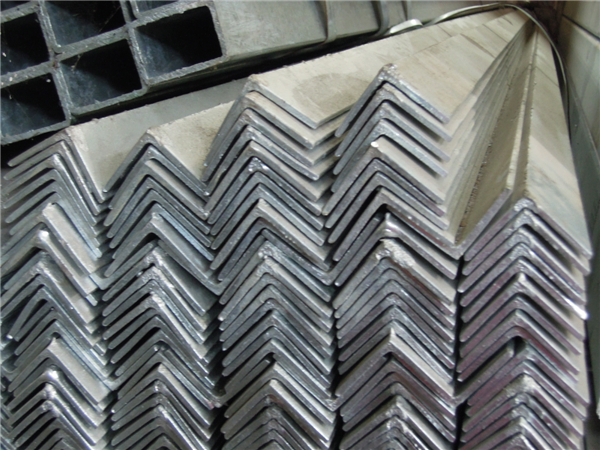

Unequal Leg and Unequal Thickness Angle Steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 PCS

- Supply Capability:

- 450000 PCS/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel Name: Angle steel,Steel angle

Type of Angles:Unequal leg and unequal thickness angle steel

Unequal leg and unequal thickness angle steel Main steel grades: S355JR,Q345B,St52-3,S235JR,A283 Grade C,A36,

St372,Q235B,SS400,A,B,AH32,AH36

Steel standard: JIS G3192,GB 9788-88

Main application:Unequal Leg and Unequal Thickness Angle Steels are used to build ship and vessels and other steel structures

Unequal Leg and Unequal Thickness Angle Steel Rolling range: Equal-leg angles 75*75*6mm-250*250*35mm,Unequal-leg angles 100*75*7mm-200*100*16mm,unequal leg and unequal thickness angles 200*90*9*14mm-450*125*11.5*18mm.

Unequal Leg and Unequal Thickness Angle Steel Surface Treatment: Hot rolled and Coated or Shot blasting and painting

Unequal Leg and Unequal Thickness Angle Steel Supply Ability: 50000 Tons per month

Unequal Leg and Unequal Thickness Angle Steel Additional service:Shot blasting and painting,Cutting and welding as per user’s request.

- Q:How is steel used in the manufacturing of communication towers?

- Steel is commonly used in the manufacturing of communication towers due to its strength, durability, and flexibility. It provides the necessary structural support to withstand extreme weather conditions and support the weight of antennas and other equipment. Additionally, steel's malleability allows for easy customization and modification of towers to meet specific height and design requirements.

- Q:What are the different types of steel fasteners and their applications?

- There are several types of steel fasteners commonly used in various applications. Some of the most popular ones include screws, bolts, nuts, and washers. Screws are versatile and can be used in woodworking, metalworking, and general construction. Bolts are often used for heavy-duty applications, such as in machinery or structural installations. Nuts are paired with bolts to secure objects together, while washers provide a smooth surface and distribute pressure. Additionally, there are specialized fasteners like rivets and anchors that serve specific purposes in industries like aerospace and construction.

- Q:What are the different types of steel products used in the manufacturing of luxury goods?

- Some of the different types of steel products commonly used in the manufacturing of luxury goods include stainless steel, Damascus steel, and carbon steel.

- Q:How does steel sheet metal cutting and punching work?

- Steel sheet metal cutting and punching work by using various tools and techniques to remove material from the steel sheet. Cutting can be done through shearing, which involves applying a high force to a small area, or by using plasma or laser cutting methods. Punching, on the other hand, involves creating holes or shapes in the sheet by using a punch and die set. Both cutting and punching processes require precise control and machinery to ensure accurate and clean results.

- Q:What are the different types of steel sheet and plate materials?

- There are several different types of steel sheet and plate materials, including carbon steel, stainless steel, alloy steel, and galvanized steel. These materials vary in their properties and are used for different applications based on their strength, corrosion resistance, and durability. Carbon steel is a common choice for its affordability and versatility, stainless steel is known for its resistance to corrosion and high temperature, alloy steel offers improved strength and toughness, and galvanized steel is coated with zinc to prevent rusting.

- Q:How is steel billet produced?

- Steel billet is produced through a process called continuous casting, which involves melting scrap steel in an electric arc furnace and then pouring the molten steel into a water-cooled mold. As the steel cools, it solidifies into a semi-finished rectangular shape called a billet, which can be further processed into various steel products.

- Q:What are the applications of steel plates?

- Steel plates have a wide range of applications, including construction of buildings, bridges, and roads, manufacturing of machinery and equipment, shipbuilding, and automotive industry. Additionally, they are used in the energy sector for building power plants and pipelines, as well as in the aerospace industry for manufacturing aircraft components.

- Q:What are the advantages of using steel in automotive manufacturing?

- There are several advantages to using steel in automotive manufacturing. Firstly, steel is a strong and durable material, providing excellent structural integrity and enhancing the overall safety of vehicles. Additionally, steel is readily available and cost-effective, making it a cost-efficient choice for mass production. Moreover, steel can be easily shaped and molded, allowing for complex designs and customization options. Lastly, steel has a high melting point and is resistant to extreme temperatures, ensuring the longevity and reliability of automotive components.

- Q:How is steel tubing used in the oil and gas industry?

- Steel tubing is used in the oil and gas industry for a variety of purposes such as drilling, production, and transportation. It is used as casing and tubing in oil wells to provide structural support and prevent the collapse of the wellbore. Steel tubing is also used for transporting oil and gas from the well to the surface, as well as for various equipment and infrastructure in oil and gas processing facilities.

- Q:How are steel products used in the railway industry?

- Steel products are extensively used in the railway industry for various applications. Steel is commonly used for manufacturing railway tracks, train wheels, and various structural components of the railway infrastructure. Additionally, steel is used in the construction of railway cars, locomotives, and various equipment such as bridges, tunnels, and signaling systems. Its high strength, durability, and ability to withstand heavy loads make steel an ideal material for ensuring the safety and efficiency of the railway system.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Unequal Leg and Unequal Thickness Angle Steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 PCS

- Supply Capability:

- 450000 PCS/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords