U profile Sheet Pile WRU

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of U profile Sheet Pile WRU:

Type | Width | Height | Thickness | Sectional area | Weight per pile | Weight per wall | Moment of Inertia | Modulus of section |

| mm | mm | mm | Cm2/m | Kg/m | Kg/ m2 | Cm4/m | Cm3/m |

WRU7-750 | 750 | 320 | 5 | 71.8 | 42.3 | 56.4 | 11089 | 693 |

WRU7-900 | 900 | 320 | 5 | 68.2 | 48.2 | 53.5 | 11308 | 706 |

WRU7-850 | 850 | 320 | 5 | 69.4 | 46.3 | 54.5 | 11244 | 703 |

WRU8-750 | 750 | 320 | 6 | 86.1 | 50.7 | 67.6 | 13191 | 824 |

WRU8-850 | 850 | 320 | 6 | 83 | 55.4 | 65.2 | 13379 | 836 |

WRU8-900 | 900 | 320 | 6 | 81.8 | 57.8 | 64.2 | 13458 | 841 |

WRU9-750 | 750 | 320 | 7 | 100 | 58.9 | 78.5 | 15256 | 953 |

WRU9-850 | 850 | 320 | 7 | 96.5 | 64.4 | 75.8 | 15478 | 967 |

WRU9-600 | 600 | 320 | 7 | 108.3 | 50.7 | 85 | 14783 | 924 |

WRU9-900 | 900 | 320 | 7 | 95 | 67.1 | 74.6 | 15571 | 973 |

WRU10-700 | 700 | 310 | 9 | 129.6 | 71.2 | 101.7 | 16270 | 1049 |

WRU10-1050 | 1050 | 310 | 9 | 116.2 | 95.8 | 91.2 | 17644 | 1138 |

WRU10-450 | 450 | 360 | 8 | 147.7 | 52.2 | 116 | 18267 | 1015 |

WRU11-575 | 575 | 360 | 8 | 133.1 | 60.1 | 104.5 | 19684 | 1094 |

WRU11-600 | 600 | 360 | 8 | 131 | 61.7 | 102.8 | 19897 | 1105 |

WRU 900×360×8 | 114.4 | 80.9 | 89.8 | 21526 | 1195 | |||

WRU11-450 | 450 | 360 | 9 | 167 | 59 | 131.1 | 20383 | 1132 |

WRU12-575 | 575 | 360 | 9 | 149.5 | 67.5 | 117.5 | 21979 | 1221 |

WRU12-600 | 600 | 360 | 9 | 147 | 69.2 | 115.4 | 22219 | 1234 |

WRU 900×360×9 | 128.5 | 90.8 | 100.9 | 24054 | 1336 | |||

WRU12-450 | 450 | 360 | 10 | 181.8 | 64.2 | 142.7 | 22443 | 1247 |

WRU13-575 | 575 | 360 | 10 | 163.8 | 73.9 | 128.6 | 24223 | 1346 |

WRU13-600 | 600 | 360 | 10 | 161.3 | 76 | 126.6 | 24491 | 1361 |

WRU 900×360×10 | 141.8 | 100.2 | 111.3 | 26538 | 1474 | |||

WRU16-650 | 650 | 480 | 8 | 138.3 | 70.6 | 108.6 | 39872 | 1661 |

WRU16-750 | 750 | 480 | 8 | 130.6 | 76.9 | 102.5 | 40496 | 1687 |

WRU18- 600 | 600 | 350 | 12 | 219 | 103.1 | 171.9 | 32797 | 1874 |

WRU18- 950 | 950 | 350 | 12 | 182.5 | 136.1 | 143.3 | 33346 | 1906 |

WRU 18-650 | 650 | 480 | 9 | 154.7 | 78.9 | 121.4 | 44521 | 1855 |

WRU18-750 | 750 | 480 | 9 | 146.1 | 86 | 114.7 | 45241 | 1885 |

WRU20- 600 | 600 | 350 | 13 | 238.5 | 112.3 | 187.2 | 35224 | 2013 |

WRU20 | 650 | 540 | 8 | 153.7 | 78.1 | 120.2 | 56002 | 2074 |

WRU23-650 | 650 | 540 | 9 | 170 | 86.8 | 133.5 | 62588 | 2318 |

WRU23-750 | 750 | 540 | 10 | 175.9 | 103.5 | 138.1 | 61340 | 2272 |

WRU26 | 650 | 540 | 10 | 187.5 | 95.7 | 147.2 | 69093 | 2559 |

WRU30-700 | 700 | 560 | 11 | 215.8 | 118.6 | 169.4 | 83813 | 2993 |

WRU30-750 | 750 | 560 | 11 | 208.7 | 122.9 | 163.8 | 83752 | 2991 |

WRU32-700 | 700 | 560 | 12 | 234.5 | 128.9 | 184.1 | 90880 | 3246 |

WRU32-750 | 750 | 560 | 12 | 227 | 133.6 | 178.2 | 90828 | 3244 |

WRU35-700 | 700 | 562 | 13 | 245.3 | 144.3 | 192.5 | 98607 | 3509 |

WRU36-700 | 700 | 558 | 14 | 284.3 | 156.2 | 223.2 | 102145 | 3661 |

WRU39-700 | 700 | 560 | 15 | 303.8 | 166.9 | 238.5 | 109655 | 3916 |

WRU41-700 | 700 | 562 | 16 | 323.1 | 177.6 | 253.7 | 117194 | 4170 |

WRU 32 | 750 | 598 | 11 | 215.9 | 127.1 | 169.5 | 97362 | 3265 |

WRU 35 | 750 | 600 | 12 | 234.9 | 138.3 | 184.4 | 106416 | 3547 |

WRU 38 | 750 | 602 | 13 | 253.7 | 149.4 | 199.2 | 115505 | 3837 |

WRU 40 | 750 | 598 | 14 | 282.2 | 166.1 | 221.5 | 119918 | 4011 |

WRU 43 | 750 | 600 | 15 | 301.5 | 177.5 | 236.7 | 128724 | 4291 |

WRU 45 | 750 | 602 | 16 | 320.8 | 188.9 | 251.8 | 137561 | 4570 |

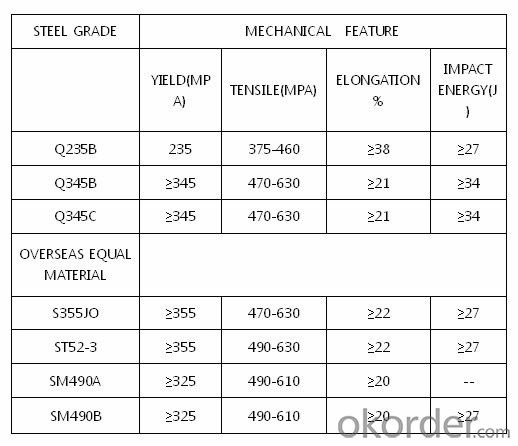

Steel Grade for Sheet Pile

Usage and Applications of U profile Sheet Pile WRU:

1. Used for the permanent constructional structure such as embankment, harbors, docks, retaining walls, anti-earthquake reinforcement project, flood gates, etc

2. used for the provisional structure to seal the mountain, provisionally to retain the wall, to cut off the river, to cofferdam, to lay the pipeline and to ward off the earth, the water or the sand

3. Used for the flood-fighting and emergency rescues to prevent the flood, collapse, sink or sediment flow, etc.

Advantage of U profile Sheet Pile WRU:

U sheet pile is a service-proven type familiar to both designers and constructors, which is extensively used for permanent structures, temporary earth-retaining works and temporary cofferdams, etc

In addition to its rigid structure, its moment of inertia per pile is relatively large, thus allowing repetitive use

Available in a range of sections, with section modulus values ranging from 456 to 4042 cm3/m

- Q:How do steel products contribute to sustainable development?

- Steel products contribute to sustainable development in several ways. Firstly, steel is a highly recyclable material, which reduces the need for mining and extraction of new raw materials. This helps conserve natural resources and reduces the environmental impact of steel production. Additionally, steel has excellent durability and strength, leading to long product lifecycles and reducing the frequency of replacements. This not only saves resources but also reduces waste generation. Furthermore, steel is widely used in construction and infrastructure projects, contributing to the development of sustainable and resilient cities. Its ability to withstand extreme weather conditions and seismic events makes it an ideal choice for building structures that are durable, safe, and energy-efficient. Overall, steel products play a crucial role in promoting sustainable development by conserving resources, reducing waste, and creating resilient infrastructure.

- Q:How is steel used in the production of marine vessels?

- Steel is commonly used in the production of marine vessels due to its high strength, durability, and resistance to corrosion. It is used to construct the hull, decks, and other structural components, providing the necessary strength to withstand the harsh conditions of the marine environment. Steel also enables the vessels to carry heavy cargo and withstand the forces exerted by waves and currents. Additionally, steel can be easily welded and shaped, allowing for efficient construction and customization of marine vessels.

- Q:What are the different types of steel products used in the manufacturing of toys and games?

- The different types of steel products used in the manufacturing of toys and games can include steel wires, steel rods, steel sheets, and steel tubes. These materials are commonly used to create structural components, hinges, axles, and other mechanical parts in various toys and games.

- Q:What are the different types of steel fasteners and their uses in the aerospace industry?

- There are several different types of steel fasteners commonly used in the aerospace industry, including bolts, screws, nuts, and rivets. These fasteners are essential for joining various components and structures in aircraft manufacturing and maintenance. Bolts are typically used to secure heavy loads and provide strong connections, while screws are used for lighter applications. Nuts are used in conjunction with bolts to create a threaded connection. Rivets, on the other hand, are used to permanently join materials together by deforming the fastener upon installation. Each type of steel fastener has its specific uses and strengths, contributing to the overall safety and reliability of aerospace structures.

- Q:What are the different types of steel tanks and their applications in the chemical industry?

- There are various types of steel tanks used in the chemical industry, each with specific applications. Some common types include carbon steel tanks, stainless steel tanks, and alloy steel tanks. Carbon steel tanks are versatile and widely used for storing liquids, gases, and chemicals. Stainless steel tanks are corrosion-resistant and ideal for storing corrosive chemicals or materials. Alloy steel tanks are used for specialized applications that require high strength and resistance to extreme temperatures. These tanks are crucial for storing and transporting various chemicals and substances safely in the chemical industry.

- Q:What are the common types of steel products used in the travel and tourism industry?

- Some common types of steel products used in the travel and tourism industry include luggage racks, luggage carts, airport trolleys, crowd control barriers, and signage structures.

- Q:What are the applications of alloy steel in the energy sector?

- Alloy steel finds numerous applications in the energy sector due to its exceptional strength, corrosion resistance, and heat resistance properties. It is commonly used in the construction of power plants, oil and gas pipelines, and offshore platforms. Alloy steel is also utilized in the manufacturing of turbine blades, reactor vessels, and other critical components in nuclear power plants. Its high temperature and pressure resistance make it suitable for steam boilers and pressure vessels. Additionally, alloy steel is used in the production of high-strength bolts and fasteners, ensuring the structural integrity and safety of energy infrastructure.

- Q:What are the different methods of joining steel components together?

- There are several methods of joining steel components together, including welding, bolting, riveting, and adhesive bonding.

- Q:How are steel products used in the telecommunications industry?

- Steel products are used in the telecommunications industry for various purposes, such as constructing telecommunication towers, satellite dishes, and cable trays. These steel structures provide the necessary support and stability for antennas, satellite receivers, and other communication equipment. Steel is also used in the manufacturing of cabinets and enclosures, which protect sensitive communication devices from environmental factors. Additionally, steel is used in the production of underground cables and conduits, ensuring the safe and efficient transmission of telecommunication signals.

- Q:What are the different types of steel tanks and vessels available?

- There are several different types of steel tanks and vessels available, including carbon steel tanks, stainless steel tanks, pressure vessels, storage tanks, mixing tanks, and fermentation tanks. Each type serves a specific purpose and is designed to meet various industry requirements, such as chemical storage, food processing, pharmaceutical manufacturing, or water treatment.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

U profile Sheet Pile WRU

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords