trolley mechanism 11JXF10

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

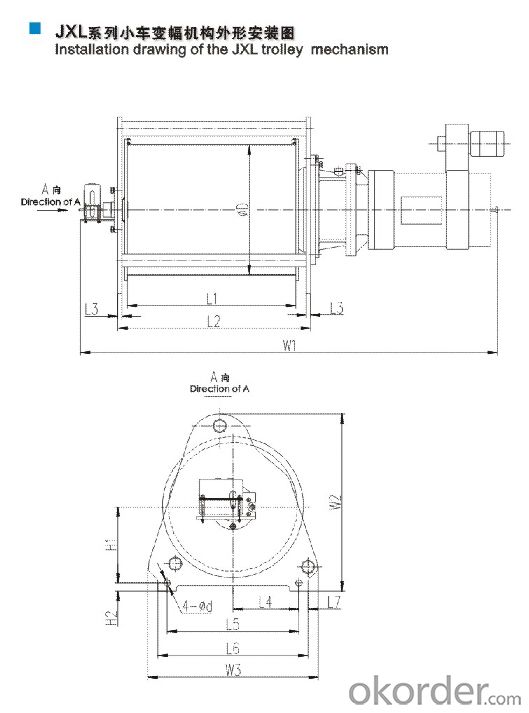

The JXL trolley mechanism is a self-designed new product based on the advanced foreign technology, and got the national utility mode patents.

The JXL trolley mechanism constitutes torque motor, half built-in planetary reduction gear wound roll, rack, and other components, which has advantages of smooth shift from the brake, transmission efficency, low noise, compact structure, and brakeing safe, reliable, accruate positioning, pleasing in appearance, and other characteristics.

After changing variable-frequency speed regulation motor and electronic system, the institutions can be changed to JXF trolley mechanism, which has the advantages of zero velocity brake, starting speed more stable and is more suitable to large tower crane and the trolley running on a demanding place.

Performance parameters

Model:11JXF10

Motor Power(KW):11

Rated single rope tension (N):10000

Single-rope linear velocity(m/min):0-65

Rope capacity(m):83

Wire rope diameter(mm):10

Relevant parameter of the suitable tower crane

--Max lifting load(t):25

--Max crest(m):85

- Q:method how to assemble tower crane?

- Generally tower cranes are self erecting. The first mast and jib sections are assembled at ground level. The mast and jib are then jacked up and another mast section inserted. If the tower crane is not self erecting then mobile cranes have to be used to assemble the crane.

- Q:Calculate how much power the crane has?

- the crane ?? The crane is not defined.

- Q:I've read significance and accordance online. But i can't find a source for defiance, I used epub bud for the other two books but this book isn't on the website. Is there anyway I can read defiance by Shelly Crane online for free?

- tuebl.ca/

- Q:She was editing some of his writings. She was appalled(prim proper Nebraska gal) by his lack of punctuation. He said he didn't have the time for it. He was right. Shortly after he died of TB. Do you ever feel that time is your enemy; that you have only so many years to make a difference?

- To Kill A Mockingbird is my widespread out of those video clips! ineffective night Cowboy and The wonderful Couple are large too! i've got no longer seen Psycho and The Hustler. The Graduate became into basically ok.

- Q:We had a very large tree removed from beside our house. The crane parked in the driveway and caused four very large depressions and crushed concrete.

- Homeowners Insurance cover severe damage to driveway caused by crane? We had a very large tree removed from beside our house. The crane parked in the driveway and caused four very large depressions and crushed concrete.

- Q:I need a answers to these questions for a school project.These questions are:-How and when did it occur when the Siberian White Crane got threatened and critically endangered?What are the causes of this environmental issue?What are the effects of this environmental issue?What has or is being done to prevent such and environmental issue occurring again?Thanks, it will really help me with my final mark.

- Check okorder . There is some very interesting information at this site.

- Q:I was given a CCRadio and I have no idea what it is or what it does.The guy that gave it to me says it's an Awesome DXing radio (whatever that means). The display doesn't work but other than that the radio works fine and pulls in alot of stations the previous owner said. Can anyone help me understand what a CCRadio is and what it does? Thanks to all that contribute.

- C Crane Company sells shortwave receivers. You can use it to listen to shortwave broadcasts, marine weather, NIST time signals, foreign broadcasts, clandestine broadcasts.

- Q:like a really really clear set of instructions. or a video. but evrything i have tried confused me.

- there's a website called origami club that has pretty easy tutorials also tons on youtube.

- Q:if i make 1000 origami cranes what does that mean?doesnt it mean that you get a wish or something? cause i heard a story about it a long time ago but i dont remember. im pretty sure that if you make 1000 cranes you get one wish

- I don't get it. Who's going to grant you a wish? The magic crane genie? Buddha? Why not try praying to God who might be able to help you, without going to all of the work and giving yourself paper cuts.

- Q:the red badge of courage, a novel about the civil war, the verb wrote is A) transitiveB) intransitive

- Transitive - because it has an object The Red Badge of Courage. . Generally, if you can put the word something after a verb, it is transitive. Stephen Crane wrote something .

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

trolley mechanism 11JXF10

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords