Tubing Coupling of Size 2-3/8 EU J55 with API 5CT Standard

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 PCS

- Supply Capability:

- 200000 PCS/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1) Structure of Tubing Coupling of Size 2-3/8 EU J55 Description

Tubing Coupling can be widely used in cold and hot water supply, heating supply, fire protection, medicinal gas, industrial petroleum pipeline system etc.

It has already replaced welding fittings in most Europe countries, Asia countries, America, Australia and some other countries.

2) Main features of Tubing Coupling of Size 2-3/8 EU J55

The quality of our products are very good, customers are all very satisfied. We have professional service team and export experience for a lot of years, our products have exported to more than 200 countries in the world. Here you can take easy choosing your needed products.

This product is 2-3/8 EU J55 tubing coupling,used to connect oil tubing pipe, which is transporting oil and gas from underground to the suiface after the drilling is completed.

3) Tubing Coupling of Size 2-3/8 EU J55 Images

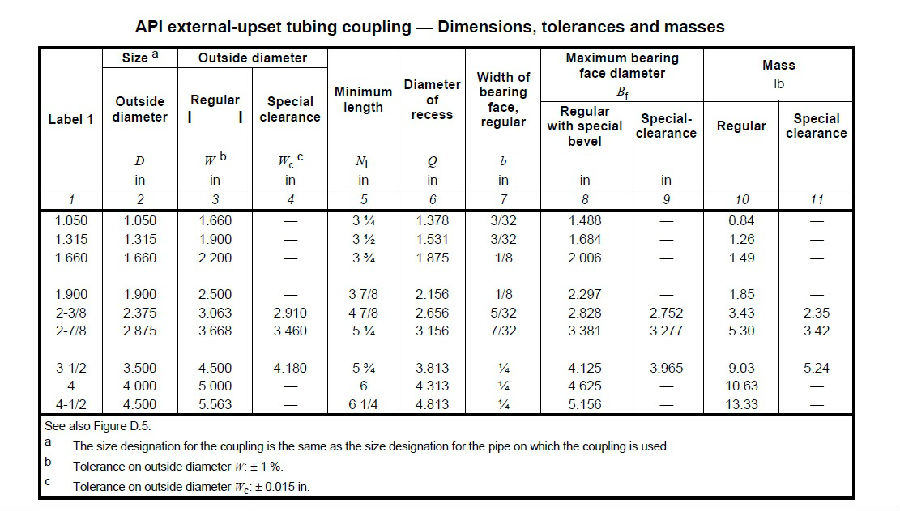

4) Tubing Coupling of Size 2-3/8 EU J55 Specification

5) FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

One of the leading manufacturers and suppliers specializing in steel pipe products in China, mainly offering four series steel pipes including welded steel pipe (ERW, SSAW, LSAW and square and rectangle pipe), seamless steel pipe, hot dipped galvanized steel pipe and steel pipe with 3 layer polythene coating. We can provide customers different specification standards e.g. ASTM A53, ASTM A106, BS1387, API 5L, API 5CT, ISO3183 and etc. Our scope of supplying covers from 1/2" to 48" for the outside diameter of welded pipes, and 1/8" to 20" for the seamless pipes.

Other than steel pipes we are also capable of supplying a wide variety of pipeline accessories, steel pipe fittings; valves etc. consists of our one-stop sales. The integrated sales & service ensures customers with various demands an easier access for purchasing management.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible.

- Q:myspace proxy?

- you should get a connector [[ just a straight pipe that is about three inches long ]] and follow through with the correct size to fit for your extension the use of the white teflon tape will help you seal those joints so you do have any leaks .

- Q:I recently got my heater repaired after it was making some unusual noises. That same day, the fire alarm went off 2 times during the day and once during early hours. The next day, the fire alarm went off twice again. My alarm company claimed they had called me each time the alarm went off, but this was not the case. They alerted the fire department the fifth time without my consent, and the fire truck arrived at my house. Luckily, I was not charged but I most definitely do not want this to happen again!It's not smoke, though there is this smell that comes from the heater. What is making the fire alarm go off? There really is no problem with the heater at this point.. is my fire alarm too sensitive? Thanks for your help!

- Without knwing how old the pump is, I would guess the bearings in the pump or pump motor are starting to wear. As they wear, they will vibrate. If there are grease fittings, add a pump of grease from a grease gun. DO NOT OVER GREASE, this is onl a temporary fix. Once the bearings start to wear, they are finished and will get worse. Sorry I have no good news.

- Q:What's the difference between pipe repair device and clamp type flexible pipe joint?

- Stainless steel pipe repair machine, plate repair machine mainly adopts 201 stainless steel manufacturing, suitable for low pressure pipeline, the general scope is 16 kg, can not solve the problem of limit, limit will not be able to solve problems of flexible axial compensation.The clamp type flexible pipe joint needs welding, but the pressure range is big, 10-220 kilograms of pressure can bear, and it has the limit function, at the same time provides the effective flexibility and the corner to the limit. The utility model is generally used on pipelines of more than 16 kilograms, and the cost is greatly lower than the flanges and the telescopic devices.Two kinds of pipe fittings can not be said which is easy to use, in the right place to use.

- Q:Why do dogs pee on anything upright? Tree, fire hydrant etc?

- Cut the pipe that is leaking about 6 either way from the leak. use a pipe cutter so you will have a nice clean cut. You will be replacing about 1 foot of pipe. Get the proper size pipe and two collars. Mark the pipe one half the distance of the collar so the collar will be centered. Install the new pipe and collars and solder them back together. When you heat the pipe to solder the new one in heat the pipe and not the collar. When the pipe and collar are hot enough it will accept the solder. If you don't know how to solder you can buy compression fittings and use a wrench. Soldering is not that hard to do.

- Q:does anybody know a great place online to buy motorcycle or moped alarms?TIA,Luke

- obviously you aren't native since you don't seem to know much about the ceremonies. why do you want to mock other people's beliefs? if these really were your beliefs you wouldn't have to ask this on YAyou would have elders to consult. i would never think to take a traditional belief and make it modern .

- Q:Which gospel choirs, which bluesmen, which jazzers - who???

- No. That will be the time for open rebellion. We will either succeed or find a quick way out of the situation.

- Q:a lightning rod of iron of diameter 0.8 cm and length 0.5m is struck by lightning and carries a current of 1 x 10^4 A. What is the potential drop?

- If they're standard pipe sizes and the join is purely functional then why not a standard compression fitting from a plumbing hardware store? If you want it to look better then you could insert one pipe inside the other and glue the overlap together- an expoxy should bond to both or silicone sealant for a more flexible bond If you have workshop tools, you could try threading the ends and bolting them together with o-rings to seal What is the fluid to be carried, how permanent a join and what environment will it operate in all need to be defined to give a better answer really!

- Q:I was wondering if police ask you if your friends smoke marijuana, and if they do ask you how serious is the question? I don't smoke but my friends do, how will this affect my chances?

- under your sink there is a U shaped pipe with a big nut around each end. loosen the two big nuts (put a pan under it first to catch the water) and the piece will come right out. You might need a pair of channel locks or big pliers to get it loose. It should not be to tight so you might be able to get it to come loose by putting a rag around it to get grip on it. After you get it out just clean it out and replace the same way it came apart. Snug the nuts back down and check for leaks. Its a fairly simple task.

- Q:What's the meaning of the pipe joint 14-M18*1.5? What's the thickness of the wall?

- (two) prohibit adding sealant and other fillers. Some people in order to obtain better sealing effect, in the card cover with sealant, the result of sealant is poured into the hydraulic system, causing hydraulic components, such as plugging holes. (three) when connecting the pipe, the pipe should have enough deformation allowance to avoid drawing the tube. (four) when connecting the pipeline, the lateral force should be avoided, and the lateral force will cause the seal to be too tight. (five) when connecting pipelines, should be a one-time good, avoid repeated disassembly, otherwise it will make poor sealing performance. Sleeve type pipe joint installation (1) of the pipe should need pickling pickling treatment according to the ninth chapter; (2) tube machine equipment cut tube with special cutting or sawing machine according to the required length, absolutely not allowed by fusing (such as flame cutting) or grinding wheel cutting; remove pipe end burr, metal cutting inside. Dust and dirt; remove the rust and dirt pipe joint; and also to ensure pipe roundness; (3) the sleeve nut, successively sheathed in the pipe sleeve front edge (small end) from the pipe mouth at least 3mm, then the pipe is inserted into the connector body bore, top to check; (4) slowly tighten the nut, while rotating the pipe until does not move, then tighten the nut 2/3 ~ 4/3 circle; (5) open the check card sets whether has cut the pipe correctly. The clamping sleeve does not allow axial movement, but slightly rotates; (6) after checking, tighten the nut again.

- Q:I am professional working as manager procurement in the manufacturing industries deals in water treatment technology and power sector companies.

- if the pips are in the same form of shape most likely those kinda things usually are interchangeable but check the fittings that attach the pipe to the head first to see if there the same

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Tubing Coupling of Size 2-3/8 EU J55 with API 5CT Standard

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 PCS

- Supply Capability:

- 200000 PCS/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords