Tripod & Beam Clamp for building construction

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Steel Prop & Tripod & Beam Clamp

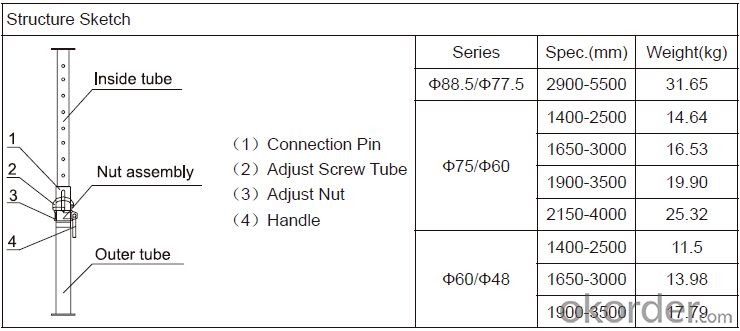

(1) Steel prop is a vertical support system widely used in construction.

Characteristics:

◆ Simple & flexible structure

◆ Easy & fast operation

◆ Economical efficiency

◆ Easy storage and transportation

◆ Reasonable load-bearing capacity

(2) Tripod is always used as support for steel prop.

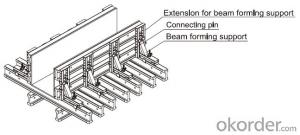

(3) The beam clamp is a technical instrument for supporting beam formwork

which makes conventional beam formwork simple, and increases the construction

efficiency.

Characteristics:

◆ Flexible structure

◆ Optimum design proposal

- Q:Do steel props have any height indicators for easy adjustment?

- Steel props usually come with height indicators to facilitate adjustment. These indicators are commonly found on the prop's outer surface and serve the purpose of establishing and setting the desired height. This enables swift and precise adjustment of the steel prop to meet the necessary height requirements when constructing or renovating structures. The height indicators may appear as numbers, lines, or other visual markers that represent various height positions. These indicators play a crucial role in ensuring the accurate positioning of the steel props, guaranteeing optimal support and stability. Additionally, they simplify the task of construction workers, making it more convenient for them to adjust and align the props as necessary.

- Q:Are steel props suitable for use in bridge construction?

- Bridge construction can benefit from the use of steel props. These props, also called adjustable steel props or steel shores, are commonly employed in construction projects to provide temporary load-bearing support and structural stability. Their durability and strength are ensured by their high-quality steel composition. Furthermore, their adjustability allows for customization based on the specific needs of the bridge construction project, accommodating various loads and heights. The load-bearing capacity of steel props is a notable advantage in bridge construction. They effectively support heavy loads and distribute weight, ensuring the stability and safety of the bridge structure. Withstanding high-pressure forces, they provide necessary reinforcement during different construction phases, such as formwork, concrete pouring, and beam installation. Apart from their load-bearing capacity, steel props are relatively lightweight, facilitating ease of handling and transportation on the construction site. Their modular design allows for quick assembly and disassembly, saving time and labor costs. Additionally, they are reusable, making them a cost-effective choice for bridge construction projects. In conclusion, steel props offer several advantages that make them suitable for bridge construction. Their strength, adaptability, load-bearing capacity, and cost-effectiveness make them a reliable choice for providing temporary support and reinforcement during the construction of bridges.

- Q:Can steel props be used in supporting precast concrete elements during installation?

- Yes, steel props can be used to support precast concrete elements during installation. Steel props, also known as adjustable steel props or adjustable steel shores, are commonly used in construction to provide temporary support to structures or elements. They are particularly useful in supporting precast concrete elements due to their strength, adjustability, and stability. During the installation of precast concrete elements, steel props are typically positioned underneath the elements to provide vertical support and prevent them from sagging or collapsing. The props can be easily adjusted in height to accommodate varying elevations or to ensure a level installation. This adjustability is especially beneficial when dealing with uneven ground conditions or when aligning multiple precast elements. Steel props are designed to withstand heavy loads and provide a reliable support system for the precast concrete elements. They are usually made of high-quality steel with a robust construction, allowing them to bear the weight of the elements without deformation or failure. In addition to their strength and adjustability, steel props offer stability during the installation process. They are equipped with base plates or feet that provide a solid foundation, ensuring that the props remain securely in place. This stability is crucial to prevent any unexpected movement or shifting of the precast elements, which could lead to damage or safety hazards. Overall, steel props are a suitable choice for supporting precast concrete elements during installation. Their strength, adjustability, and stability make them a reliable and efficient solution for ensuring a successful and safe installation process.

- Q:Are steel props cost-effective compared to other support systems?

- Yes, steel props can be considered cost-effective compared to other support systems for various reasons. Firstly, steel props are highly durable and have a longer lifespan compared to other materials such as timber or aluminum. This means that they can be reused multiple times, reducing the need for frequent replacements and ultimately saving costs in the long run. Additionally, steel props are known for their high load-bearing capacity, providing reliable support for heavy structures. This can result in fewer props being needed compared to other support systems, reducing the overall cost of materials required for a project. Moreover, steel props are adjustable in height, allowing for versatility and adaptability in various construction scenarios. This flexibility eliminates the need for custom-made supports, which can be costly and time-consuming. Furthermore, steel props are relatively easy to install, dismantle, and transport due to their lightweight and modular design. This can significantly reduce labor costs and time spent on construction sites. Lastly, steel is a widely available and cost-effective material, making steel props more affordable compared to support systems made from materials that are scarce or expensive. Taking all these factors into account, it can be concluded that steel props are a cost-effective choice for support systems in construction projects, offering durability, versatility, and efficiency while minimizing overall expenses.

- Q:How to reinforce the lower part of the construction elevator on the garage roof

- The coefficient is close to 5 tons 50KN lifting conditions consider the edge pressure of the pressure to be more load release plate can put beam line can arrange the column even if the column double foundation

- Q:Can steel props be used in underwater construction projects?

- Yes, steel props can be used in underwater construction projects. Steel is a durable and strong material that can withstand the corrosive effects of water. It is commonly used in underwater construction projects for its structural stability and ability to support heavy loads.

- Q:What is the weight of a typical steel prop?

- The size and specifications of a typical steel prop can cause its weight to fluctuate. On average, a standard steel prop generally falls between 10 and 15 kilograms (22 to 33 pounds) in weight. It is crucial to understand that the weight can differ due to factors like the prop's length, diameter, and the materials used in its construction.

- Q:Can steel props be used in hospital renovation projects?

- Yes, steel props can be used in hospital renovation projects. Steel props are commonly used in construction and renovation projects to provide temporary support to structures. They are adjustable and can be easily installed, making them suitable for various applications, including hospital renovations. Steel props can be used to support ceilings, walls, and floors during renovation work, ensuring the safety and stability of the building. Additionally, they can be adjusted to the required height, allowing for flexibility in accommodating different project needs. Therefore, steel props are a reliable and efficient solution for hospital renovation projects.

- Q:How do steel props contribute to the prevention of structural vibrations?

- Steel props contribute to the prevention of structural vibrations by providing additional support and stability to the structure. These props act as temporary supports during construction or renovation works and are usually placed vertically to support beams, walls, or other structural elements. One of the main causes of structural vibrations is insufficient support or inadequate stiffness of the structure. When a structure is not properly supported, it can experience excessive movement or vibrations, which can be detrimental to its overall stability and safety. Steel props help to alleviate this issue by providing additional support, increasing the stiffness of the structure, and reducing the potential for vibrations. By placing steel props strategically at key locations, they can effectively distribute the weight and load of the structure, ensuring that it remains stable and resistant to vibrations. The props act as temporary columns, transferring the load from the structure to the ground, and minimizing any excessive movement or oscillation. Moreover, steel props are adjustable, allowing for precise positioning and fine-tuning of the support. This adjustability feature allows construction professionals to tailor the props to the specific requirements of the structure, ensuring optimal support and minimizing vibrations. In conclusion, steel props play a crucial role in the prevention of structural vibrations by providing additional support, increasing the stiffness of the structure, and minimizing excessive movement. Their adjustability and versatility make them an essential tool in construction and renovation projects, ensuring the safety and stability of structures.

- Q:Scaffolding steel pipe support spacing

- Open type double row steel pipe scaffolding pole spacing 1.05, 1.30, 1.55M.Open type single row steel pipe scaffolding pole spacing 1.20, 1.40M.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Tripod & Beam Clamp for building construction

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products