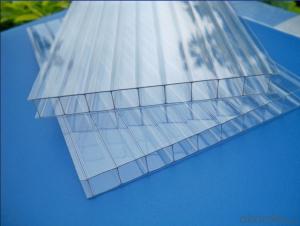

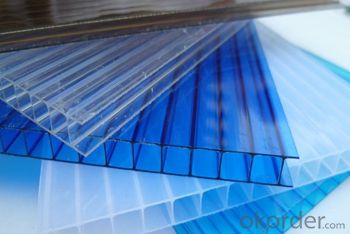

Triple-wall Polycarbonate Hollow SheetThe Tensile Yield Strength:≥60MPa

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Category

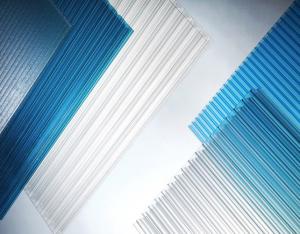

1.PC hollow sheet series

Twin wall PC hollow sheet

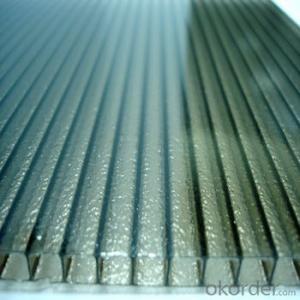

Triple wall PC hollow sheet

Four wall PC hollow sheet

Honeycomb PC hollow sheet

X-profile PC hollow sheet

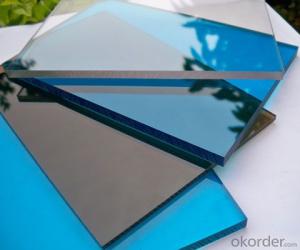

2. PC solid Sheet series

PC solid sheet

PC light diffusion sheet

PC particle board

PC frosted panel

PC film

PC corrugated plate

Polycarbonate Sheet Sunshine Board

Product Specification

u Appearance: board face feel is smooth, level off, no distortion, no bubbles,

u Weight, size: in accordance with customer requirements

u Colors: clear, lake blue, green, blue, opal, brown, silvery gray, red Conventional etc.

u The tensile yield strength:≥60MPa

u The bending strength: ≥80MPa

u Shaw hardness: ≥80D:

u The thermal deformation temperature:(1.80MPa)≥125

u Thermal expansion coefficient:(-30℃—+30℃),℃-1≤6.5*10-5

u Transmission (8 mm):≥75%

u Transmission (solid sheet 3 mm):≥80%

Polycarbonate three wall hollow sheet

Thickness: 10mm / 12mm / 14mm / 16mm

Width: 2100mm

Features:

1) Light transmission: Up to88%

2) Impact resistance: 80 times that of glass, 15 times that of acrylic sheeting

3) Temperature resistance range: -40 ~ 120°, C

4) Light weight: Only 1/12 of the weight of glass of the same thickness

5) Ultraviolet resistance: With UV protective layer

6) Flame resistance: Rated class B1

7) Sound and heat proof

- Q:PC sun panels and color steel plate how to bond

- In fact, with a little bit of weather resistance can be plastic, completely unnecessary Bolts, try HTACK7, you can use self-tapping or bolts, and then neutral sealant;

- Q:Company pc sunshine board how to solve the problem

- The traditional disposal: pc sun plate endurance board with a wide aluminum alloy bar, and then use a good quality neutral sealant in the pressure on both sides of the thickness of 5 mm width of 5-8 mm silicone.

- Q:What can I do with my own sunshine board?

- PC sunshine board product range 1, office buildings, department stores, hotels, villas, schools, hospitals, sports venues, entertainment centers and public facilities of the lighting ceiling 2, the highway highway viaduct noise barriers 3, agricultural greenhouse, flower greenhouse and indoor pool of the sky 4, subway entrance, station, parking lot, shopping malls, pavilions, restrooms, corridors and other canopy 5, bank anti-theft counters, jewelry store anti-theft window, police explosion shield 6, advertising light boxes, bus station panels, advertising display cards 7, office, home indoor partition, pedestrian access, fence, balcony, shower and so on

- Q:What is the difference between PC stamina and PC sunboard?

- In addition, the use of sun panels and endurance boards are the same in many ways, but there are also differences, such as sun panels are generally used in the stadium lighting roof, greenhouse lighting ceiling, warehouse lighting roof and so on. Stamina board is used to make shields, outdoor light boxes, advertising signs, etc. are more common. So customers in the choice of PC sun panels, PC Nai Liban or need to be based on their actual use and needs to choose.

- Q:Can the sun board bend?

- Can be cold bending, but the minimum radius of cold bending does not exceed the thickness of the sunboard 175 times, as said 90 degrees like the bend is certainly not possible. Stamina can, but can not be cold fold, need to be thermoformed.

- Q:What is the difference between a hollow board and a sunboard?

- Sunshine board is one of the lighting board, most of the lighting board is made of FRP and the sun is made of PC (polycarbonate) made, a little PC board warranty period is 10 years and 15 years, The better FRP lighting board warranty period of 20 years, 25 years. Performance comparison, although the thermal conductivity of the lighting board than the sun board is low, but the lighting board is usually a single layer, thermal conductivity than the sun plate. That is the summer sun exposure, then, under the lighting board room temperature to be higher. Light transmittance, carrying capacity under normal circumstances 2 can meet.

- Q:Project sun board price how much

- Shanghai Jie resistant engineering PC sunshine board price is not constant price, but a comprehensive consideration of technical level, sheet performance, then the raw material prices and other costs through the calculation.

- Q:Where the PC stamina board and the sun board sell more price is also cheaper

- Not the cheapest, only cheaper, but the life is slightly shorter.

- Q:What is the difference between the PC and the PC board?

- Sometimes the particles may be slightly cheaper, because its surface is uneven, with less raw materials so the cost will be low.

- Q:How much of the installation of the sun board installation of a square meter

- This assembly system is mainly used for small facilities such as garage, station canopy, rain eaves, greenhouses and many other alternative glass occasions. When using the wet assembly method, as shown in Figure 2, the basic requirement is that the sealing system is able to withstand a certain amount of movement of the plate, allowing thermal expansion without reducing its adhesion to the frame and the plate. It is generally recommended to use a neutral silicone adhesive and a wet sunboard assembly, but it is important to note that the chemical properties of the sealant used must be checked before use, and acid and alkaline silicone adhesives must not be used because these curing agents Plate cracking, especially when there is internal stress, the choice of sealant, in addition to considering chemical adaptability, but also focus on testing, elongation and weather resistance.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Triple-wall Polycarbonate Hollow SheetThe Tensile Yield Strength:≥60MPa

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords