Valve with Competitive Price from Valve Manufacturer

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Gate Valve Description:

A gate valve, also known as a sluice valve, is a valve that opens by lifting a round or rectangular gate/wedge out of the path of the fluid. The distinct feature of a gate valve is the sealing surfaces between the gate and seats are planar, so gate valves are often used when a straight-line flow of fluid and minimum restriction is desired. The gate faces can form a wedge shape or they can be parallel. Gate valves are primarily used to permit or prevent the flow of liquids, but typical gate valves shouldn't be used for regulating flow, unless they are specifically designed for that purpose. Because of their ability to cut through liquids, gate valves are often used in the petroleum industry. For extremely thick fluids, a specialty valve often known as a knife valve is used to cut through the liquid. On opening the gate valve, the flow path is enlarged in a highly nonlinear manner with respect to percent of opening. This means that flow rate does not change evenly with stem travel. Also, a partially open gate disk tends to vibrate from the fluid flow. Most of the flow change occurs near shutoff with a relatively high fluid velocity causing disk and seat wear and eventual leakage if used to regulate flow. Typical gate valves are designed to be fully opened or closed.When fully open, the typical gate valve has no obstruction in the flow path, resulting in very low friction loss.

2. Main Features of the Gate Valve:

• Valve body cavity using non-toxic epoxy resin,both inside and outside flashboard completely is coated with rubber

• Free of water pollution

• High manufacturing accuracy

• High strength

• Environmental protection and energy saving

• Good visual effect

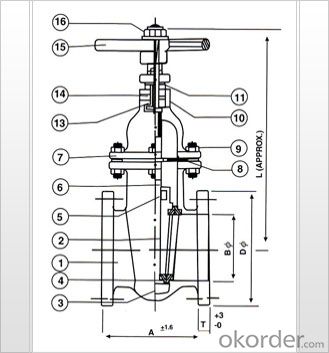

3. Images

4. Gate valve Specification

5.FAQ

1. What's are the characteristics of gate valve?

The distinct feature of a gate valve is the sealing surfaces between the gate and seats are planar, so gate valves are often used when a straight-line flow of fluid and minimum restriction is desired. The gate faces can form a wedge shape or they can be parallel.

2. What is the work principle of gate valve ?

The gate faces can form a wedge shape or they can be parallel. Gate valves are primarily used to permit or prevent the flow of liquids, but typical gate valves shouldn't be used for regulating flow, unless they are specifically designed for that purpose. Because of their ability to cut through liquids, gate valves are often used in the petroleum industry.

3. What is the structure?

Bonnets provide leakproof closure for the valve body. Gate valves may have a screw-in, union, or bolted bonnet. Screw-in bonnet is the simplest, offering a durable, pressure-tight seal. Union bonnet is suitable for applications requiring frequent inspection and cleaning. It also gives the body added strength. Bolted bonnet is used for larger valves and higher pressure applications.

- Q:What are the definitions of internal, external and leakage valves?

- Outside leakage generally refers to the valve and connecting flange or threaded connection between the seal and guide...

- Q:Which valves are used in the power station?

- Water supply system: butterfly valve, gate valve, eccentric hemisphere valveOil and gas system: stainless steel ball valve, stop valveFire fighting system: gate valve, relief valve, relief valve, sprinkler system

- Q:How to check if the gas valve is open?

- The valve handle and pipe as "one" word proved to come, as "ten" word is off. Another simple way is to turn clockwise and turn counterclockwise..Chasing the answerThe valve handle and pipe as "one" word proved to come, as "ten" word is off. Another simple way is to turn clockwise and turn counterclockwise..The valve handle and pipe as "one" word proved to come, as "ten" word is off. Another simple way is to turn clockwise and turn counterclockwise..The valve handle and pipe as "one" word proved to come, as "ten" word is off. Another simple way is to turn clockwise and turn counterclockwise..

- Q:What does the "Z45T-16" valve mean?

- Z - gate valve4 - flange connection5 - Dark pole, stem non lifting (gate valve structure)T - copper alloy, valve sealing face code16 - pressure code, 1.6MPaMaterial code for grey cast iron valves of nominal pressure less than or equal to PN16 shall be omitted in model preparation.May refer to JB/T 308 valve model compilation method

- Q:What should be checked before using the valve?

- The valve must be tested before installationI. examination of documentsThe valve must check the quality documents before installation, the valve manufacturer should be nameplate, nameplate and the body should be the name of the manufacturer, valve type, nominal pressure, nominal diameter and logo, must comply with the "universal valve logo" GB 12220.Two, appearance inspection

- Q:What does valve DN50/80 mean?

- DN refers to the nominal diameter unit mm, that is, the diameter of the pipe. DN 5080 is the diameter of 50mm 80mm

- Q:Symbols for all types of valves

- Look at the attachment I gave you. The legend of the valves is complete!

- Q:What valves are needed on the construction site?

- Order valves1, according to the use of place, use, and understand the relevant laws and regulations, specifications, standards, policies, approval may be used after the selection of valves suitable for various requirements;2, confirm the working conditions of valve, applicable medium, working pressure and medium temperature;3, determine the nominal diameter corresponding to the pipe: DN (mm), NPT, NPS (");4, determine the way to connect with the pipe: flange type, internal (external) thread type, welding type, clamp type, clamp type, card sleeve type, etc.;5, determine the valve operation mode of driving: manual, worm gear drive, pneumatic, electric, hydraulic, electromagnetic, electro hydraulic, etc.;6, confirm the types of valves: gate valve, globe valve, throttle valve, plunger valve, ball valve, butterfly valve, diaphragm valve, plug valve, check valve, safety valve, drain valve, pressure reducing valve and other special valves;7, determine the use of valves: switching type, adjustment type, safety type and so on;8, determine the valve shell and internal parts of the material: carbon steel, alloy steel, stainless steel, ductile iron, gray cast iron, copper alloy, aluminum alloy, plastic and so on;9, determine the valve sealing performance requirements, sealing level or sealing leakage;10, determine the valve coating requirements, packaging requirements, transportation requirements;11, special needs of the valve should also be determined: structure length, valve height, appearance size, flow resistance, emission capacity, flow characteristics, protection level, explosion-proof performance and other parameters;12, determine the valve installation position and posture.

- Q:How can the material be checked by valve approach? What experiments do you need?

- (8) the throttle valve does not test the tightness of the closing parts, but the strength test and the tightness test of the stuffing and the gasket shall be carried out.(9) the pressure test, the valve closing force only allows a person's normal physical strength to close; not augmented with tools like leverage (except torque wrench), when the hand wheel diameter is greater than the wait at 320mm, allowing two common off.(10) with a sealed valve, should be taken out of packing for sealing test, sealed after the official closed, check whether leakage. When gas is used as a test, check the water in the stuffing box. When sealing test is carried out, the upper seal is not allowed to be in the tight position.(11) when the valve with drive device is tested and its tightness is tested, the sealing test shall be carried out by using the driving device to close the valve. For manual drive units, seal test shall also be done with the actuating closing valve.(12) the by-pass valve installed on the main valve after the strength test and the sealing test. The strength and tightness test of the main valve is carried out. The main valve should be opened when the closing member is opened.(13) iron valve strength test, the application of Pratia tapping valve and valve cover, check whether there is any leakage.(14) the valve test, in addition to the provisions of the plug valve to allow sealing surface oiling, other valves are not allowed in the sealing surface of the oil test.(15) when the valve pressure test, the blind plate on the valve pressure should not be too large, so as to avoid deformation of the valve, affecting the test results (cast iron valve if pressed too tight, will be damaged).(16) after the valve test pressure, should promptly remove the water and clean the valve, should also be prepared for the test record.

- Q:What is the valve before and after the pump?

- Conventional setting, the pump is installed before and after the cut-off valve. As for the check valve, according to the need to decide whether to install, to see whether the occasion required to prevent backwater function.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Valve with Competitive Price from Valve Manufacturer

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords