by secondary vacuum refining.

Our company is a Key enterprise and professional manufacturer of steam jet vacuum pump and whole vacuum equipments in China, and we are also the first corporation of designing and producing VD/VOD Vacuum refining equipment and VC Vacuum Cast Equipment in China. Up to now, we had designed and produced more than 180 sets VD/VOD, RH vacuum refining equipment, VC vacuum casting equipment for more than 100 companies. All these equipments meet the requirements of design and well received by the end user.

- Q:What is the difference between industrial furnaces and boilers?

- A boiler is a mechanical device for heating water into hot water or steam by the use of heat from fuel or other sources of energy. The original meaning of a pot is a water container heated by fire. The furnace is the place where the fuel is burned. The boiler includes two parts, the cooker and the furnace.

- Q:What is an industrial furnace pit?

- The creation and development of industrial kilns play an important role in the progress of mankind. Chinese appeared more perfect in the Shang Dynasty copper smelting furnace, furnace temperature is up to 1200 DEG C, up to 0.8 meters in diameter kiln stove.

- Q:What are the advantages of a vacuum furnace?

- High degree of integration of mechanical and electrical. On the basis of the improvement of temperature measurement and control accuracy, the workpiece movement, air pressure regulation, power adjustment can be programmed in advance, and quenching and tempering are carried out according to the steps.

- Q:How to use industrial furnace equipment?

- If it is water cooling furnace door, but also to ensure the smooth flow of pipes, winter pipes are not frozen. When the boiler is in a limited position, the interlocking device for cutting off the power supply shall be provided when the furnace is in and out, and the number of broken wires in the pitch of the steel wire shall not exceed 10%, and the counterweight of the furnace door shall be reliably hung.

- Q:Why does the burner of industrial furnace burn occasionally?

- The general process for burner ignition, blowing furnace, electric spark ignition, solenoid valve, open the gas in case of delayed spark ignition, detection device detects the flame, the controller accepts signal so that the solenoid valve open, gas continuous normal combustion. However, if the ignition fails or the burner fires, the detector cannot detect the flame, which causes the solenoid valve to close and the burner flameout.

- Q:What are the companies in the world that are currently engaged in metallurgical furnaces?

- Basically, no industrial furnace manufacturer can do all types of stoves.Often associated with the industry is very large,so your ranking is basically meaningless.

- Q:Brief introduction to repair of industrial furnace

- Compared with other equipment, industrial furnace repair has many characteristics: more repair times, more maintenance costs, more non-standard equipment and unsafe factors.

- Q:Selection of heat preservation material for industrial furnace

- In the neutral and oxidizing atmosphere, the tensile strength, toughness and fiber structure can be maintained for long term use. The temperature is 950-1400 centigrade. Excellent chemical stability; excellent thermal stability; excellent tensile strength; low thermal conductivity; low thermal capacity; excellent sound absorption and noise reduction performance.

- Q:What are the combustion equipments used in industrial boilers?

- The boiler is an energy conversion equipment. The energy input to the boiler has the chemical energy and the electric energy in the fuel. The boiler outputs steam with certain heat energy and high temperature water.

- Q:How many kinds of industrial electric furnaces are there?

- Industrial furnace according to the heating mode is divided into two categories: one is the fuel furnace, combustion heat with solid, liquid or gaseous fuel in the furnace for heating the workpiece; the second is in the furnace, the furnace converts electrical energy to heat the heat.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

VD/VOD Vacuum Ladle Refining Furnace

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products