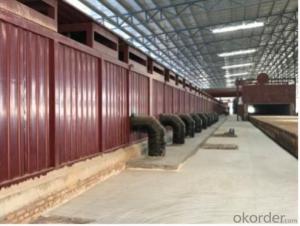

tube dryer

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

tube dryer specifications:

reasonable structure

high efficiency

low energy consumption

convenient transportation

Tube Dryer is formed by rotary body, lifting blade, driving device, supporting device and sealing ring. It can be used for drying many kinds of materials and with convenient and reliable operation; therefore, it has been widely used. The Rotary Dryer is used for drying materials with humidity or granularityin the industries of mineral dressing, building material, metallurgy and chemical.

Dryer main application:

The indirect heat transfer dryer made by our company can be used in building materials, metallurgy, chemical industry, cement plant for drying of limestone slag, coal powder, slag, clay stone.

Dryer usage:

This series drier is used for drying materials with humidity or granularity in the industries of mineral dressing, building material, metallurgy and chemical. Rotating dryer can be used for drying many kinds of materials and with convenient and reliable operation; therefore, it has been widely used.

Dryer features:

Widely used in drying different materials!

reasonable structure,high efficiency

low energy consumption

Specifications of Drier

Specifications (m) | Diameter of rotary body | Length of rotary body | Angle of slope | Weight | Inlet temperature () | Capacity |

GZφ600×6000 | φ600 | 6 | 3 | 2.9 | ≤700 | 0.5-1.5 |

GZφ800×8000 | φ800 | 8 | 5 | 3.5 | ≤700 | 0.8-2.0 |

GZφ1000×9000 | φ1000 | 9 | 5 | 5.2 | ≤700 | 0.8-2.5 |

GZφ1000×10000 | φ1100 | 10 | 5-3 | 5.6 | ≤700 | 1.0-3.5 |

GZφ1200×10000 | φ1200 | 10 | 3-5 | 14.04 | ≤700 | 1.8-5 |

GZφ1200×12000 | φ1200 | 12 | 3-5 | 14.8 | ≤700 | 2-6 |

GZφ1500×12000 | φ1500 | 12 | 3-5 | 17.76 | ≤800 | 3.3-7.5 |

GZφ1800×14000 | φ1800 | 14 | 3-5 | 29 | ≤800 | 5-9 |

GZφ2200×12000 | φ2200 | 12 | 3-5 | 33 | ≤700 | 6-12 |

GZφ2200×18000 | φ2200 | 18 | 3-5 | 53.3 | ≤800 | 10-15 |

GZφ2200×20000 | φ2200 | 20 | 3-5 | 56 | ≤800 | 15-25 |

GZφ3000×20000 | Φ3000 | 20 | 3-5 | 78 | ≤800 | 25 |

GZφ3000×25000 | Φ3000 | 25 | 3-5 | 104.9 | ≤800 | 32-36 |

- Q:What is a combination of drying equipment?

- As we all know, each dryer there are some shortcomings, through the same or two or more models in series, using their own advantages, often play a single device can not achieve the purpose.

- Q:The development prospects of the dryer

- As a compressed air post-processing purification equipment, cold and dry control system will follow the host control technology and continuous improvement. Frequency control, online dew point measurement and control, operating conditions, real-time display and record preservation and so there is a lot of things to do.

- Q:What are the characteristics of the drum dryer?

- conventional direct heating rotary drum dryer conventional direct heating rotary drum dryer in the dry material and hot air Direct contact with the way of convection heat drying in accordance with the direction of flow between the hot air and material, divided into parallel and countercurrent.

- Q:What are the common types of dryers?

- The amount of operating parameters, can be independently controlled, so as to ensure the reliability of the work with dry and operating conditions optimization.

- Q:What are the basic types of common drying equipment?

- (4) hollow paddle dryer (leaf dryer) hollow paddle dry dryer, also known as leaf dryer, mainly by the jacket with the W-shaped shell and two hollow blade shaft and transmission components. A hollow blade is arranged on the shaft and a rotary joint with a heat medium inlet is provided at the shaft end. The heat required to dry the moisture is conducted to the material by the inner wall of the W-shaped groove with the jacket and the hollow leaf wall.

- Q:Frozen sublimation drying equipment which consists of several systems

- the control system: the control system consists of a variety of monitoring the original, an umbrella device, instrumentation and other components, a higher degree of automation control system can be set by the freeze-drying process automatically operate, while the vacuum, heating plate temperature and cooling System monitoring and alarm, record all kinds of data.

- Q:What are the types of drying equipment?

- According to the operating pressure, the dryer is divided into two types of atmospheric pressure dryer and vacuum dryer. Microwave flour sterilization drying equipment can reduce the moisture partial pressure of the space and accelerate the drying process, and can reduce the wet boiling point and material Drying temperature, steam is not easy to leak, so the vacuum dryer for dry heat-sensitive, easy oxidation, explosive and toxic materials and wet steam needs to be recycled occasions.

- Q:How to choose the right drying equipment and drying technology

- Materials can be divided into two kinds of hygroscopic and non-hygroscopic.

- Q:How to solve the dryer a series of failures

- On the other hand, after the dryer was replaced, the dew point immediately peaked, indicating that the dryer was not adequately cooled before it was so well that it could not adsorb moisture well and that the dew point of the dryer would be reduced to normal after cooling. If the dryer is cooled properly, it will cause the temperature to peak. The sudden change in temperature will reduce the drying ability of the desiccant to heat-sensitive materials such as ionomers, amorphous polyesters and certain nylon grades.

- Q:What are the common drying methods?

- In the actual production process, for high-humidity materials are generally as much as possible first with mechanical dehydration method to remove a large number of free water, and then take other drying methods for drying.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

tube dryer

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords