User-friendly Ppr Pipe for Water Convanyance with High Quality and Good Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Overview

The comprehensive technical performance and economic indicator of PP-R are much better than galvanized pipe, UPVC pipe, polyethylene-aluminum compound pipe, PE-X (cross-linked polyethylene) and polybutylene pipe etc. For this reason PP-R is the leading products and widely used for feed-water piping in developed countries in Europe and America.

Application

1) Cold and hot water supply systems for civil and industrial constructions, e.g. in residential buildings, hospitals, hotels, school and office buildings, ship building

Irrigating system for gardens and green houses

2) Public and sport facilities such as swimming pools and stadiums

3) For rainwater utilization systems.

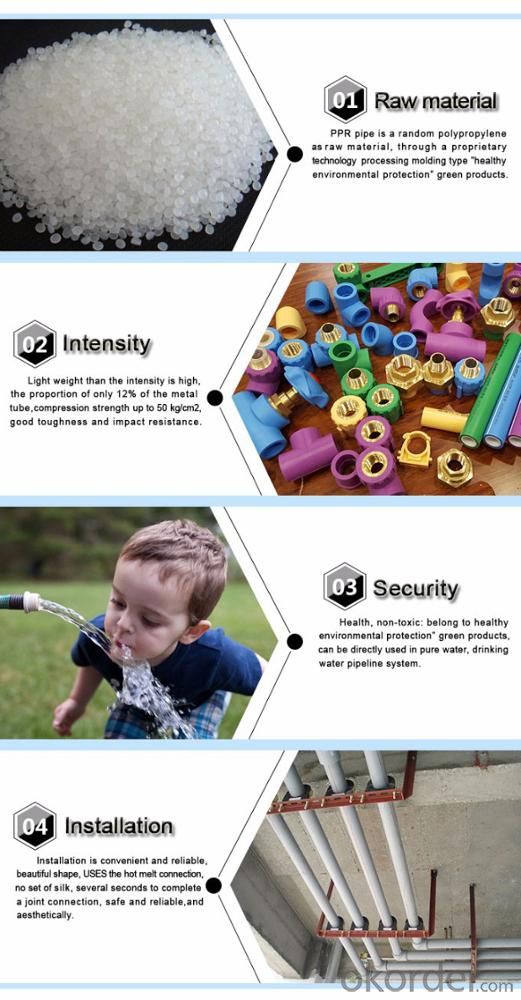

Advantages

1.No leakage ,pressure PN 10-16;

2.Well and high quality control ;

3.Environment friendly, non-toxic, good looking and long service life;

4.Light weight, easy to handle and transport;

5.Soft colors and excellent design, suitable for in stellation either exposed or hidden;

6.Wonderful ability in chemical corrosion resistance;

7.Easy and fast installation, making cost minimized;

8.Widely used in building, irrigation, industry and swimming pool;

9.Small order acceptable ;

10.Customer's design and logo are welcome.

Product Description

Pressure | Size(mm) | Pressure | Size(mm) |

PN1.25MPA | 20*2.0 |

PN1.6MPA | 20*2.3 |

32*2.9 | 32*3.6 | ||

40*3.7 | 40*4.5 | ||

50*4.6 | 50*5.6 | ||

90*8.2 | 90*10.1 | ||

110*10.0 | 110*12.3 |

Shipment/Payment

Packing: 5.8m/11.8m each piece. 50m/100m/150m/200m for small sizes pipes.

Loading port: China port(Chongqing port, Shanghai port, Tianjin port)

Price term we offer: FOB,CIF,CFR

Payment: L/C and T/T

Product Show

FAQ

- Q:What are the manufacturing processes of plastic pipe fittings?

- The draft tube is preheated and the vacuum setting pump is opened at the same time. The vacuum pump is used to adjust the discharge volume of the sizing sleeve.

- Q:Are plastic pipe fittings suitable for use in greenhouses?

- Yes, plastic pipe fittings are suitable for use in greenhouses. They are lightweight, durable, and resistant to corrosion, making them an ideal choice for irrigation systems and other plumbing needs in a greenhouse environment. Additionally, plastic fittings are easy to install, affordable, and can handle the varying temperatures and humidity levels commonly found in greenhouses.

- Q:Can plastic pipe fittings be used for irrigation systems in cold climates?

- Yes, plastic pipe fittings can be used for irrigation systems in cold climates. Plastic fittings, such as PVC or polypropylene, are commonly used in irrigation systems due to their durability, affordability, and resistance to corrosion. They can withstand freezing temperatures if the system is properly installed and drained before winter. Additionally, plastic fittings are less prone to cracking or bursting compared to metal fittings when exposed to extreme cold.

- Q:How do you remove a plastic pipe fitting?

- To remove a plastic pipe fitting, you can follow these steps: 1. Turn off the water supply: Before removing any pipe fitting, it is essential to turn off the water supply to prevent any leaks or accidents. 2. Prepare the area: Clear the surrounding area of any obstructions or debris that may hinder your work. 3. Identify the type of fitting: Determine the type of plastic fitting you are dealing with. Common types include compression fittings, push-to-connect fittings, or threaded fittings. 4. Compression fittings: For compression fittings, you will need two adjustable wrenches. Use one wrench to hold the fitting in place while using the other wrench to turn the nut counterclockwise until it comes off. 5. Push-to-connect fittings: Push-to-connect fittings typically have a release mechanism built into them. Locate the release collar near the fitting, then push it down firmly towards the pipe while pulling the pipe away from the fitting. This will release the connection. 6. Threaded fittings: Threaded fittings require the use of a pipe wrench or adjustable wrench. Place the wrench on the fitting's body or hex section and turn it counterclockwise to loosen and remove the fitting. 7. Inspect and clean: Once the fitting is removed, inspect the pipe and fitting for any damage or debris. Clean the pipe end and the inside of the fitting to ensure a proper connection when reinstalling it or replacing it with a new fitting. Remember to exercise caution and follow safety guidelines when working with plumbing systems. If you are unsure or encounter any difficulties, it is advisable to consult a professional plumber.

- Q:Can plastic pipe fittings be used for swimming pool plumbing systems?

- Yes, plastic pipe fittings can be used for swimming pool plumbing systems. Plastic fittings, such as PVC or CPVC, are commonly used in pool plumbing due to their durability, resistance to chemicals and corrosion, and ease of installation. These fittings are designed to withstand the water pressure and chemicals typically found in swimming pools, making them a suitable choice for pool plumbing systems.

- Q:How do you connect plastic pipe fittings?

- To connect plastic pipe fittings, you typically use solvent cement specifically designed for plastic pipes. First, ensure the pipe ends are clean and free from debris or burrs. Then, apply a generous coat of solvent cement to both the outside of the pipe and the inside of the fitting. Insert the pipe fully into the fitting, giving it a slight twist to evenly distribute the cement. Hold the joint together firmly for a few seconds to allow the cement to set. Finally, let the joint cure for the recommended time before applying any pressure or testing the connection.

- Q:Can plastic pipe fittings be used for agricultural irrigation systems?

- Yes, plastic pipe fittings can be used for agricultural irrigation systems. Plastic fittings are commonly used in these systems due to their durability, corrosion resistance, and ease of installation. They are also cost-effective and can withstand the harsh conditions associated with agricultural irrigation, such as exposure to chemicals and varying weather conditions.

- Q:Can plastic pipe fittings be used for underground installations?

- Yes, plastic pipe fittings can be used for underground installations. Plastic pipe fittings, such as those made from PVC or polyethylene, are commonly used in underground applications due to their durability and resistance to corrosion. These fittings are designed to withstand the soil and environmental conditions typically encountered underground, making them a suitable choice for various underground installations like water supply systems, drainage systems, and irrigation systems.

- Q:Can plastic pipe fittings be used in septic tank systems?

- Yes, plastic pipe fittings can be used in septic tank systems. Plastic fittings are commonly used in septic tank systems due to their durability, resistance to corrosion, and ease of installation. They are also cost-effective and compatible with different types of pipes commonly used in septic systems.

- Q:PE copper wire mesh plastic composite pipe connection in several ways?

- Should be wire mesh, plated with copper, fused welding, flange connection, but also hot melt butt.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

User-friendly Ppr Pipe for Water Convanyance with High Quality and Good Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords