Under 325 Mesh Calcined Alumina Powder AL2O3

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Under 325 Mesh Calcined Alumina Powder AL2O3

The main material of our refractory castable high alumina powder is Al2O3—SiC—C, there’s 2 types including baking casting material and free baking material, the width of iron runner is required above 2.4 meter, the depth is above 1.7 meter,it has a good performance in site operation, with easy repair, tapping iron is allowed after pouring finished. Although the invest is more higher for once time, but it will be with a longer service life and a few mending work. Refractory castable is the production and the most widely used a monolithic refractories.

Application:

It can be used to formulate unshape refractory material; expansive cement, self-stressing cement, addition material of chemical construction material and projects with special requirements.

aluminum oxide property:

It has higher hardness and slight lower toughness comparing with brown fused alumina. It is also characterized by its high purity, ability of self-sharpening, better cutting, less heat emit, higher efficiency, acid and alkali resistance, good thermal stability. As the abrasive materials, it is suitable for grinding high-speed, high carbon steel, as loose grains, it widely used for bonded and coated abrasives , polishing, precision casting and so on .

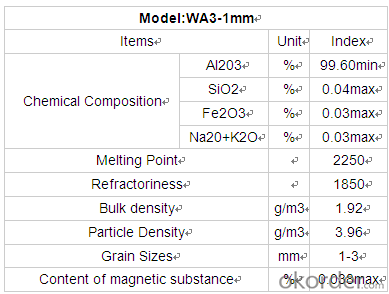

white fused alumina grits&powder chemical composition

aluminum oxide property:

Soluble in water white solid. Odourless. Tasteless. Qualitative very hard. Easy absorption of moisture and not ChaoXie. Both sexes oxide, soluble in inorganic acid and alkaline solution, almost insoluble in water and the polar organic solvents. The relative density (d204) 4.0. Melting point about 2000 °C.

The physical and chemical analysis:

Main standard:

Alumina(industry grade) made by slkali-lime sintered,It is white powdered crystal with low assay of Ti, Mn, Zn, Cu, V, Zr, Cr, Li, Pb, B, P, etc.It is used in the production of fused salt eletrorefining aluminium, corundum eramics, refractories and other alumina chemical products.

Product Pictures:

If you’ve any enquiry please don’t hesitate to contact us!

- Q:Which refractory is suitable for the tunnel kiln?

- The refractories produced by the following ten manufacturers are relatively good. They are all being the top ten brands! 1. king coconut (Chinese well-known trademarks, famous brand, the nation's largest manufacturer of wood panels, large building materials chain enterprises, Hangzhou king coconut Holding Group Co., Ltd.) 2. Fuxiang (founded in 1998, the leading professional sheet production outstanding enterprises, Fuxiang Industrial Co., Ltd.) 3. Bunny (China famous brand, China Top brand, plywood industry iconic brand, large listed companies, high-tech enterprises, Edward Bunny decoration materials Co., Ltd. 4. new Millennium boat ( Chinese well-known trademarks, famous trademarks in Zhejiang, Zhejiang famous brand, well-known trademarks in Hangzhou, Zhejiang Province key forestry enterprises, the Millennium boat Group Hangzhou Huahai Wood Industry Co., Ltd.) 5. Jin Luli (China famous brand, Chinese brand-name products, Shandong Province, to wood-based panels and steel-based enterprises, hundred private enterprises in Shandong Province, Luli Group Co., Ltd.) 6. Albert (professional fire protection board development / production and marketing of the modern manufacturer, the introduction of advanced production technology industry HPL) 7. desert oasis (China famous brand lumber, China's top ten brands plate, sheet famous Chinese brand, oasis Wood) 8. Peng Che-hung (professional fire protection board development / production and marketing of the modern manufacturer, the introduction of advanced production technology industry HPL ) 9. Worldwide (professional magnesium fire plate glass production and sales of integrated large-scale well-known enterprises, famous brands Firewood industry) 10. Mogan (national key high-tech enterprises, China's largest and most influential environment-friendly decorative materials production one of the enterprises, Zhejiang Hua Yunfeng new material Co., Ltd.)

- Q:I wanna ask about the thermal insulation material fire resistant level?

- The inorganic glass wool, rock wool and foam glass. Organic: The best is the phenolic foam, phenolic foam composite cement layer is level A.

- Q:How long is the fire endurance of the rock wool board?

- Hello. The limit is up to 2 hours. Of course such a thing is not desirable.

- Q:Fefractory of aluminium oxide.

- It can be refined into castable refractory and refractory bricks, according to temperature rating. There are shaped refractory material and shapeless refractory material, and ceramic fiber. So it must be specific. There is a large range of refractory, which basically contains the aluminium oxide.

- Q:Why does refractory need to add coarse firstly and then add fine aggregate?

- Oh, adding coarse aggregate first is to select good material to make aggregate, and the rest cna be made into fine aggregate. Because if it contains impurities, once being sintered, the appearance will be affected, but fine aggregate does not have this impact.

- Q:What's the refractoriness and how to measure the refractoriness?

- Bottom each side length is 8 mm and upper side length is 2 mm. Under a certain temperature-rising speed, when heating, refractory's resistance to high temperature from melting is called refractoriness. The properties of cross section into an equilateral triangle and height is 30 mm. When it bends down until the vertex and chassis contact temperature is the refractoriness of sample. It bends due to the influence of its weight. Make the will-measured material into standard pyrometric cone.

- Q:What do RH and DH stand for in refractories?

- DH :An agreement that allows strangers to build shared keys, originally invented by Diffie and Hellman.

- Q:What are the new refractories? What are the features? How about their application and development?

- In metallurgy, in what position should it be used, in order to make the best. Answers are as following. In iron, steelmaking or converter. When questioning, pay attention to the ways. Answers: Try to use synthetic refractory materials.

- Q:whether the aluminum silicate thermal insulation material is fireproof or not?

- Yes, it is fireproof. Refractory thermal insulation material mainly refers to the inorganic thermal insulation materials and composite thermal insulation materials. According to the shape it can be divided into: Fibrous finishing, mineral?cotton, rock wool, glass wool, aluminum?silicate?wool, ceramic fiber,ect.. it takes the flint clay clinker as raw material, produced by the fusion of resistance or electric arc furnace and the injection of fiber forming. characteristic: Low thermal conductivity, excellent thermal and chemical stability, without binder and corrosive material.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Under 325 Mesh Calcined Alumina Powder AL2O3

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords