Tunnel Steel Formwork in Automatic Hydraulic

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

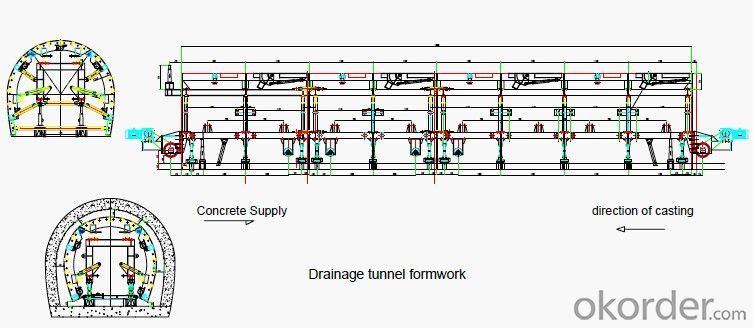

TUNNEL FORMWORK

The automatic hydraulic tunnel formwork is the equipment to make

the concrete lining for the tunnel in one time.The empty gantry allows the

transport vehicles to pass. The motor gearbox is adopted to drive

the whole equipment, the formwork is fully hydraulic, with hydraulic

cylinder to prop & strip, and lock mechanically

◆ Good concreting quality

◆ High-speed of installation and removal of the form

◆ Easy operation and safety

- Q:How to put the positioning point is based on what is mainly based on my novice, do not

- The trolley positioning, the first to the two lining trolley running mileage, and positioning, positioning process will have been completed two off the top two tight lining lining, free end positioning first center point positioning control of elevation and with a plumb line (top surface elevation is equal to the length of the plumb line + if the mileage of two the center point of elevation can be lining),

- Q:Main diseases and prevention of tunnel

- Tunnel shotcretePhenomenon: the concrete spray layer and the rock surface is not bonded, concrete spray layer between the bond is not good.Cause analysis: the loose rock not clear spray surface; shotcreted rock debris is not scum washing or flushing thoroughly with wind pressure, water pressure; surface by spraying water, water, water concentration of untreated concrete spraying interval; before a layer of spray surface without wind, water washing scum. The air pressure is inconsistent with the spray distance.Preventive measures: remove the loose rock, clear surface by spraying of water, slag floating debris; water, concentrated water point of the surface by spraying with gouge, guide the drainage treatment of buried pipe; sprayed concrete before spray test, to determine the wind and spray distance coordination relationship between.

- Q:Design of lining concrete is C30, what should be used in the construction of concrete arch cushion concrete?

- Now the actual project is basically C15, if the economy is less than C15.

- Q:Demolition of tunnel bearing formwork for several days

- With the temperature, the need for concrete strength of 100% to remove the template

- Q:How the arch of the tunnel concrete pouring up, how to support before pouring, using I-beam is directly support the earth?

- Small pipe or large, medium pipe shed is the advanced support for the broken rock area or into, out of the hole, of course, grouting, grouting without losing the significance of the implementation.

- Q:The tunnel has the super big pipe shed and the lead small conduit, is carries on the blasting excavation first or carries on the advance support first, has the anchor rod in the tunnel, this between the construction craft order is any

- The excavation of invert waterproof plate, blind pipe and steel bar at the bottom of the tunnel, and the pouring of invert arch

- Q:Would you please tell me the difference between the concrete and shotcrete in the tunnel?

- These two kinds of concrete construction method is actually the difference.Formwork concrete: after the formwork is good, the concrete is the concrete, such as the tunnel lining, the bridge pier and so on.

- Q:12 meters of the tunnel car, under normal circumstances, one of the two months to be able to cast a few models?

- Seven hours after the maintenance of formwork, pouring a every day is no problem, that is to say a month to about fifteen die casting.

- Q:What is the concrete construction of the tunnel invert

- As the name implies, concrete is the concrete that needs to be supportedv

- Q:I would like to know the safety awareness of the tunnel lining formwork trolley Prawns to help answer oh

- No special requirements, not special equipmentFirst of all, it must be the track, the sleeper to the sleeper rail

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Tunnel Steel Formwork in Automatic Hydraulic

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Related keywords