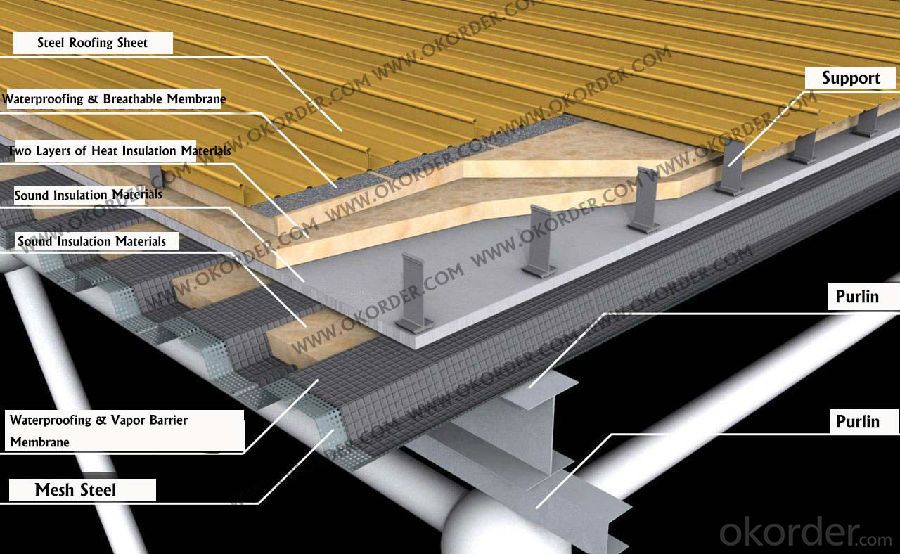

Underlay Membrane Water resistant and Vapor breathable

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Breathable Membrane PP Non-woven Fabric Laminated with PE Film

General Information:

We are located in National Development Zone in Nantong, with 22000 square meters area, including 7000 square meters dust free workshop.

We have equipped the most advanced pp non-woven production line and composite production lines including extrusion lamination production, hot melt lamination production line, calendar bonded production line with the technology from Italy and Germany, printing production line, cutting production line. We specialize in producing waterproof and breathable materials and heat insulation materials, pp non-woven fabric, disposable medical products, packaging materials and so on.

Specifications:

Product Name | Composite PP Non-Woven Roofing Breathable Waterproof Membrane |

Color | Grey |

Structure | PP Non-Woven/PE Film/PP Non-Woven |

Roll Width(m) | 1.5m (+/-0.5%) |

Roll Length(m) | (1)50m,100m,200m,500m,1000m (2)according to the customers' requirements |

Basic Weight | 80g/m²,90g/m²,100g/m²,115g/m² ,120g/m² ,140g/m² ,160g/m² |

Temperature Resistance | -40 °C to 100 °C |

Water Resistant | Class 1 |

SD-Value | 0.02m |

Vapor Permeability | 2250g/m²/24h |

UV Resistant | 3-6 months |

Packing | 1)each roll packed by plastic bag, then with carton or pallets 2)according to the customers' request |

Price Terms | FOB,CNF,CIF |

Payment Terms | TT,LC, |

Delivery Time | within 15 working days after received your payment in advance |

Typical Application:

Container Loading:

FAQ:

1. Where is your factory located in?

Our factory is located in Jiangsu province, close to Shanghai.

2. Have you ever been export?

Yes, our product has been exported to many countries.

3. Can we get samples?

Yes, we are free for samples, what you need to assume is freight charge.

- Q:How do you make waterproofing in the kitchen and bathroom?

- Kitchen and toilet is a relatively stable part of the home improvement structure, it is recommended to do waterproof mortar waterproofing agent on it, mortar waterproofing agent not only with the base surface bonding firm, and puncture resistance, high strength, waterproof life and construction Material with the life, the construction of relatively waterproof coating is also relatively simple.

- Q:Villa roof leakage what general reasons, what materials to remedy

- First, the roof leak to find the first leak, looking for the main leak from the roof to the lower to find leakage. First look at the roof there is no crack, the original waterproof layer is not aging, the roof of the original waterproof membrane has no bubbles, there are bubbles to prove that the water has entered the bottom of the waterproof layer, and thus leaking, and roof On the gutter there is no clogging.

- Q:Slope roof drains do not need to be waterproof

- The overall rigid waterproof layer is often due to these small structural nodes handled properly, resulting in the failure of the entire roof waterproof.

- Q:Roof leakage, what materials do the best waterproof

- Treatment is: large cracks available plugging the king, a small crack can be used to fill the glass glue, repair with a wall waterproofing agent, after spraying a few words on it. As the external walls of cracks and cracks need high-altitude operations, the public must ask the professional construction team to deal with, to prevent accidents. Roof leakage what materials: available SBS modified asphalt - polyester film coil, polyester film SBS-3mm, laying the coil. Roof waterproofing membrane, in addition to SBS modified asphalt, there are three EPDM coil, neoprene. Can also use architectural ointment, cement, polyurethane coating. You can also use asbestos net also do waterproof. If the cement roof cracks, I suggest you use cf-2000 efficient composite waterproofing agent. In the concrete like scraping putty scraping 5mm thick again, you can play a waterproof repair function. Can also slot repair.

- Q:Nanning building waterproof material market where

- This depends on what you need packaging materials, and if it is some packaging rope or paper or process raw materials and other different materials to find a different place, generally sold outside the packaging is more like Nanning near the train station Or the trading market,

- Q:There is no formaldehyde in the finished putty

- The current status of the market to buy regular manufacturers out of semi-finished products putty and formaldehyde has nothing to do, because the status quo countries also hit the product containing formaldehyde in the building materials, the current market traffic is relatively large for the water putty, putty powder which is natural mineral powder And water-based glue synthesis, because the product life long-term pollution-free, so that is impossible to contain formaldehyde, but engineering putty is usually on-site modulation, and in order to increase the adhesion of putty powder inside the addition of a large number of construction glue (Containing formaldehyde).

- Q:Home improvement waterproofing problem

- 5, the kitchen is designed to be waterproof. In principle, there should be water and water treatment should be done to avoid the water pipe out of the problem, affecting the destruction of downstairs decorating

- Q:How does the waterproofing membrane work?

- 4, rolling the membrane: the first turn up the end of 1m long, with a long torch melting the bottom of the hot melt adhesive, the rapid paste fixed on the grassroots, and then re-harvest the rest of the volume. The gunmen stood on the paved webs, aligned with the corners of the rolls and the surface of the base layer with the flame of the long gun, and slowly rolled the edges by melting the hot melt. The web is pasted on the base;

- Q:Developers have done waterproof, decoration house also have to do it

- so, in your house When the decoration, or should do a waterproof treatment.

- Q:Finished house bathroom waterproof household acceptance should be how to accept?

- 5: the use of construction stubs should be along the direction of the flow of water, lap width of not less than 100mm, the use of two or more fiberglass cloth up and down when the overlap should be staggered width of one-half.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Underlay Membrane Water resistant and Vapor breathable

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches