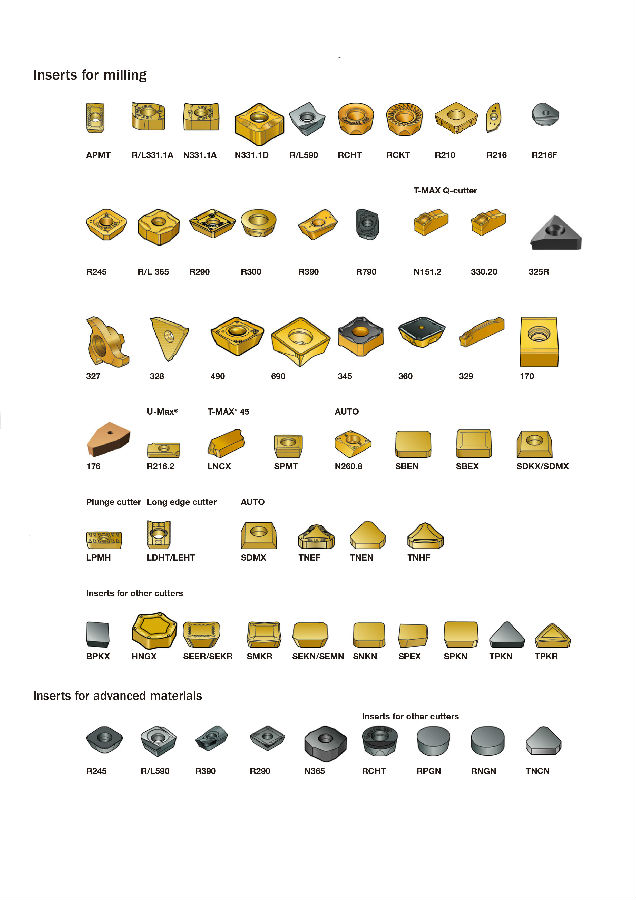

tungsten carbide inserts for cutting tool

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 pc

- Supply Capability:

- 90000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Information

- pure tungsten carbide material, recycling material is available

- Size of the inserts:OD limited crabide to 400 mm,thickness above 2mm

- Manufacturering carbide products including TC ball,bar material,wortle,strips,tips,dies,milling cutters,scraper blades,rods,inserts and so on.

- Factory price,manufacturing irregular shape according to your inserts' drawing

Packaging

1,soft foam to prevent the surface being scratched in one small carboard boxes, several small boxes in one larger hard carboard with fills to avoid a slope, besides hard carboard is easy to load and transport

2, we can also arrange packaging according to your special requirements or discuss

3,product code on cardboards instead of any company information such as logo to keep deal information secret and beneficial to customs clearance

Shipping

There are three ways to be choose, as follows:

- International Express: UPS,TNT,DHL

- Port transportation: all ports

- We delivery products according to customer’s requirements and paid by buyer after the destination confirmation

- take insurance for the goods according to contract

Our Service

- ISO , BV certificate and sound testing equipment to assure the quality

- Professional advice for the application problems, we accept return of goods with quality problems or discuss

- Survey Email of products usage will be sent timely to listen your feedback,our aim is trying to make everyone of our customers satified!

- Q:How to sharpen the blade of a lathe?

- The grinding of a lathe blade is as follows: 1, choice of grinding wheel It is advisable to use 46 # ~ 60 # grain size and medium hard alumina (corundum) grinding wheel when grinding high speed steel. It is suitable for the green carbide grinding wheel of 60 # ~ 80 # and medium to medium hard. In rough grinding, the wheel of small size is used; When grinding, the grinding wheel of a larger size is used

- Q:How does the reverse turning tool on a CNC lathe use the knife?

- Lathe itself have a mechanical origin, you generally try to cut at the time of the knife, such as car outside diameter Z to quit after a knife, how much is the diameter measurement of car parts, and then you use a knife was found in the G pictures, move the cursor to the X input X... According to the measuring machine will know that the cutter location point position, inner diameter, Z to simple, put every knife to touch a place in the Z Z0 and measurement. All of these knives have a record, which determines that the processing zero is in the artifact movement (offshift), which determines the origin of the artifact at any one. The knife should be read before the knife. There is a more convenient method, is to use clamp to knife, we know that the clamp diameter cutter to touch input diameter can, to inner diameter can take a gage block pressure on clamp head on with the hand, the same input clamp diameter is ok.

- Q:How many degrees are used in the car knife

- The car knife is the same as the tip of the outside of the car, but there is a circular fixture on the small towed board!

- Q:The lathe tool, milling cutter, planer, bit, boring tool, the cutting fluid which is used for machining, the effect is good?

- Turning, milling, planing tool, drilling, boring cutter, these are as part of the carbide, carbide processing, have a more targeted, is one of the microemulsion cutting fluid.

- Q:How to use a lathe tool

- Car knife: external turning tool, face turning tool, cutting knife, inner hole tool, threading tool. The Angle of the car knife is: the front Angle, the rear Angle, the rear Angle, the Angle of the blade, the Angle of the main and the side Angle. (1) gamma 0: the Angle between the front and the base, measured in the main section. The size of the front corner influences the sharpness and strength of the cutting edge. It can reduce the cutting force and reduce the cutting temperature, but it can reduce the strength of the blade and cause the blade to be damaged easily. Scope: - 8 ° to + 15 °. The general principle of the former corner is that the size of the anterior Angle is related to the cutting of the cutting part of the tool, the processed materials and working conditions. When the cutting parts of the cutter are brittle and low strength, the front Angle should be small. When the material strength and hardness of the workpiece are low, it can choose the larger front Angle. In the case of heavy cutting and shock working conditions, the front Angle can only take smaller values, sometimes even negative. In order to ensure the cutting edge strength of the tool, try to choose the large front Angle. When machining steel material such as carbide tool rake Angle value optional 5 °, 15 °. (2) the Angle alpha 0: the Angle between the blade and the cutting plane in the main section, measured in the main section. The effect is to reduce the friction between the blade surface and the workpiece. It also affects the strength and sharpness of the blade as well as the anterior horn. Selection principle is similar to the anterior horn, general 0 to 8?

- Q:What are the special requirements for a blind car knife?

- Simply put. The Angle of the blade is less than 90 degrees, about 80 degrees. (actually the look line, as long as live not collision hole bottom line, as to how many degrees would amount) this point is more stress, don't car too thick.

- Q:How many lathe knives are there?

- Indexable turning tool A turning tool is a machine tool with indexable blade. After using a cutting edge blunt can rapidly transfer to the adjacent new cutting edge, can continue to work, until all the cutting edges on the blade have been using blunt, blade to scrap recycling. After replacing the new blade, the tool will continue to work.

- Q:High frequency welding tool technology

- Then an old welder had resoldered it, and it was just the place.I hope my answer will help you.

- Q:How do you understand the height of the tip center

- Blade height, mainly affect the tool before cutting the actual Angle, high, before the actual Angle, sharp cutting tool, cutting tool rigidity reduced at the same time, can be used in finish machining. On the other hand, the lower the actual front Angle is smaller, the tool becomes blunt but the rigidity increases, can be applied in rough machining.

- Q:The tip of the tool tip

- The tip of the blade is also referred to as the transitional cutting edge, which is a cutting edge between the main and the side angles. Transition cutting edge effect is to enhance the intensity of blade, reduce the point of cutting thickness, make the finished surface is formed under the small cutting thickness, is conducive to improve the surface finish of workpiece, improve the point of the cooling conditions, reduce wear and tear.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

tungsten carbide inserts for cutting tool

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 pc

- Supply Capability:

- 90000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords