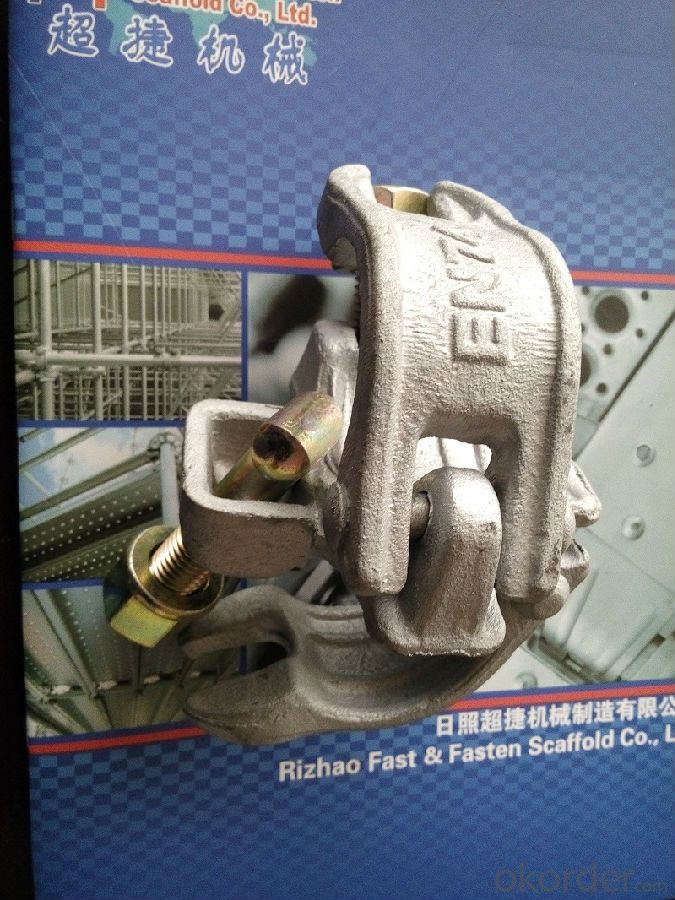

Types of scaffolding drop forged Swivel coupler

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 10000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

British Type Swivel Coupler

Size: 48.3mm, Weight: 1.20kg

Surface: electro galvanization, hot dip galvanization,

Material: Q235

Standard: EN74 OSHA

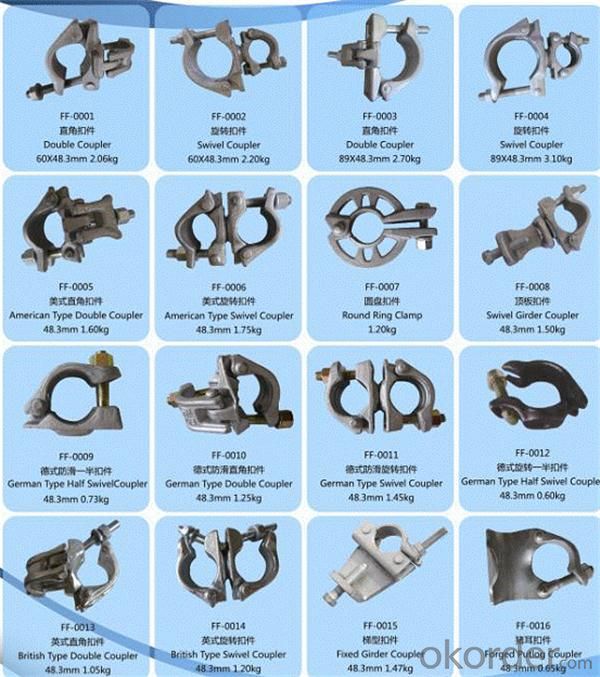

German Type Swivel Coupler

Size: 48.3 X 48.3mm

Weight: 1.45kg

Surface: electro galvanization, hot dip galvanization,

Material: Q235

Standard: EN74 OSHA

American Type Swivel Coupler

Size: 48.3X48.3 mm

Weight: 1.75kg

Surface: electro galvanization, hot dip galvanization,

Material: Q235

Standard: EN74 OSHA

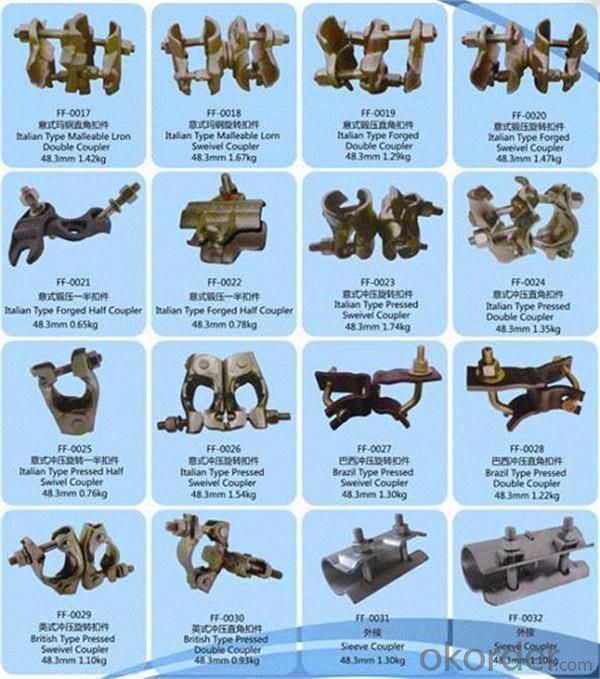

British Type Swivel Coupler

Size: 48.3mm*76mm , Weight: 1.85kg

Surface: electro galvanization, hot dip galvanization,

Material: Q235

Standard: EN74 OSHA

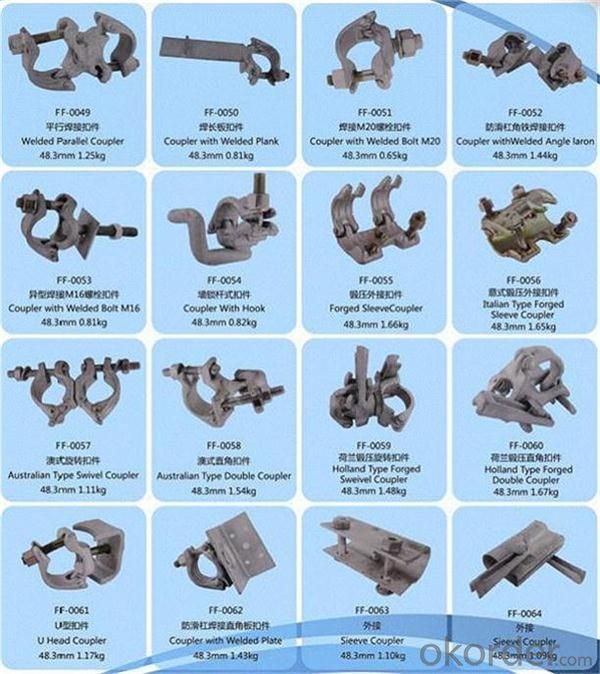

We can supply many types of pressed and forged scaffolding couplers, such as swivel coupler, double coupler, sleeve coupler, putlog coupler, German type, British type, American type, Japanese type and so on.

Rizhao Fast and Fasten Scaffold Co., Ltd. is a professional manufacturer and supplier of scaffolding systems, scaffolding couplers, and other related products. With good quality and competitive price, our products are very popular in European, Australia, North America, Mid-east, and South East Asia and some African countries.

- Q:21M high full scaffold erection scheme

- 2 should be based on the results of the inspection to improve the construction organization design of the demolition of the order and measures, approved by the competent authorities before the implementation;3 removal of debris and ground barriers on the scaffold.4.2 removal of scaffolding, should meet the following requirements:

- Q:Room 29 meters outside the wall of the two rows of steel pipe scaffolding installation, demolition, joint protection measures in Wuhan, the price per square is how much money? A friend to help refer to Kazakhstan

- When the double row scaffolding longitudinal distance 1.5m, horizontal distance 1.2m, step 1.8m, as per 100 square meters of double row scaffolding rod parts

- Q:Who has external scaffolding construction program

- Construction preparation1.1 parts1.1.1 pipe1 scaffolding steel pipe with Phi 48mm, wall thickness of 3.5mm; horizontal horizontal bar maximum length of 2200mm, the maximum length of other rods 6500mm, and the maximum quality of each steel pipe should not be greater than 25kg.2 the size and surface quality of steel pipe shall meet the following requirements:1 new steel pipe should have quality certificate, quality inspection report; steel surface should be straight and smooth, should not have cracks, scarring, stratification, dislocation, hard bend, burr, indentation and deep way;

- Q:What is the difference between Scaffolding and Zone of Proximal Development?

- Taken from okorder: Vygotsky believed that when a student is at the zone of proximal development for a particular task, providing the appropriate assistance (scaffolding) will give the student enough of a boost to achieve the task. Once the student, with the benefit of scaffolding, masters the task, the scaffolding can then be removed and the student will then be able to complete the task again on his own.

- Q:i have some ?'s on the scarlett letterWhat effect has the 7=year interval had on Dimmesdale ?

- you can see how weak morally dimmesdale is, because he keeps his hand over his heart all the time, and is constantly beating himself up over his crime. he whips himself in the closet, and brands himself with a scarlett a to match hesters. hester... when she first walks out on the scaffold she can be seen as defiant, as if she isn't ashamed of the embellished letter a she wears. the cottage she lives in is on the edge of the town, bordering the forest. towards the end of the 7 years, her actions can be seen as repent maybe for her crime: she is a self ordained sister of mercy, helps the poor and homeless, sews... and the a turns from adultery to able

- Q:I have some scaffolding that I would like to use to build a temporary slide to my swimming pool. The slide I would like to be made out of the side parts which are the ones like rectangles with bars going across them and I have a variety of poles. I would then like to put a slippery tarpaulin on to the frame.But how would I hold the tarpaulin up, because the metal poles will be too short? So that if someone slid down it they would not just burst through the tarpaulin and hit the floor after hitting around five metal poles!

- Why would you even consider something like that? Obviously you kids and your family use this pool, why put them at risk making a temporary slide with scaffolding. Not a good idea.

- Q:Hi(: My names Tasha, and I love piercings. (I have 8) And I want to get an industrial piercing(Some call it a scaffold). But my ear doesn't have a bend like most people do.I got my first four piercings done by a professional. But felt I was much more comfortable having my brother(22) do it. Since he's someone I know, and hes done piercings and stuff before.

- This is why you need a pro. I can see where you should probably put a helix-to-helix industrial in that ear, but if yall can't see it, then I don't think you should be trying this, as neither of you have the experience a professional piercer does.

- Q:For indoor use of mobile scaffolding safety construction plan! Four support points with four pulleys with brake!The construction scheme of scaffolding safety belt for indoor high Jiqiu braking pulley, for about 12 meters of buildings, indoor emergency please heroes!

- Double pole scaffolding and scaffold for decoration of the vertical distance rod step distance should be less than or equal to 2.0m. peaceFrom the operation layer (floor) scaffold surface height is over 2.0m, the width of working layer deck should not be less than: scaffold for 750mm in scaffolding for the clearance of 500mm. edge of the plank and wall should be more than 300 mm, and blocking foot clearance should be more than 100mm. when the side board is not close to the pole, should with reliable fixation.

- Q:I couldn't believe it, but yes it happened...

- With God all things are possible.

- Q:also apprx. what chapters is it in?

- The Democrats took decrease back a majority particularly through attacking Republicans on the unpopularity of the conflict and Bush's adverse approval rankings. there have been additionally various ethics scandals concerning republicans that twelve months that led to various of them resigning their seats and a regular loss of self belief that strengthened Democrat momentum. Tom postpone resigned after being charged with marketing campaign finance violations. He substitute into never convicted. Mark Foley sexually under pressure an underage male congressional website. The Abramoff indictment solid suspicion on all and sundry in Washington, extraordinarily those in ability. Scooter Libby substitute into Indicted. It substitute into basically a nasty twelve months to be a republican. a brilliant number of the scandals disappeared after the elections and became out to be not something. some indictments caught, and extremely, in basic terms as many democrats have been grimy as republicans. yet comparable to a corrupt regime helped positioned the democrats on top of issues. Then all their can provide to question Bush and end the conflict dwindled into not something as they took over the political equipment and grew to alter into as corrupt as a results of fact those they replaced.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Types of scaffolding drop forged Swivel coupler

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 10000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords