Vapor Barrier Membrane with Aluminum Foil Coated

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Vapor Barrier Membrane with Aluminum Foil Coated

Introduction:

Vapor insulation membrane is a roof membrane with three-layers, which is specially designed for application on ventilated pitched roofing, can be used under bituminous membrane as a extra protection for the attic insulation. It includes PET/PP non-woven fabric layer, PE/PP woven layer and aluminum foil layer. The three-layers structure ensure extreme resistance to tearing. Furthermore, the special stabilization additives ensure 3-month resistance to UV radiation.

Specification:

Chemical Composition | PP & PE, Aluminum Foil, Woven Fabric |

Roll Size | 1.5meter*50meter |

Density: | 60gsm~130gsm |

Tensile Strength | MD:150N/50mm; CMD:115N/50mm |

Waterproofing Rate | W1 |

Vapor Resistant Rate | 6.9g/m2 ▪ 24h |

Aging rate under hot circumstance (90℃*168h) | MD:90%; CMD:100% |

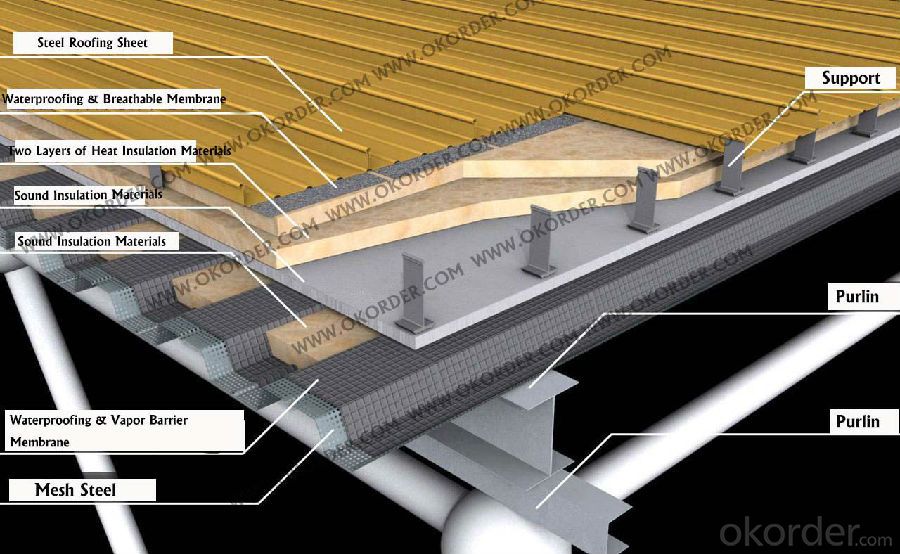

Typical Installation

Typical Application:

FAQ:

1. Where is your factory located in?

Our factory is located in Jiangsu province, close to Shanghai.

2. Have you ever been export?

Yes, our product has been exported to many countries.

3. Can we get samples?

Yes, we are free for samples, what you need to assume is freight charge.

- Q:Bathroom first leveling or do waterproof, what is the difference

- 7. The threshold stone is only decorated, do not mistakenly believe that can hold water. In short, each process have to carefully do not leave a hidden trouble to ensure worry. But the reality of the structure, materials, workers, mutual protection and many other unsatisfactory, so that waterproof is a common problem, perhaps set (overall) bathroom by the factory as a whole production test, on-site assembly will solve this common problem.

- Q:How do you make waterproofing in the kitchen and bathroom?

- Fatty acid cement mortar waterproofing agent; integrated current domestic and foreign new waterproof material of the latest technology, in the original polymer cement mortar waterproofing agent developed on the basis of raw materials imported from Germany, the higher fatty acid materials, by more than 20 kinds of raw materials by the special complex Chemical reaction of water-based emulsion, a new type of fatty acid cement mortar waterproofing agent.

- Q:Slope roof drains do not need to be waterproof

- The overall rigid waterproof layer is often due to these small structural nodes handled properly, resulting in the failure of the entire roof waterproof.

- Q:How can the toilet waterproof works fail?

- Can only do a new waterproof, and now have engaged in the base of the waterproof coating, the effect is very good. It is best to ask professionals to do their own difficult.

- Q:Do you use the waterproof material on the building to be harmful to the human body?

- Your pores, the respiratory tract, the lungs, will be hurt, when young do not feel out, the consequences more powerful than smoking.

- Q:There is no formaldehyde in the finished putty

- Visible putty powder and formaldehyde or a great relationship, but now many manufacturers have introduced environmentally friendly putty powder, not only environmentally friendly pollution-free important is also can control the air, there is a negative ion putty powder is the composition which contains tourmaline tourmaline, through And the water molecules in the air combined with the decomposition of negative ions to deal with the air, anion can be neutralized with formaldehyde into dust falling into the air, you can also remove the dust in the air, as well as enhance the metabolism of the function.

- Q:I would like to ask how to do in the warm water above,

- I do not do 80% of the warm water, of course, the use of good quality water pipes, waterproof water is generally done in the following to do, if done in the warm tube above will affect the heat of the floating, to warm the following covered with a Layer insulation layer and then covered with warm tube to, and then beat the water to ensure that no leakage. And finally in the above covered with wooden floor or floor tiles.

- Q:Hello, roof with SBS waterproof material bulk density is how much?

- As the SBS coil finished with pure asphalt is not the same, the coil includes a variety of surface material weight. The following is the different types and different thickness of the SBS coil unit area weight, due to the need to lap and pave the reinforcement layer, calculate the load in the following unit area weight, the general multiplied by 1.2 coefficient.

- Q:What should you pay attention to before the construction of the basement waterproofing membrane?

- 3, painting the bottom line: for the reasonable arrangement of the daily pavement workload, must first on the basis of the program according to set the program to draw a good dividing line, the entire track and field into pieces, and then press the block by pavement. In order to ensure smooth drainage and less joints and other requirements, the use of the first outer ring after the construction process.

- Q:What is the car material so that the car can be waterproof, in the rain will not leak in?

- ?C. metal technology and other: metal technology refers to the aluminum plate and other metal plate through the machine to suppress the concavity and convex surface, and then made of metal paint color, and finally after grinding, drawing and other production of the car stickers (car standard); Area can not be too large, can only be used for a small range of iconic car stickers.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Vapor Barrier Membrane with Aluminum Foil Coated

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords