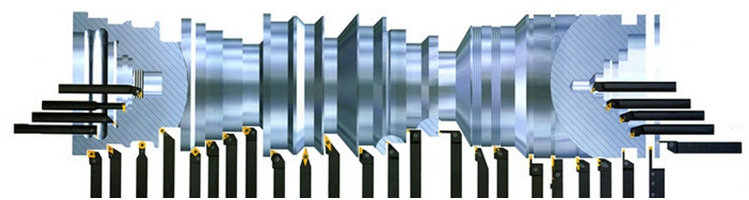

Turning Tools Metal Lathe Cutting Tools Diamond Cutting Tool

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 pc

- Supply Capability:

- 90000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of cutting tool:

Including external turning tool holders, boring bars, threading holders, grooving holders, cartridge and micro turning tools.

As the first product, our turning cutting tools has the following impassable advantages:

· our turning cutting tools cover a wide application range with a full line-up of ISO cutting tools that produce high quality and high precision cutting tools and parts for all manufacturers’ requirements.

· Main cutting tool’s type include external turning tool holders, boring bars, threading holders, grooving holders, cartridge and micro turning tools.

· All the spare cutting tools are made by ourselves, stable and controllable quality can reduce the wear of the insert and adjustment time.

Application

· Mainly use for turning machine, boring, grooving and threading in NC Lathe.

- Q:The Angle of the turning tool

- Edge clearance Angle The Angle of the edge of the knife is the Angle of edge clearance. The edge clearance Angle creates a space between the work surface and the side of the knife to concentrate the cutting effect on cutting efficiency. The Angle of high speed steel is about 10 to 12 degrees.

- Q:What kind of car knife makes the surface of an artifact very good?

- It's not a car knife problem. Any R angles need to be combined with the speed. The speed of the cutting. The speed of the feed. The cutting agent. And the material of the tool

- Q:How is the rough lathe of CNC lathe and the fine lathe tool divided?

- The following terms should be familiar if you are familiar with every Angle of the car knife: Front Angle: the Angle of the cart is smaller and the car is larger. Rear Angle: the rougher Angle is smaller (6-8 degrees) and the fine car is larger (10-12 degrees). Tip Angle: when a rough car is usually 5 degrees, it will be 10 or larger when it is large. In fine cars, the average is -4 degrees. Main Angle: according to machine tool - workpiece - tool system stiffness choice. Side Angle: according to surface roughness choice, high time Angle is smaller. Radius of the tip of the blade: generally hard alloy tool, r = 0.5-2mm, and small when rough. You can do the same with the above data sharpener

- Q:How to weld a car knife? How do you handle the welding fire

- I put the knife in the pole and put it on the bottom of the pole. Don't burn the alloy. When the blade is red, the alloy is turning red. Where the copper is hot. Don't burn your ass, you'll have more experience...

- Q:What is the best Angle for a car knife

- The distance that the tool moves at each turn of the workpiece, called the quantity of feed, is expressed in terms of f (mm/r). The thickness of the metal layer, which is cut each time, is called cutting depth, which is represented by the ap (mm). In order to ensure the quality of processing and improve the productivity, the parts process should be phased in, the parts of the medium precision are carried out in the plan of the cart. The purpose of the rougher is to cut the bulk of the machining from the blank as quickly as possible, and make the workpiece in the shape and size of the requirement. Coarse car give priority to in order to improve the productivity, increase the cutting depth in the production, to improve the productivity in the most favourable, followed by appropriate increase feed, and adopts medium or medium to low cutting speed. Using high speed steel lathe tool for rough turning cutting dosage recommendations are as follows: cutting depth ap = 0.8 ~ 1.5 mm, feeding the f/r = 0.2 ~ 0.3 mm, cutting speed v take 30 to 50 m/min (steel).

- Q:Does the grinder work with the grinder or the universal grinder?

- The cuttings of the grinding blade depend on the shape, width, depth, depth of cutting, depth of feed, and quantity of feed. Under normal circumstances, the chip breaker groove shape is outside the horoscope, namely narrow near the cutter bar (90 - degree cylindrical turning), can force the chip broken crumbs, if in eight states, can make the chip curling into spring shape, reduce the machine speed, increase the feeding, the measure such as open cooling fluid can force the chip broken crumbs, chip breaker groove depth can not be too shallow, of course. But large plastic materials to it is very difficult to chip breaker, such as stainless steel 304, like this material is unlikely to chip breaker, this case is to find a way to make it curl into spring shape.

- Q:What kind of car knife works well?

- According to the material of the workpiece to determine the use of the tool, there is no better turning tool, only the most suitable car knife.

- Q:How do you tell the difference between the outside round and the inside round tool?

- When the inner circle is in the rib, it is a fan. The sharp corners of the knife should be the same as the thread's rib Angle, usually 60 degrees. The external turning tool is not required.

- Q:Which direction does the transverse orientation of the lathe point in?

- It's going in the direction of the axis. Vertical is the radial feed.I hope my answer will help you.

- Q:What is the main Angle of a common external turning tool?

- The Angle of the Angle, the rear Angle, the rear Angle, the Angle of the main, the Angle of the Angle, the Angle of the blade, and the Angle of the wedge. The first floor says the main Angle.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Turning Tools Metal Lathe Cutting Tools Diamond Cutting Tool

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 pc

- Supply Capability:

- 90000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords