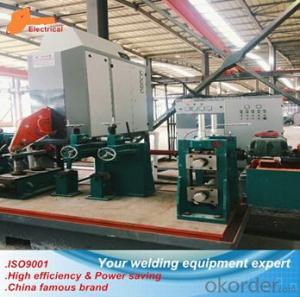

Tube mill high frequency welder air water cooler

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 2 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Condition: New

Type: Industrial Fan Heater

Place of Origin: Hebei, China (Mainland)

Brand Name: CNBM Group

Model Number: GPKL-IICertification: CSA

After-sales Service Provided: Engineers available to service machinery overseas

tech parameter: according to customer's needs

Packaging & Delivery

| Packaging Details: | 1. Standard export wooden package. 2. Fumigated seaworthy wooden boxes 3. Mark as customer's requirement 4. Follow customer's packing standard. |

|---|---|

| Delivery Detail: | 7 days |

Specifications

1.High frequency

2.Certificates: ISO9001;

3.Simply structure;

4.power saving

Circulation Soft Water Cooling System ( air-water cooler)

Mode GPKL-II circulation soft water cooling system adopts closed cooling tower structure. Cooling soft water is flow in sealed water tank and cooling pipes. The inner circulation soft water is cooled by overhead fan and water-spray method using the principle absorbing heat when evaporation. The spray water circulate inside and closed cooling tower`s heat dissipation pipe, spray-water spray at pipes` surface through spray system, some heat is taken by dissipation and soft water temperature inside the pipe go down accordingly. The cut board stops water in hot air and un-evaporated water, make them flow through PVC heat exchange layer, the water in the layer is down by air, then temperature goes sown and fall down to the bottom of the tower.

Apply range: 60 kW –1200 kW induction heating power supply.

Features:

Energy saving: Low investment, small volume, compact frame, convenient installation, easy transfer and without any investment on building cooling pool and cooling tower.

Water saving: Water saving 95% compared with directly water supply cooler.

Electricity saving: Electricity saving above 90% compared with compressor cooling mode.

System adopts sealed soft water circulation, no scale, no jam.

Excellent material, advanced manufacture technics, high heat dissipation efficiency. The equipments dissipation parts adopts high quality of brass & aluminum compound pipe with advanced manufacture technics, brass outer pipe connects hydrophile aluminum platinum fin board in expanding joint mode. Such structure has very large heat dissipation area, high dissipation efficiency, its dissipation ability is far more better than pure aluminum pipe, steel pipe and steel & aluminum fin board.

Best cooling effect due to wind cooling and spray water complex cooling mode. Low temperature in winter, single air cooling can meet production demand, no need to run spray; high temperature in summer, also high water temperature, wind cooling plus spray mode can be used which guarantee some key parts wont damage due to over high water temperature in summer such as SCR, capacitor, reactor, induction coil etc. Therefore prolong using life-span of equipment.

Service

Design as customer's specific demand

Onsite supporting engineer team

Technical consult and guiding

Using environment for H.F. welder

1. Environment requirements

1.1 Indoor installation, heating equipment and heating furnace should earthing well, earthing wire color must be obviously different form control wires, its section area >4mm2, earthing resistance should be no more than 4Ω.

1.2 Height above sea level should be no more than 1000 meters, or else reduce rated value for using.

1.3 Surroundings temperature: 5~40℃.

1.4 Air relative humidity should be no more than 85%.

1.5 No severe vibration, no conductive dust, no various causticity gas and explosion gas.

1.6 Installation gradient should be less than 5°.

1.7 Installed on excellent ventilation situations.

2. Power net requirements

2.1 Power net voltage is sine wave, harmonics distortion should be no more than 5%.

2.2 Imbalance degree between 3-phase voltage should be less than ±5%.

2.3 Power net input voltage is line voltage AC 380V, the constant fluctuation range should be less than ±10%, 2.4 power net frequency variation should be no more than ±2% (i.e. between 49 ~ 51Hz).

- Q:What should be paid attention to when welding the air conditioner copper pipe welding machine?

- 1. Prepare the welding equipment and the necessary fittings and air conditioning copper tubes.2, be sure to clean the parts to be welded and air conditioning copper pipe, so as to ensure the correct solder joints.3, will want to cut the air conditioning copper tube to do the corresponding mark, use copper cutter to cut air conditioning copper tube.4, with both ends of cloth or gauze cleaning air conditioning pipe, until it looks clean. This is done to remove dirt and grease and prevent oxidation.

- Q:What is the welding machine for glass fibre reinforced plastic cable protection tube?

- The glass fiber reinforced plastic material joint is only suitable for bonding and riveting. It can not be welded, so there is no special welding machine.

- Q:Which brand is the best for plastic pipe welding machine? How to ensure the quality of PE pipe welding machine?

- Domestic rings around this brand is pretty good, and many Gas Co designated to use this house

- Q:How to weld the air conditioner copper tube welding?

- How can the air conditioning copper tube and copper pipe be welded?Copper tube and copper tube welding is generally used silver electrode (its silver content is 25%, 15% or 5%) or copper and phosphorus series welding rod, they all have good fluidity, do not need welding flux. Specific welding procedures are as follows:1) welding copper tube processing: expansion and deburring, old copper pipe must also use abrasive paper to remove oxide layer and dirt. When the diameter of the welded copper pipe is different greatly, it is necessary to clamp the pipe with big diameter in order to ensure that the gap between welds should not be too large.2) nitrogen filling: the copper pipe is filled with nitrogen to carry out welding, which can make the inner wall of copper tube bright, clean and oxide free, so as to effectively control the cleanliness of the system.3) open the welding torch, adjust the mixture ratio of oxygen and acetylene, and choose neutral flame.4) first heated by the flame tube insertion, slightly hot after the flame moves outward a little casing, heating the pipe when the pipe joint uniformly heated to the welding temperature (micro solder (red), adding silver electrode or phosphorus brazing). By the solder melting temperature, and flame temperature maintaining outer flame pipe joints, and not using pre solder melt drip welding joints, then heating welding, otherwise it will affect the strength and density of joints.5) remove the flame and close the torch. Check the quality of the weld. If there is a gap or a sand heel in the weld, re weld the weld

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Tube mill high frequency welder air water cooler

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 2 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords