Unilateral Formwork Support System

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

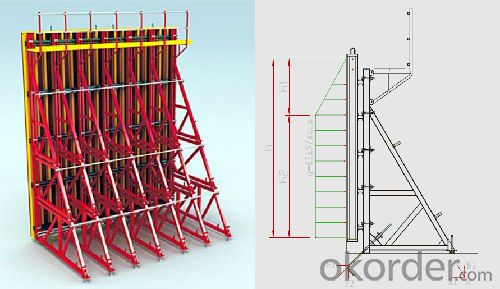

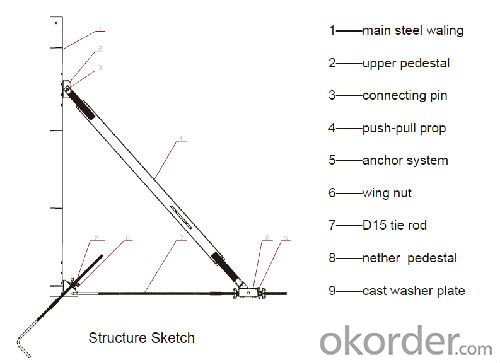

1. Structure of Unilateral Formwork

Unilateral bracket is composed of embedded parts system part and the frame body is composed of two parts, including:The system includes embedded parts: anchor bolt, nut, connecting the outer-link, the outer nut and beams.

According to your requirements of the project selection frame height has the following two kinds of specifications: H=3600 standard section, section H=3200 height.

2. Main Features of Unilateral Formwork

◆ For concrete heights up to 8.0m and a fresh concrete pressure up to a maximum of 60KN/m2.

◆ Good standard performance and versatility.

◆ Fast element coupling, all units can be quickly connected.

◆ The finished wall is excellent and absolutely waterproof.

◆ Optimized sizes for transportation.

3. Unilateral Formwork Images

4. Unilateral Formwork Specification

5. FAQ of Unilateral Formwork

1) What can we do for you?

We can ensure the quality of the Unilateral Formwork and avoid extra expenses for customers.

We can provide you the professional design team.

We can provide fashionable and newest styles for you.

We can design the artwork for you.

Please feel free to customize.

2) What promises can be done by us?

If interested in Unilateral Formwork, please feel free to write us for any QUOTE.

If printing required, please advise asap because the whole set need much more time to complete.

Please DO check goods when courier knocks your door and contact us asap if any issue.

3) What about of our after-sale service?

Response will be carried out in 24hours after receiving any complain or request.

If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

Packing: As Customer's Requirements

Shipping: We have various shipping ways for our customers, such as express which including TNT, DHL, FEDEX, UPS, EMS, etc. ; by air/ sea, and we are VIP of these express.

Shipping time:Normally small orders, it just 10-15 business days to arrive your hand; When comes to the customs declaration, it may need 7 days. Other mass qty of Unilateral Formwork, we send them out by sea or by air to sea port or air port to save some shipping freight for our customers. By ocean, it may need 45~60days, by air, it may need 25~40days.

- Q:Roof plate support combination structure

- Xingmin Albert Construction Equipment Co., Ltd. is the only one since the product research and development - mold development - processing - pipe - rolling - stamping - cold bending - casting - welding - forming - surface treatment, such as the whole process of production enterprises, Min Wai Yip Group.

- Q:What is the meaning of the template bearing surface elevation in the bridge specification?

- Elevation refers to the distance from a point along the vertical line to the absolute base plane, said the absolute elevation, referred to as the elevation. The distance from a point along a vertical line to a hypothetical quasi-base surface is assumed to be an elevation.

- Q:A load that can be sustained by a fastener

- The requirements of the construction template are calculated according to the area of the contact surface between the concrete and the template, and then the template coefficient (empirical) which is not in contact with the concrete is taken into consideration in consideration of the loss of the template, the turnover turnover and the turnover.

- Q:Main and vice keel upgrade modification - the new building template support birth opportunity

- Deputy keel directly on the main keel, and the use of the same method of wood, easy to operate. The vice keel is designed for opening, reducing the weight, reducing your costs, and facilitating connection to the template when the bearing capacity is allowed

- Q:The amount of material is 70.66M2, the height of 5.2M plate thickness 120MM then its template to support the amount of high project is the amount of more than 3.6 meters per 1 meter per meter to calculate the template to support the high project I know, Asked how the template to support the high amount of how to get the project.

- The mold is stable, the structure is well-structured, the spacing of the bracket is arranged rationally, and the back ribs of the stent are set to meet the requirements of strength, stiffness, locality. Stability requirements. Internal mold with a special easy to unload the steel mold to ensure that the size of the construction of accurate, solid support.

- Q:How is the identification of tall template works?

- [2009] No. 87 provides more than 5 meters of the template support project for the more dangerous sub-project, more than 8 meters for more than a certain size of the larger dangerous sub-project.

- Q:Scaffolding structure template support frame type

- According to the horizontal structure of the situation: 1) horizontal structure layer is not set or a small set of diagonal bar or shear support frame; 2) 1 or several horizontal reinforcement layer set the support frame In addition, single double row support frame (Such as brackets) and not set the points, the latter's support height should not be greater than 4m. Support frame load is generally vertical load, but the box-based template (wall template) support frame at the same time by Vertical and horizontal loads.

- Q:Unilateral support basement wall waterproof protective layer do not do it? Will there be a broken ring on the waterproofing membrane? Is it possible to destroy the process?

- If you want to do without protective layer, you can look at the United States permanent condensate DPS + infiltration crystallization film series waterproof material. Water-based infiltration crystalline inorganic waterproof material, completely penetrate into the concrete inside, do not find leveling layer, can be sprayed directly. Do not keep, sprinkle, etc. Impermeability level can reach S 11 level or more. Completely inorganic material will not be aging. There is no delamination problem. If the repair, supporting the use of US permanent condensate RMO can.

- Q:Template support did not stand good, how to remedy the lower floor?

- First measured how much sink ah, the plate elevation measured first, and then find the design, such a thing is not you can decide, the design may be looking for experts, if the lower 10 to cm it does not matter. But also the size of the kanban, if you say 4 * 4 little problem.

- Q:Foundry boutique building foundation · New type of shear wall template support

- In view of the above problems, Changli Tianjian developed and improved the new shear wall template support system, using a cold rolled steel made of retractable vertical beams and different specifications of the beam (0.6,0.9,1.2,1.5,1.8,2.4 m). The vertical beam can be freely stretched between 2.6 and 3.0 meters (available according to customer requirements). The beams are docked through 0.9 and 1.2 m fittings, which fundamentally solve the problems of wall width and wall height. problem.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Unilateral Formwork Support System

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords