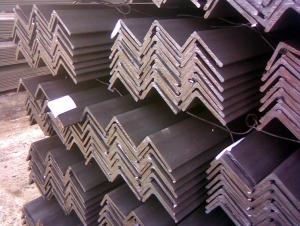

Unequal Angle

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Stainless Steel Angles

1.Grade: SS200,300,400 series

2.Size: 25×25×3 mm-100×100×10mm

3.Process: HRAP

4. Length: 2-6m

5. Shape: Equal

6. Delivery: within 20 days

7. MOQ: 1 ton

8. Certificate: ISO 9001:2008, SGS

9. Package:Standard Export Packing, or put into wooden boxes according to your

requirement

10. Application: Construction, Marine, Industry and so on

Name | Stainless Steel Angles | ||||||

Standard | ASTM A554, A312, A249, A269 and A270 | ||||||

Material Grade | 304,316,201,202, 316L,430 | ||||||

Length | 6m or as customers' request | ||||||

Tolerance | a) thickness: +/-0. 15mm | ||||||

| |||||||

b) Length:+/-4. 5mm - 0mm | |||||||

Surface | 180G, 320G, 400G Satin / Hairline(Matt Finish, Brush, Dull Finish) 400G, 500G, 600G or 800G Mirror finish | ||||||

Application | Decoration construction, upholstery, industry instruments | ||||||

Test | Squash test, Extended test, Water pressure test, Crystal rot test, Heat treatment, NDT | ||||||

Chemical Composition of Material |

Composition

Material | 201 | 202 | 304 | 316L | 430 | |

C | ≤0.15 | ≤0.15 | ≤0.08 | ≤0.08 | ≤0.12 | ||

Si | ≤1.00 | ≤1.00 | ≤1.00 | ≤1.00 | ≤1.00 | ||

Mn | 5.5-7.5 | 7.5-10 | ≤2.00 | ≤2.00 | ≤1.00 | ||

P | ≤0.06 | ≤0.06 | ≤0.045 | ≤0.045 | ≤0.040 | ||

S | ≤0.03 | ≤0.03 | ≤0.030 | ≤0.030 | ≤0.030 | ||

Cr | 16-18 | 17-19 | 18-20 | 16-18 | 16-18 | ||

Ni | 3.5-5.5 | 4-6 | 8-10.5 | 10-14 |

| ||

Mo |

|

|

| 2.0-3.0 |

| ||

Mechanical Property | Material Item | 201 | 202 | 304 | 316L | ||

Tensile Strength | ≥535 | ≥520 | ≥520 | ≥520 | |||

Yield Strength | ≥245 | ≥205 | ≥205 | ≥205 | |||

Extension | ≥30% | ≥30% | ≥35% | ≥35% | |||

Hardness (HV) | <253 | <253 | <200 | <200 | |||

- Q:How do steel angles contribute to the sustainability of a project?

- Steel angles contribute to the sustainability of a project in several ways. Firstly, they are made from recycled steel, reducing the demand for new raw materials and promoting a circular economy. Secondly, steel angles have a high strength-to-weight ratio, allowing for lighter and more efficient structural designs, which in turn reduces the amount of steel required and minimizes the carbon footprint of the project. Lastly, steel angles are durable, resistant to corrosion, and have a long lifespan, ensuring the longevity and sustainability of the structure they support.

- Q:How do you reinforce a steel angle?

- Depending on the specific application and requirements, there are various ways to reinforce a steel angle. Here are a few commonly used techniques: 1. Welded Plates: To enhance the strength of a steel angle, welded plates can be added at critical points. These additional plates are typically made of the same or stronger steel and are welded to the flanges or web of the angle. This method improves the overall rigidity and load-bearing capacity of the angle. 2. Gusset Plates: An alternative effective method for reinforcing a steel angle involves using gusset plates. These plates usually have a triangular shape and are welded to the flanges or web of the angle. By distributing forces more evenly across the angle, gusset plates increase its strength and resistance to bending or twisting. 3. Bracing: Bracing is a technique that involves adding extra steel members to reinforce a steel angle. These members can be directly connected to the angle or attached using welded or bolted connections. Bracing effectively enhances the angle's resistance to lateral or torsional forces and improves its overall stability. 4. Composite Materials: In certain cases, composite materials can be utilized to reinforce a steel angle. Fiber-reinforced polymers (FRPs) or carbon fiber reinforced polymers (CFRPs) can be wrapped around or bonded to the angle, providing added strength and stiffness. These composite materials significantly enhance the angle's load-carrying capacity and resistance to corrosion. To determine the most suitable method for reinforcing a steel angle in a specific application, it is essential to consult a structural engineer or a professional with expertise in steel structures. The chosen reinforcement technique must take into account the expected loads, the angle's geometry, and the desired level of reinforcement.

- Q:Can steel angles be used for storage rack systems?

- Yes, steel angles can be used for storage rack systems. Steel angles are commonly used in the construction of storage rack systems due to their strength and durability. They provide structural support and stability to the racks, allowing them to withstand heavy loads and provide a safe and efficient storage solution. Steel angles can be easily fabricated and installed, making them a popular choice for storage rack systems in various industries such as warehouses, manufacturing facilities, and retail stores. Additionally, steel angles can be customized to meet specific storage requirements, such as adjusting the height or width of the racks. Overall, steel angles are a reliable and cost-effective option for storage rack systems.

- Q:Can steel angles be used as supports for mechanical or electrical equipment?

- Yes, steel angles can be used as supports for mechanical or electrical equipment. Steel angles are versatile and strong, making them suitable for a wide range of applications. They can provide stability, rigidity, and support to hold mechanical or electrical equipment in place. The L-shaped design of steel angles allows for easy attachment and installation, making them convenient for various mounting needs. Additionally, steel angles can be easily customized and fabricated to meet specific requirements, ensuring a secure and reliable support system for the equipment.

- Q:How does the price of steel angles vary based on size and grade?

- The price of steel angles can be affected by various factors, including the size and grade of the steel. When it comes to the size, larger angles are generally more expensive than smaller ones. This is because larger angles require more raw material and involve more manufacturing processes, resulting in higher production costs. As a result, as the size or length of the angle increases, so does its price. The grade of the steel also plays a role in determining the price. Steel angles come in different grades, each with its own characteristics and properties. Higher-grade steel angles, such as stainless steel or structural steel, tend to be more expensive compared to lower-grade options like mild steel. This is because higher-grade steels often require more advanced manufacturing techniques and superior quality raw materials, which contribute to higher production costs and, consequently, a higher price. Other factors that can impact the price of steel angles include market demand, the availability of raw materials, and manufacturing efficiency. Fluctuations in demand and supply can lead to price variations, with higher demand usually resulting in higher prices. Additionally, the availability and cost of raw materials used in the production of steel angles, such as iron ore and scrap metal, can affect the overall price. Lastly, advancements in manufacturing processes and technology can increase efficiency, potentially lowering production costs and influencing the final price of steel angles. To summarize, the price of steel angles is influenced by their size and grade. Larger angles and higher-grade steels tend to be more expensive due to increased production costs. Market demand, raw material availability, and manufacturing efficiency also play a role in determining the price of steel angles.

- Q:Can steel angles be used in conveyor systems?

- Yes, steel angles can be used in conveyor systems. Steel angles are commonly used in conveyor systems to provide structural support and stability. They can be utilized to create the framework for the conveyor system, including the conveyor bed, side frames, and supports. Steel angles are known for their strength and durability, making them an ideal material for handling heavy loads and withstanding the continuous movement and impact that conveyor systems experience. Additionally, steel angles can be easily welded or bolted together, allowing for flexibility in designing and customizing conveyor systems to meet specific requirements. Overall, steel angles are a popular choice in conveyor system construction due to their reliability, versatility, and cost-effectiveness.

- Q:Can steel angles be used for building frames?

- Yes, steel angles can be used for building frames. They are often used as structural elements in construction due to their strength and versatility. Steel angles provide stability and support to building frames, making them a popular choice in the construction industry.

- Q:Can steel angles be used in marine applications?

- Yes, steel angles can be used in marine applications. Steel angles are commonly used in the construction of ships, offshore platforms, and other marine structures due to their high strength and durability. They provide structural support and help distribute the weight and stress of the marine environment. Steel angles are resistant to corrosion, especially when coated with protective coatings or galvanized. However, it is important to select the appropriate grade of steel angle that is specifically designed for marine applications to ensure optimal performance and longevity in harsh saltwater environments.

- Q:What are the common welding techniques for steel angles?

- Some common welding techniques for steel angles include: 1. Shielded Metal Arc Welding (SMAW): Also known as stick welding, SMAW is a popular technique for welding steel angles. It involves using a consumable electrode coated in flux, which creates a protective shield around the weld pool. SMAW is versatile and can be used for various thicknesses of steel angles. 2. Gas Metal Arc Welding (GMAW): This technique, also known as MIG welding, uses a continuous wire electrode and a shielding gas, typically a mixture of argon and carbon dioxide. GMAW offers high welding speeds and good control over the weld pool, making it suitable for welding steel angles. 3. Flux-Cored Arc Welding (FCAW): Similar to GMAW, FCAW uses a continuous wire electrode, but instead of a shielding gas, it utilizes a flux-filled wire. This flux creates a protective gas shield when heated, preventing contamination of the weld. FCAW is ideal for outdoor welding or in windy conditions. 4. Gas Tungsten Arc Welding (GTAW): Also known as TIG welding, GTAW uses a non-consumable tungsten electrode and a shielding gas, usually argon. GTAW is a precise and clean welding process that produces high-quality welds on steel angles. It is commonly used for thin steel angles or when aesthetics and control are crucial. 5. Submerged Arc Welding (SAW): SAW is a semi-automatic or automatic welding process that involves feeding a continuous wire electrode and a granular flux into the weld zone. The flux covers the weld, preventing atmospheric contamination. SAW is often used for thicker steel angles and provides high deposition rates. It is important to choose the appropriate welding technique based on the specific requirements of the steel angle joint, such as thickness, joint design, and desired weld quality. Additionally, proper preparation, including cleaning and preheating if necessary, is essential to ensure successful welds on steel angles.

- Q:Can steel angles be used for stair treads?

- Yes, steel angles can be used for stair treads. Steel angles provide structural support and stability, making them a suitable choice for stair treads. They can be easily installed and offer durability and resistance to wear and tear, making them ideal for high-traffic areas such as stairs.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Unequal Angle

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords