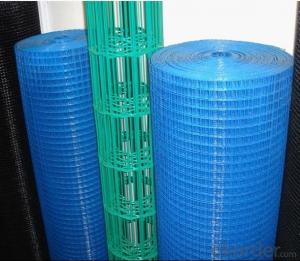

Vapor-liquid Filter Editor Foam Fishing Net

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 roll

- Supply Capability:

- 30000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Description of Vapor-liquid filter editor

Vapor-liquid filter editor (the vapor-liquid network, also known as foam fishing net, woven wire mesh), is a special form of woven wire mesh, it is the production of wire mesh demister, oil separator, dust, environmental protection the main components of the engine noise, mechanical damping, etc. used in the project, but also in the automotive industry, the electronics industry has been widely used.

Specification of Vapor-liquid filter editor

Wire diameter size range: 0.08 ~ 0.3mm of flat wire or round wire. Single-strand braided, multi-strand braid, metallic and non-metallic wire filament (various fibers) weaving, may be needed in the wire-line press rolled into a variety of styles of specifications corrugated, such as "man" herringbone pattern.

2 common vapor-liquid filter specification editor type specifications

Standard 40-10060-150 105-300140-400 160-400200-570

-Efficient 60-100 80-10080-150 90-150150-300 200-400300-600

High wear type 20-100 30-15070-400 100-600170-560

Damping 33-3038-40 20-4026-40 30-4030-50 48-5030-60 30-8050-120

HG / T21618-1998 wire mesh demister Used for gas-liquid filter specifications are: SP, DP, HR, HP-type four standard specifications. Used screen demister gas-liquid filter

specifications are: HG5-1404, HG5-1405, HG5-1406, standard number for the Shanghai Q / SG12-1-79. Standards set forth in the three types of gas-liquid network, namely standard, efficient and high-penetration type. For users of all kinds of non woven mesh, such as multi-strand, eds., Various shapes of gaskets, bushings, etc. We can be customized according to the thickness of the mesh size and wire diameter.

The features of Vapor-liquid filter editor

Three gas-liquid filter parameter editing a silk warp range: 0.10mm-0.55mm (through a common wire: 0.20mm-0.25mm) In addition, a number of strands twisted together weave.

2, hole size: from (2 × 3mm) to (4 × 5mm) and then to (12 × 6mm) Also according to customer requirements for fine-tuning the hole size. Openings in the form of macropores and orifices cross arrangement (aperture size in the longitudinal direction is the same, the width is not the same)

3, the surface condition of liquid filters: the flat-type mesh and pressed into corrugated corrugated mesh (width and depth of the corrugations have different specifications)

4, the gas-liquid filter width: 40mm, 80mm, 100mm, 150mm, 200mm, 300mm, 400,500mm, 600mm and the like.

5, the main gas-liquid filter material: stainless steel wire have AISI201,202,301,302,304,304L, 321,316,316L, pure nickel wire, titanium wire, Monel, galvanized wire, to Roberts, stainless steel silk and cotton, or plastic, PP, PC, PE, PVC, PTFE.

Application of Vapor-liquid filter editor

Mainly used for processing demister for droplet separation of gas inside. May also be extruded, for the manufacture of filtration devices.

FAQ

1. Payment term: T/T, L/C, Western Union

2. Payment terms: 30% by T/T should be paid in advance, the balance payment paid againest the copy of B/L

3. Delivery time: shipping products within ten days, or negotiate according to total quantity.

4. Min order quantity: 50 pieces, or by negotiate with each other

Our Services

Inquiry response: Your inquiries will be replied in 24hours

Sample support: Free samples are available in 3-5days

- Q:Screen printing and screen printing plate on the photosensitive material What are the requirements

- posters, business cards, binding cover, product signs and printing and dyeing textile and other silk screen pollution process first plate production The use of ink in the developer is the production of ink bucket cleaning is to produce cleaning waste or waste wipe

- Q:What is the screen printing plate?

- Silk cloth is generally the quality of domestic and imported polyester is far worse.

- Q:Is the screen printing the best way? And other printing methods than it?

- Screen printing is the most adaptable in all printing methods. Ink layer thickest, good hiding power, the best durability, full of bright graphics, other printing methods can not be replaced. Generally used for outdoor advertising, transfer flower paper, electronic lines, glass cloth and other special industries

- Q:Screen printing and printing the difference

- ink, pressure and other processes, so that ink transferred to paper, fabric, Leather and other materials on the surface, the bulk copy of the original content of the technology.

- Q:How to make screen printing layout smooth

- Paint the (pattern) paint, repeat it several times and check that the pattern is transparent. If the number of prints is not large, the back generally do not need to paint.

- Q:What is the principle of screen printing?

- When printing, the ink through the mesh of the mesh on the substrate to re-form graphics / text.

- Q:Screen printing, how to print circular arc surface

- If the ink transferred to the cup on the lighter, it may be necessary to add ink, or produce blocking network.

- Q:How to get the correct fishing wire

- under the net, I would like to you like the same line, the river is not urgent, then you can stop the river, the river is urgent, then the water, remember not to lose, and then is waiting, the middle can also use a bamboo pole and the like Pick up the net to receive fish, are generally put there for several hours.

- Q:Screen printing has several characteristics

- Which forms an image or a text, and the transcript is printed as the easiest stencil, starting at the end of the 19th century. This printing is done on a specially made stencil, made of a typewriter or a pencil,

- Q:Screen printing ink firmness problem

- Screen printing rarely use water-based ink, because the water-based ink in the non-absorbent substrate adhesion fastness is usually much worse than the solvent-based ink, plus silk ink layer thick, adhesion is more problematic.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Vapor-liquid Filter Editor Foam Fishing Net

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 roll

- Supply Capability:

- 30000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords