Valve with Competitive Price from Valve Manufacturer on Sale

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Gate Valve Description:

A gate valve, also known as a sluice valve, is a valve that opens by lifting a round or rectangular gate/wedge out of the path of the fluid. The distinct feature of a gate valve is the sealing surfaces between the gate and seats are planar, so gate valves are often used when a straight-line flow of fluid and minimum restriction is desired. The gate faces can form a wedge shape or they can be parallel. Gate valves are primarily used to permit or prevent the flow of liquids, but typical gate valves shouldn't be used for regulating flow, unless they are specifically designed for that purpose. Because of their ability to cut through liquids, gate valves are often used in the petroleum industry. For extremely thick fluids, a specialty valve often known as a knife valve is used to cut through the liquid. On opening the gate valve, the flow path is enlarged in a highly nonlinear manner with respect to percent of opening. This means that flow rate does not change evenly with stem travel. Also, a partially open gate disk tends to vibrate from the fluid flow. Most of the flow change occurs near shutoff with a relatively high fluid velocity causing disk and seat wear and eventual leakage if used to regulate flow. Typical gate valves are designed to be fully opened or closed.When fully open, the typical gate valve has no obstruction in the flow path, resulting in very low friction loss.

2. Main Features of the Gate Valve:

• Valve body cavity using non-toxic epoxy resin,both inside and outside flashboard completely is coated with rubber

• Free of water pollution

• High manufacturing accuracy

• High strength

• Environmental protection and energy saving

• Good visual effect

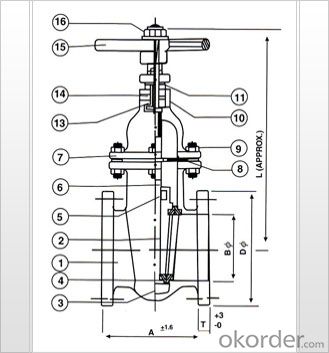

3. Images

4. Gate valve Specification

5.FAQ

1. What's are the characteristics of gate valve?

The distinct feature of a gate valve is the sealing surfaces between the gate and seats are planar, so gate valves are often used when a straight-line flow of fluid and minimum restriction is desired. The gate faces can form a wedge shape or they can be parallel.

2. What is the work principle of gate valve ?

The gate faces can form a wedge shape or they can be parallel. Gate valves are primarily used to permit or prevent the flow of liquids, but typical gate valves shouldn't be used for regulating flow, unless they are specifically designed for that purpose. Because of their ability to cut through liquids, gate valves are often used in the petroleum industry.

3. What is the structure?

Bonnets provide leakproof closure for the valve body. Gate valves may have a screw-in, union, or bolted bonnet. Screw-in bonnet is the simplest, offering a durable, pressure-tight seal. Union bonnet is suitable for applications requiring frequent inspection and cleaning. It also gives the body added strength. Bolted bonnet is used for larger valves and higher pressure applications.

- Q:What does 3/4''mean in the name of the valve?

- 3/4''is the valve diameter, said 20MM, inches, equivalent to DN20 of the valve, is also said to be the 6 interface we say old foreman

- Q:What is called protective valve, and other valves what is the difference?

- Protection valve should be in the air defense valve, can be copper gate valve. (according to the specific use of civil air defense requirements, design institute does not count).2, while the protection valve should be a locking device with the valve, not the general valve can be replaced.

- Q:What is a lift rod valve?

- The valve stem and valve plate are relatively fixed, and the valve stem rises up when the valve plate is raised

- Q:What does 1/2 mean in valve specification?

- 1/2 is American Standard, said 1/2. Equivalent to GB DN15, nominal diameter 15mm, indicating that the diameter of the pipe is 15mm. In the plumbing industry, it's called 4 points.Valve specifications in common use:Say: American Standard - GB4 points - 1/2 - DN156 points - 3/4 - DN201 inches - 1 - DN251 inches 2 - 1 and 1/4 - DN321 and a half - 1 and 1/2 - DN402 inches - 2 - DN50

- Q:Z11H/Y forged steel gate valves H/Y what does that mean?SZ45H S what do you mean?Blow 2Z41YGY-40P, what do you think?What does NKZ61H vacuum valve NK mean?What does DS/Z64H water seal valve DS mean?Specific valve number how to see ah, detailed information, thank you!

- Structure of code structure of code seal vertical plate type single eccentric sealing type 0 single eccentric center 5 vertical plate 1 6 2 7 three double eccentric double eccentric eccentric 3 three eccentric 7 linkage 4 linkage 9 structure of code structure of code lifting straight through 1 swing single type 4 vertical more than and 2 petal angle 5 type 3 dual valve type 6 butterfly valve 7 Table 9 check valve structure of code the sealing surface and lining material code, in accordance with the provisions of table 10. Table 10 the sealing surface of the valve seat sealing surface or liner material code or liner material code sealing surface or lining material code or code of lining material tin based bearing alloy seal (Babbitt) B Monel M alloy T enamel C nylon plastic rubber X N steel boriding nitriding steel D P hard alloy Y fluorine plastic lining F lead Q ceramic G austenitic stainless steel R Cr13 stainless steel H S note: the plastic body directly processed seat sealing surface material code with "W". When the sealing surface of the sealing material is not the same, the material name is indicated by the material with low hardness. The value of the nominal pressure of 10 times, according to the number of MPa (1MPa=106Pa). The valve body material code represented by the letter, in accordance with the provisions of table 11. Table 11 the valve body material body material material code code code C chromium nickel molybdenum stainless steel R Cr13 stainless steel H S plastic steel chromium molybdenum copper and copper alloy I T malleable cast iron titanium and titanium alloys K A L Aluminum Alloy CrMoV V Cr Ni stainless steel P Z gray cast iron ductile iron Q. In the original standard of nominal pressure equal to or less than 1.6MPa gray cast iron and the nominal pressure is greater than or equal to 2.5MPa carbon steel valve omitted the code.

- Q:What is the choice of pneumatic valve or electric valve for ultrafiltration inlet control valve?

- Now the UF system is basically full automatic system, that is to choose automatic valve. As for the pneumatic valve or electric valve, depending on your investment and the scene.

- Q:How to open the gas valve with drawings

- First of all, you have to determine the direction of the valve opening, usually homeopathy, it is off, the reverse is open. First: to determine the opening of the valve, are generally ball valve, screw 90 degrees on it. Second. At the top of your house, there is a button that can be pulled out.

- Q:The valve is rusty and can not be opened. What shall I do?

- Spray with rust removing agent on the rusty rotating parts of the valve. Then use an afterburner to make a tentative rotation. Open it and turn it in the opposite direction. And then spray rust remover. Repeat this several times, and the valve will probably open. Seriously rusty valve, if it really can not open, simply replace it.

- Q:What's the valve as a unit?

- Business now there are many valve manufacturers, with the rapid expansion of SMEs, SMEs are more ~!

- Q:What does the valve "4" mean?

- This is an inch inch size, 4 inches =1/2 = 25.4mm = 12mm

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Valve with Competitive Price from Valve Manufacturer on Sale

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches