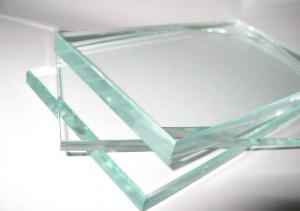

Ultra Clear Float Glass

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 100m2 m²

- Supply Capability:

- 10000m2 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Ultra Clear Float Glass is a kind of low iron and transparent glass with high light transmittance(>91%), also called low iron glass. It is a high-quality, multifunctional and newly high-end glass. Being crystal clear and elegant, it is crowned as "crystal prince" of the glass family.

Features of Ultra Clear Float Glass:

1. High clarity: 6% higher visible light transmittace than ordinary clear glass;

2. Nobility and elegance:with the unique lavender edges , it has the feeling of the the sapphire against the sunshine.

3. Safety: No detonating impurities/metallic and no spontaneous detonation.

4. Low UV transmittance and Environmentally friendly products: can effectively prevent UV radiation and protect interior items from fading and aging.

5. CE/SGS/REACH Certificates.

Specifications of Ultra Clear Float Glass:

Thickness: 2- 25mm

Size:

920*1016mm

3660*18000mm

Customized Sizes

Applications of Ultra Clear Float Glass:

Ultra Clear Glass has been widely used in various fields:

1. Interior and Exterior Decorations of Advanced Buildings: like curtain walls, glass doors of the lobby, transparent roof, glass ribs, glass suspended ceilings, partitions, walls, guard rails, stairs, etc.

2. Exhibition Hall and Showcase: in museum, exhibition hall, jewelry shop, clothing store, etc.

3. Home Appliances: as the screen protector of plasma TV, high-end visual refrigerator door, high-grade microwave oven panel, refrigerator cover, range hood cover, etc.

4. High-end Arts and Crafts, Lamps, etc.

5. Furniture and Bathroom Products.

- Q:What is glass fiber reinforced nylon?

- GFR-nylon adds a certain amount of nylon resin in glass fiber reinforced plastic (FR-PA) and can be divided into long glass fiber reinforced nylon coating prepared (fiber and plastic particles equal, generally about 10mm) and the short cut fiber after mixing, or continuous fiber guide short glass fiber into double screw extruder continuous shear mixing of reinforced nylon (glass fiber length of about 0.0.7mm. 2.) belongs to the nylon polyamide amine in its main chain. Amino is polar, due to the effects of hydrogen bonding and attract each other. So the nylon easy to crystallize, can be made into high strength fibers. Polyamide as translucent cuticle toughness or white crystalline resin, often made of cylindrical pellets for polyamide plastic with molecular weight ranging from 15 thousand to 20 thousand.

- Q:There are several appearances of the quality defects of ordinary flat glass

- The wave bar, also called the water line, is the most vulnerable and the most serious defect in the appearance defects of glass. It can cause optical distortion of glass and cause visual fatigue or visual illusion of the observer. There are many reasons for the wave reinforcement, mainly due to the backward production process and chemical composition and excessive impurity content.

- Q:Tempered and reinforced glass

- Tempered glass is a safety glass. It is very small and won't cause serious damage when broken. Toughened glass does not belong to safety glass. Large pieces of debris can cause serious damage.

- Q:How is glass made? What is its raw material?

- Glass is formed by the melting of sand with other chemicals. Glass raw materials for natural ore, the ore will be crushed first, processed into powder, according to the type of glass, according to the formula made of ingredients, into the glass furnace for melting, forming glass liquid. The glass passes through the feed tank and flows out of the feed port to form the stock. The temperature of the stock is 1150~1170 degrees centigrade and the alkali free glass is 1200~1220 degrees centigrade. The material shares every minute near '200 times cut into ball billet. The billet passes through the chute, the ball distributor and the ball plate, and then rolls into different funnels respectively, then falls into a groove formed by three rollers with the same rotating direction. When the ball is rotated on the roller and its surface tension, the ball glass is formed gradually. Its diameter is determined by the thickness, velocity, and shear velocity of the glass stream.

- Q:What are the raw materials for producing edible glass bottles (such as pickles bottles, fermented beancurd bottles, etc.), and glass is the kind of glass material?

- To the Chinese packaging bottle net glass bottle information, take a look at it, are glass bottle production technology and so on related articles, the only domestic bottle site.

- Q:Does anyone know iPhone's toughened glass production process? Thank you

- Then the glass (CNC) carved machine milling, drilling, trenching and processing; (quality check)4. followed by ultrasonic cleaning machine cold processing of semi-finished glass cleaning;5., the next step is to carry out the chemical strengthening process and enter the chemical strengthening furnace;

- Q:What is the raw material of glass?.

- 1. the main raw material of glass(1): the main component of silica sand or borax borax glass is introduced into silica or silica or boron oxide, which alone can melt into a glass body in the combustion, determines the main properties of glass, appropriately called silicate glass or borosilicate glass.(2): the main ingredients of soda soda or salt and mirabilite into glass is sodium, they can with silica sand and other acidic oxides formed in the fusible salt calcination, the fluxing action, the glass is easy to mold. But if the content is too much, the thermal expansion rate of glass will increase, and the tensile strength will decrease.(3) limestone, dolomite, feldspar, etc.: the main component of limestone introduced into glass is calcium oxide, which enhances the chemical stability and mechanical strength of glass. But the content is too much, which makes the glass break and reduce the heat resistance.As a raw material for introduction of Magnesium Oxide, dolomite can improve the transparency of glass, reduce thermal expansion and improve water resistance.Feldspar, as a raw material for introduction of alumina, can control the melting temperature and increase durability. In addition, potassium feldspar can also provide components, improve the thermal properties of glass.(4) broken glass: Generally speaking, not all new materials are used in the manufacture of glass, but the broken glass of 15%--30%.

- Q:The main raw material for the impact of float glass cost?

- Fuel prices: heavy oil, natural gas or coal, etc., because of the large number of long-term consumption, so it is also an important factor affecting product costs.

- Q:How to distinguish between good and bad glass fiber reinforced plastic?

- Glass steel will be exposed his true strength in the actual use of the process, the quality of glass steel after a few years of use color slightly dim, the whole board intact, no obvious damage, glass steel it would withstand the test of practice, after a few years of use will appear corrosion fracture pores and other obvious damage the board is not so smooth, the color degradation is serious, the overall aging, general glass steel is to be used for twenty years, but two years later will appear glass steel inferior overall aging phenomenon, thus causing great losses to customers.

- Q:The use of quartz sand

- Quartz sand is quartz quartz stone crushing processing, quartz stone is a kind of non metallic minerals, is a hard, wear-resistant, stable chemical properties of silicate minerals, its main mineral composition is SiO2, quartz sand, the color is white or colorless and translucent, Mohs hardness of 7, quartz sand is [1] an important industrial mineral raw material, non hazardous chemicals, widely used in glass, casting, ceramics and refractories, smelting, metallurgy, metallurgy, construction, chemical agent, rubber, plastics, abrasives, and other media industry

1. Manufacturer Overview |

|

|---|---|

| Location | Shandong, China |

| Year Established | 1992 |

| Annual Output Value | Below US$1 Million |

| Main Markets | North America; South America; Africa; Mid East; Eastern Asia; Western Europe |

| Company Certifications | ISO 9001:2008; |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Tianjin; Qingdao |

| Export Percentage | 1% - 10% |

| No.of Employees in Trade Department | |

| Language Spoken: | English; Chinese |

| b)Factory Information | |

| Factory Size: | 10,000-30,000 square meters |

| No. of Production Lines | 6 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average |

Send your message to us

Ultra Clear Float Glass

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 100m2 m²

- Supply Capability:

- 10000m2 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords