various kinds of plastic formworks newly used

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Main Introduction of Plastic Formwork:

More and more people in the world would like to importPlasticformwork from China since recentyears. Plastic formwork is a new type construction material in the construction industry andpeople could buy good quality at a very good price from Chinese market. In this way, the distributors make more profit and the end users could save more cost. Before you decide to purchase this kind of plastic formwork, you need to know how plastic formwork sprung up and grasped the market.The biggest panel is 120x60cm, weight only 10.5kg, which can be lift and set up by only one person easily, need no crane on the site.

2. The Advantages of Plastic Formwork:

1:easy set up

Different size of panels can be firmly locked by simply turn the special handles to 90 degree. The panels have rib on the back, which makes the

system need not traditional wood blocks and nails. The panels have holes to fit tie rod, guarantee the strength of the whole system.

2:modularity

Modular formwork composed by different size of panels, the main item is 120x60 panel, the size is 120x60cm, which used for the large area of walls

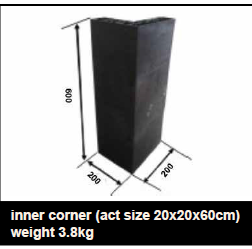

and slabs. There are also small size of panels like 10x60 panel (10x60cm), 20x60 panel (20x60cm), 25x60 panel (25x60cm), inner corner (20x20x60cm) and outer corner (10x5x60cm). Due to the variety of panel size, the system can form almost all size walls120x60 panel (act size 120x60cm) of multiple by 5cm. The material of modular formwork is PC-ABS mixied with special glass fibres which enable panels to hold high pressures.

3:strength

The handles are made by high strength Nilon, each panel locked by at least 4 handls, which makes the whole system strong enough to pour 40cm walls.

4:friendly

The system need not cut and nail due to the variety size, and nearly need no wood, the material can be recycled after broken, will not pollute the enviroment.

5:consequent

Concrete does not stick to plastic, thus the panels need no oil before using, and can be cleaned simply by water. The surface of the wall which built by modular formwork is smooth, can be left without rework.

4. FAQ of Plastic Formwork

1) What can we do for you?

We can ensure the quality of the vinyl banner and avoid extra expenses for customers.

.We can provide you the professional design team.

.We can provide fashionable and newest styles for you.

.We can design the artwork for you.

. Please feel free to customize.

2) What promises can be done by us?

. If interested in plastic formwork, please feel free to write us for any QUOTE.

. If printing required, please advise asap because the whole set need much more time to complete.

. Please DO check goods when courier knocks your door and contact us asap if any issue.

- Q:How does steel frame formwork improve the quality of concrete?

- There are several ways in which the quality of concrete is improved by steel frame formwork. To begin with, the use of steel frame formwork ensures that the concrete maintains its shape and form throughout the curing process, thanks to its stable and rigid structure. This prevents any deformation or warping, resulting in a final product that is more accurate and precise. Furthermore, the steel frame formwork allows for easy and efficient placement of reinforcement bars within the concrete. This is crucial for enhancing the structural integrity and strength of the concrete. By providing a secure framework, the steel frame holds the reinforcement bars in place, preventing displacement or movement during pouring and curing. In addition, steel frame formwork enables precise control over the pouring of the concrete, ensuring a consistent and uniform distribution of the mixture. This eliminates any voids or air pockets, resulting in a final product that is denser and more durable. Moreover, the use of steel frame formwork creates a smooth and even surface for the concrete, reducing the need for additional finishing or surface treatments. This not only saves time and resources but also improves the overall aesthetics of the concrete. In summary, steel frame formwork is essential for improving the quality of concrete by providing stability, facilitating the placement of reinforcement bars, allowing for precise pouring, and creating a smooth surface finish.

- Q:Are there any disadvantages to using steel frame formwork?

- Yes, there are some disadvantages to using steel frame formwork. Firstly, steel frame formwork can be more expensive to purchase or rent compared to other types of formwork systems. Additionally, steel frame formwork is heavier and bulkier, making it more difficult to transport and handle on construction sites. Furthermore, steel frame formwork requires skilled labor for assembly and disassembly, which may add to the overall construction costs. Finally, steel frame formwork may not be suitable for curved or irregularly shaped structures, limiting its versatility in certain construction projects.

- Q:What are the key quality control measures for steel frame formwork installation?

- There are several key quality control measures that should be followed for steel frame formwork installation. These measures are crucial to ensure the structural integrity and safety of the formwork system. 1. Proper inspection: Before starting the installation process, it is important to thoroughly inspect the steel frame formwork. This includes checking for any damages, defects, or missing components. Any issues should be addressed and resolved before proceeding with the installation. 2. Accurate alignment: The steel frame formwork should be properly aligned to ensure that it fits together seamlessly and provides a stable structure. This includes checking the vertical and horizontal alignment of the components, as well as ensuring that they are level and plumb. 3. Secure connections: The connections between the steel frame formwork components should be secure and tight. This can be achieved by using appropriate fasteners, such as bolts or screws, and ensuring that they are properly tightened. Loose connections can lead to instability and compromise the integrity of the formwork system. 4. Level and flat surfaces: The surfaces of the steel frame formwork should be level and flat to provide a stable and uniform support for the concrete. This can be achieved by using leveling tools, such as spirit levels or laser levels, to ensure that the formwork is properly aligned and adjusted. 5. Reinforcement placement: If reinforcement bars are required in the formwork system, they should be properly placed and secured. This includes ensuring that the bars are correctly positioned and adequately supported to prevent displacement during the concrete pouring process. 6. Adequate bracing: Steel frame formwork should be adequately braced to provide stability and prevent any deformation or collapse. This can be achieved by using diagonal braces or stiffeners, as well as ensuring that all bracing components are properly secured and tightened. 7. Regular inspection and maintenance: Throughout the installation process, regular inspections should be conducted to identify any potential issues or defects. Any damages or defects should be repaired or replaced immediately to ensure the safety and effectiveness of the formwork system. By following these key quality control measures, the steel frame formwork installation can be carried out efficiently and effectively, resulting in a robust and reliable structure for concrete casting.

- Q:Can steel frame formwork be used for the construction of power plants?

- Yes, steel frame formwork can be used for the construction of power plants. Steel frame formwork is a versatile and robust system that provides excellent strength and stability, making it suitable for large-scale construction projects such as power plants. It allows for the creation of precise and complex formwork shapes required for various structural elements, including walls, columns, beams, and slabs. The use of steel frame formwork in power plant construction offers several advantages. Firstly, it ensures accurate and consistent dimensions, resulting in high-quality concrete structures. This is particularly crucial in power plants, where structural integrity and durability are of utmost importance due to the heavy machinery and equipment involved. Additionally, steel frame formwork allows for faster construction cycles, as it can be easily assembled and disassembled, allowing for rapid progress and efficient use of time and resources. It also offers flexibility in terms of formwork design modifications, accommodating changes or adaptations that may arise during the construction process. Furthermore, steel frame formwork possesses excellent load-bearing capabilities, making it suitable for constructing large-scale power plant structures. It can withstand the weight and pressure exerted by heavy equipment, pipes, and other components commonly found in power plants. In conclusion, steel frame formwork is a viable option for the construction of power plants. Its strength, versatility, and efficiency make it an ideal choice for creating precise and durable formwork structures required for power plant construction.

- Q:Are there any environmental benefits to using steel frame formwork?

- Using steel frame formwork in construction projects brings several environmental benefits. Firstly, steel is a highly durable material that maintains its structural integrity even after multiple uses. This means that steel formwork can be employed for various construction projects, reducing the need for new formwork materials and minimizing waste generation. Moreover, steel frame formwork can be easily dismantled and reassembled, making it adaptable and versatile for different construction needs. Additionally, steel is a recyclable material, meaning that it can be recycled and transformed into new steel products at the end of its life cycle. This helps reduce the demand for new steel production and the associated environmental impacts, such as mining and energy consumption. Furthermore, steel frame formwork contributes to energy efficiency in construction. Its superior strength and load-bearing capacity allow for the construction of more slender and lightweight structures. As a result, less material is used overall, leading to energy savings during manufacturing, transportation, and installation processes. In conclusion, opting for steel frame formwork offers a range of environmental benefits, including durability, reusability, recyclability, and energy efficiency. By choosing this construction method, projects can minimize waste generation, conserve resources, and reduce their environmental footprint.

- Q:What are the considerations for selecting the appropriate formwork spacing?

- There are several factors that need to be taken into account when choosing the appropriate formwork spacing. To begin with, the type and size of the formwork material play a significant role. Different materials have varying load-bearing capacities, so it is crucial to select a spacing that can adequately support the weight of the poured concrete. Furthermore, the size of the formwork panels also affects the spacing. Larger panels may require closer spacing to prevent sagging or bowing. The height of the formwork is another important consideration. As the height increases, the spacing between supports may need to be decreased to ensure stability and prevent excessive deflection. This is especially important in taller structures where external forces like wind can introduce additional stresses on the formwork. The concrete mix design and pouring technique should also be taken into account. If a high-slump concrete mix is used, it may exert greater pressure on the formwork, necessitating closer spacing to prevent bulging or blowouts. Likewise, if a fast-setting or self-consolidating concrete is being used, the formwork spacing must be chosen to accommodate the rapid pouring and setting process. The expected loads during the construction process must also be considered. If heavy equipment or machinery will be used near the formwork, closer spacing may be necessary to provide extra support and prevent damage. Additionally, the presence of rebar or other reinforcing elements within the concrete should be factored in, as they can increase the load on the formwork and require tighter spacing. Lastly, safety is a crucial aspect when determining formwork spacing. Sufficient spacing should be chosen to allow workers to safely access and maneuver around the formwork. This includes considering the space required for tools, equipment, and proper bracing or scaffolding. In conclusion, the selection of appropriate formwork spacing requires careful consideration of factors such as formwork material, height, concrete mix design, expected loads, and safety requirements. By taking these considerations into account, the formwork can provide the necessary support and stability for successful concrete construction.

- Q:How does steel frame formwork handle different types of formwork curing techniques?

- Steel frame formwork is highly versatile and can effectively handle different types of formwork curing techniques. The steel frame provides stability and strength, allowing for various curing methods such as air curing, water curing, and chemical curing to be easily implemented. Additionally, the adjustable nature of steel formwork allows for precise control over the curing process, ensuring the desired level of strength and durability in the final concrete structure.

- Q:What are the main components of steel frame formwork?

- The primary elements of steel frame formwork are as follows: 1. Steel Frames: These serve as the fundamental components of steel frame formwork. They are crafted from top-notch steel and are engineered to provide stability and support while pouring concrete. The frames are typically modular and can be easily assembled and disassembled, making them incredibly versatile. 2. Plywood Panels: Plywood panels are utilized to construct the formwork surface onto which the concrete is poured. These panels are usually composed of high-quality plywood treated to be resistant to water and durable. The dimensions and thickness of the plywood panels may vary depending on the specific project requirements. 3. Tie Rods and Wing Nuts: Tie rods and wing nuts are employed to hold the steel frames together and ensure the stability of the formwork structure. The tie rods are threaded and can be adjusted to achieve the desired tension, while the wing nuts are used to secure the tie rods in place. 4. Adjustable Props: Adjustable props are employed to support the steel frame formwork and ensure that it maintains the correct position during the concrete pouring process. These props can be easily adjusted to the desired height and can withstand heavy loads. 5. Formwork Accessories: Various accessories such as clamps, connectors, and brackets are employed to connect and reinforce the steel frames. These accessories aid in ensuring the stability and integrity of the formwork structure. Overall, the primary components of steel frame formwork collaborate to create a robust and dependable system capable of supporting the weight of the concrete throughout the construction process. This type of formwork is widely utilized in the construction industry due to its durability, flexibility, and user-friendly nature.

- Q:Are there any limitations to the size or shape of structures that can be constructed using steel frame formwork?

- Steel frame formwork has limitations in terms of the size and shape of structures that can be constructed. Although it is a versatile construction method, there are certain constraints to consider. Firstly, the size of the steel frames themselves is a limitation. These frames come in standard sizes and dimensions, and the structure being built must adhere to these specifications. If a project requires non-standard dimensions, customization or modifications may be necessary, resulting in increased costs and construction time. Moreover, the weight-bearing capacity of the steel frame formwork is another limitation. The steel frames have a maximum load capacity that must be respected to ensure structural integrity and safety. Depending on the design and purpose of the structure, as well as the weight of the materials used and the expected loads, the size and spacing of the steel frames may need to be adjusted accordingly. Additionally, the shape of the structure is a factor that limits the use of steel frame formwork. This construction method is well-suited for rectangular or square structures, as it can easily accommodate straight lines and right angles. However, if a project requires complex or irregular shapes, additional measures such as custom-made formwork or extra support structures may be necessary to achieve the desired design. To sum up, steel frame formwork has its advantages in construction, but it is important to consider the limitations in terms of the size and shape of structures that can be built using this method. These limitations arise from the standard sizes and load-bearing capacity of the steel frames, as well as the challenges in accommodating unconventional dimensions or complex shapes.

- Q:How does steel frame formwork provide support to the concrete structure?

- Steel frame formwork provides support to the concrete structure by acting as a temporary mold or framework that holds the wet concrete in place until it hardens and gains sufficient strength. The steel frame formwork ensures that the concrete is poured and set in the desired shape and dimensions, providing stability and preventing any deformation or collapse during the curing process.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

various kinds of plastic formworks newly used

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords